I-Tungsten Carbide Flow Drill Bit

INCAZELO YOMKHIQIZO

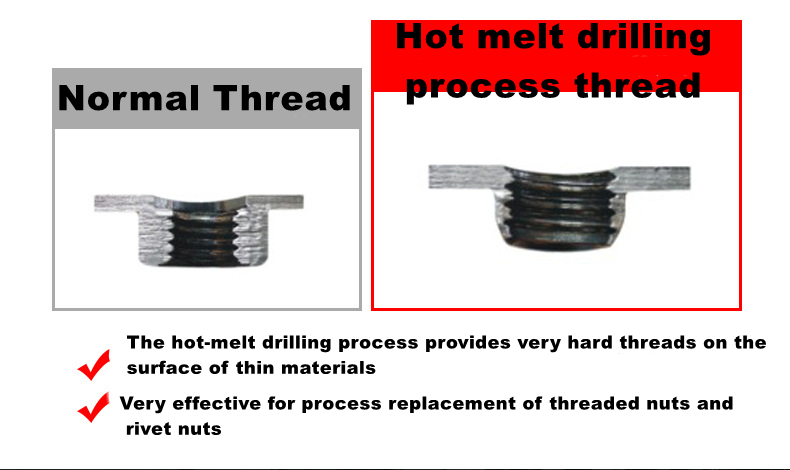

Isimiso sokumba i-hot melt

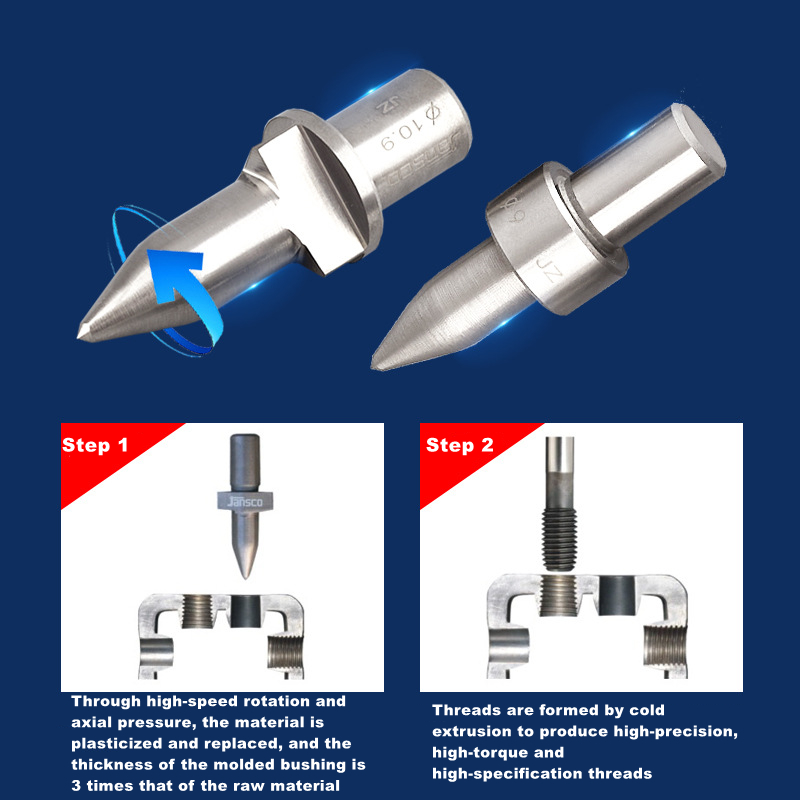

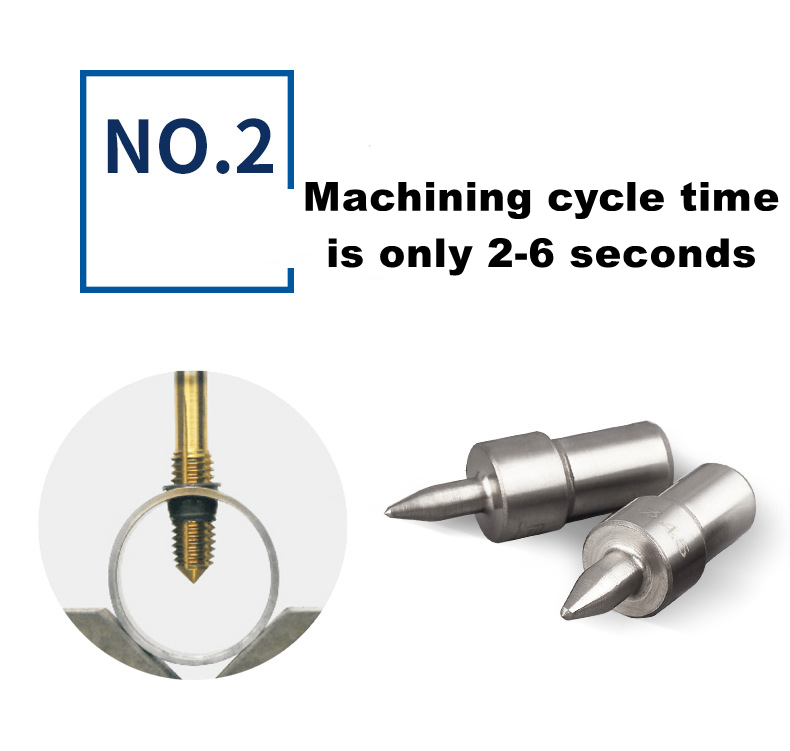

I-hot-melt drill ikhiqiza ukushisa ngokuzungezisa ngesivinini esikhulu kanye ne-axial pressure friction ukwenza ipulasitiki bese ibuyisela impahla. Ngesikhathi esifanayo, ishaya futhi yakhe isihlahla cishe izikhathi ezi-3 ubukhulu bempahla eluhlaza, futhi ikhiphe futhi icofe empompini ukuze yenze into encane. Ukunemba okuphezulu, izintambo eziqine kakhulu.

ISINCOMO SOKUSETSHENZISWA EZINKUFUNDENI

Isinyathelo sokuqala: ukufaka ipulasitiki izinto ngokuzungeza ngesivinini esikhulu kanye ne-axial pressure. Ubukhulu besihlahla esibunjiwe buphindwe izikhathi ezi-3 kunempahla eluhlaza.

Isinyathelo sesibili: intambo yenziwa nge-extrusion ebandayo ukuze ikhiqize ukunemba okuphezulu, i-torque ephezulu kanye ne-high-specificatio.n imicu

