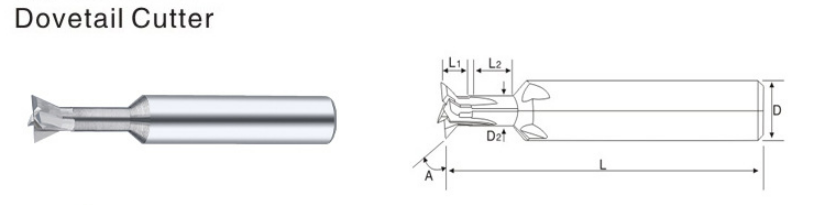

Ithuluzi le-Tungsten Carbide Dovetail Milling Cutters

Yonke into yenziwe ngensimbi ye-tungsten yekhwalithi ephezulu, enobunzima obuphezulu nokumelana nokugqoka okuphezulu. Ukusetshenziswa kwezinto eziphezulu zensimbi ye-alloy, enokumelana okuhle nokuzamazama komhlaba.Yenziwe ngezinsimbi ezintsha zensimbi ze-tungsten, ezinokumelana nokugqoka okuphezulu namandla. Kuwummese we-dovetail wekhwalithi ephezulu wezinhlelo zokusebenza zokusika ezinesivinini esiphezulu. Ingenza ukucubungula kwesivinini esikhulu kunsimbi engagqwali, ingxubevange ye-aluminium, insimbi ecijile nezinye izinto ezingaphansi kwe-HRC55 (kuhlanganise ne-HRC55). Ukwenza imishini, ukunciphisa inani lezinguquko zamathuluzi kanye nokwenza ngcono ukusebenza kahle

Inzuzo:

Ibiza kakhulu futhi sikhetha insimbi ye-tungsten yekhwalithi ephezulu enobulukhuni obuphezulu nokumelana nokugqokwa okuphezulu

Ukwakhiwa komshini wokunemba, ukugaya kahle. Ukucubungula okunembayo, ama-burrs amancane ekucutshungulweni komkhiqizo-ukushelela okuphezulu

Ukulawulwa kwekhwalithi okuqinile, ukunemba okuphezulu kanye nemikhiqizo eqediwe ebukhali

Isici:

1. Ama-engeli abukhali athuthukisa kakhulu ukusika ukusebenza kahle

2. Idizayini ye-groove eqondile, ukukhishwa kwe-chip okubushelelezi ngaphandle kokunamathela emmese

3. Gwema umoya ngokunengqondo futhi andise impilo yamathuluzi

4. Qinisa ukuqina konqenqema lokusika, futhi ibhande le-arc edge lihambisa emaphethelweni abukhali futhi lisuse ngempumelelo i-burr.

5. I-groove yokukhishwa kwe-chip enkulu yomthamo inqamula amandla, futhi ukusika kuhamba kahle, ukufeza ukusebenza kahle kwemishini, futhi ucezu lokusebenza lunembe kakhulu futhi lumangalisa kakhulu.

| Uhlobo | I-Tungsten Dovetail Milling Cutter | Okubalulekile | Insimbi ye-Tungsten |

| I-Workpiece Material | Insimbi engagqwali, i-aluminium, i-die steel, i-cast iron, i-aluminium alloy, i-alloy steel, i-titanium alloy, njll. | Ithuluzi lomshini elisebenzayo | Isikhungo somshini we-CNC, ithuluzi lomshini we-CNC, umshini wokuqopha, umshini wokuqopha, umshini onesivinini esikhulu |

| Iphakheji Yezokuthutha | Ibhokisi | Umtshingo | 3/4 |

| Ukugqoka | No | Ukuqina | <=55 |

| Ububanzi beFlute(mm) | I-D2(mm) | L2(mm) | Ubude beFlute(mm) | I-Shank Diameter(mm) | Ubude Obuphelele(mm) | Imitshingo |

| 3 | 1.5 | 5 | 0.7 | 3 | 50 | 3 |

| 4 | 2 | 6 | 1 | 4 | 50 | 3 |

| 5 | 2.5 | 8 | 1.2 | 5 | 50 | 3 |

| 6 | 3 | 8 | 1.5 | 6 | 50 | 3 |

| 7 | 3.5 | 10 | 1.7 | 7 | 50 | 4 |

| 8 | 4 | 10 | 2 | 8 | 50 | 4 |

| 9 | 4.5 | 15 | 2.2 | 9 | 60 | 4 |

| 10 | 5 | 15 | 2.5 | 10 | 60 | 4 |

| 11 | 5.5 | 15 | 2.7 | 11 | 60 | 4 |

| 12 | 6 | 15 | 3 | 12 | 60 | 4 |

| 16 | 8 | 20 | 4 | 16 | 65 | 4 |

| 20 | 10 | 25 | 5 | 20 | 75 | 4 |

| 3 | 1.5 | 5 | 1.4 | 3 | 50 | 3 |

| 4 | 2 | 6 | 1.7 | 4 | 50 | 3 |

| 5 | 2.5 | 8 | 2.1 | 5 | 50 | 3 |

| 6 | 3 | 8 | 2.6 | 6 | 50 | 3 |

| 7 | 3.5 | 10 | 3 | 7 | 60 | 4 |

| 8 | 4 | 10 | 3.4 | 8 | 60 | 4 |

| 9 | 4.5 | 15 | 3.8 | 9 | 60 | 4 |

| 10 | 5 | 15 | 4.3 | 10 | 60 | 4 |

| 11 | 5.5 | 15 | 4.7 | 11 | 60 | 4 |

| 12 | 6 | 15 | 5.2 | 12 | 60 | 4 |

| 16 | 8 | 20 | 6.9 | 16 | 65 | 4 |

| 20 | 10 | 25 | 8.6 | 20 | 70 | 4 |

| 3 | 1.5 | 5 | 2.7 | 3 | 50 | 3 |

| 4 | 2 | 6 | 3.7 | 4 | 50 | 3 |

| 5 | 2.5 | 8 | 4.6 | 5 | 50 | 3 |

| 6 | 3 | 8 | 5.5 | 6 | 50 | 3 |

| 7 | 3.5 | 10 | 6.5 | 7 | 60 | 4 |

| 8 | 4 | 10 | 7.4 | 8 | 60 | 4 |

| 9 | 4.5 | 15 | 8.3 | 9 | 60 | 4 |

| 10 | 5 | 15 | 9.3 | 10