| Ibhrendi | I-MSK | Ukugqoka | No |

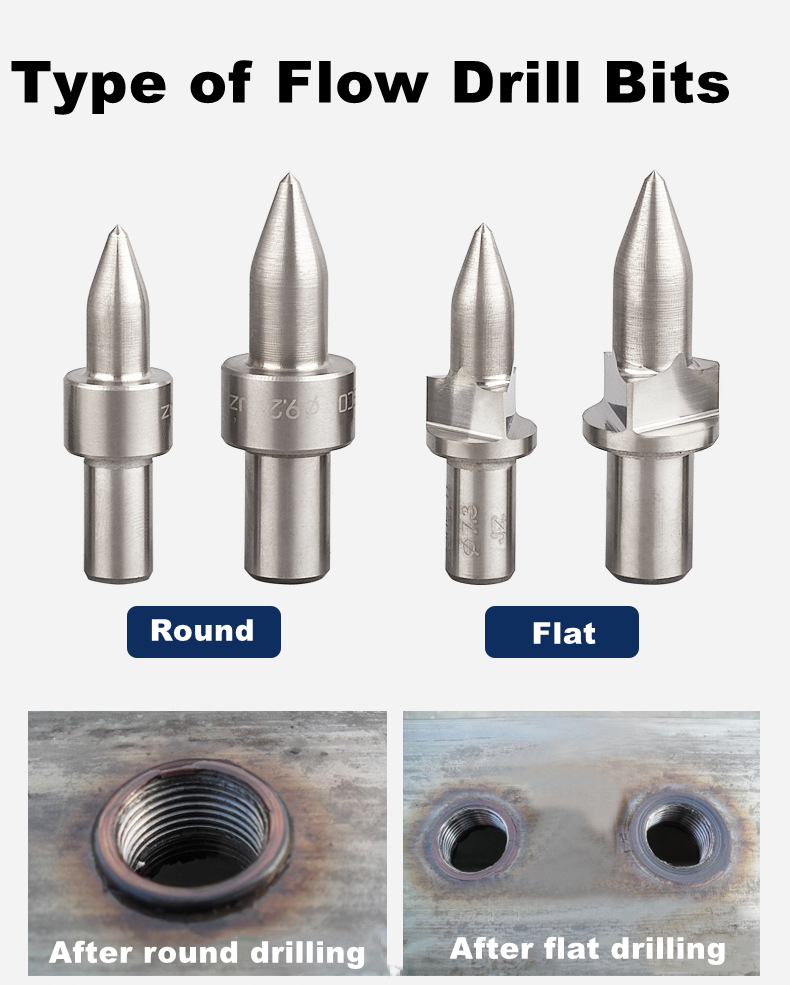

| Igama Lomkhiqizo | I-Thermal Friction Drill Bit Set | Uhlobo | Uhlobo lwe-Flat/Round |

| Okubalulekile | I-Carbide Tungsten | Sebenzisa | Ukubhoboza |

ISICI

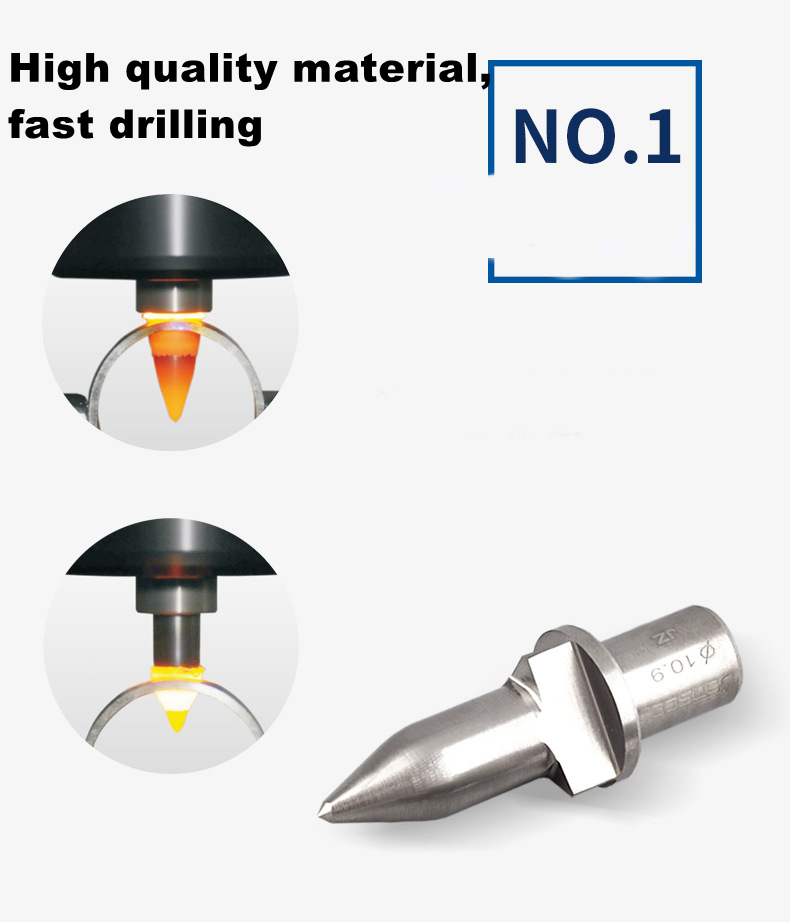

Izinyathelo zokuqapha ukusetshenziswa kwe-hot melt drill:

1. I-workpiece impahla: i-hot melt drill ifaneleka ukucubungula izinto ezihlukahlukene zensimbi ezinobubanzi obungu-1.8-32mm nobukhulu bodonga obungu-0.8-4mm, njengensimbi, insimbi emnene, insimbi engagqwali, i-titanium, i-aluminium, ithusi, ithusi, ithusi (okuqukethwe kwe-Zn ngaphansi kuka-40%), i-aluminium engaphansi, i-aluminium engaphansi, ingxube eqinile, njll. mfishane impilo ye-hot melt drill.

2. Inhlama yokuncibilika okushisayo: Lapho i-hot-melt drill isebenza, izinga lokushisa eliphezulu elingaphezu kwama-degree angu-600 liyakhiqizwa ngokushesha. I-hot melt paste ekhethekile ingandisa impilo yesevisi ye-hot-melt drill, ithuthukise ikhwalithi yendawo yangaphakathi yesilinda, futhi ikhiqize umumo wonqenqema ohlanzekile nowanelisayo. Kunconywa ukuthi wengeze inani elincane lokunamathisela okuncibilika okushisayo ethuluzini kuzo zonke izimbobo ezi-2-5 ezimbozwe nge-carbon steel evamile; ngensimbi engagqwali workpieces, imbobo ngayinye yamba, engeza hot melt unama ngesandla; ukuqina nokuqina kwempahla, kuyanda imvamisa yokwengeza.

3. I-shank ne-chuck ye-hot melt drill: Uma ungekho usinki wokushisa okhethekile, sebenzisa umoya ocindezelwe ukuze uphole.

4. Imishini yomshini wokumba: inqobo nje uma imishini ehlukahlukene yokumba, imishini yokugaya kanye nezikhungo zomshini ezinejubane elifanele namandla zifaneleka ekubholeni okuncibilika okushisayo; Ubukhulu bezinto ezibonakalayo kanye nomehluko wento ngokwayo konke kuthinta ukuzimisela kwejubane lokujikeleza.

5. Izimbobo ezenziwe ngaphambilini: Ngokumba kusengaphambili imbobo encane yokuqala, ukuguqulwa kwe-workpiece kungagwenywa. Izimbobo ezenziwe ngaphambilini zinganciphisa amandla e-axial kanye nokuphakama kwesilinda, futhi zingaphinda zikhiqize unqenqema oluyisicaba ekugcineni ekugcineni kwesilinda ukuze kugwenywe ukugoba kokwakheka kwezinto zokusebenza ezinezindonga ezincane (ezingaphansi kuka-1.5mm).

6. Uma ushaya, sebenzisa amafutha okugcoba: kunconywa ukusebenzisa ompompi be-extrusion, abangakhiwe ngokusika kodwa nge-extrusion, ngakho-ke banamandla amakhulu okudonsa kanye nenani le-torsion. Kungenzeka futhi ukusebenzisa ompompi abavamile bokusika, kodwa kulula ukusika isilinda, futhi ububanzi be-hot-melt drill buhlukile futhi budinga ukwenziwa ngokwehlukana.

7. Ukugcinwa kwe-hot-melt drill: Ngemva kokuba i-hot-melt drill isisetshenziswe isikhathi esithile, indawo engaphezulu izogqokwa, futhi okunye okunamathiswa okuncibilika okushisayo noma ukungcola kwe-workpiece kuzoxhunywa emzimbeni womsiki. Bopha i-hot melt drill ku-chuck ye-lathe noma umshini wokugaya, bese uyigaya ngokunamathisela okulimazayo. Ungakunaki ukuphepha.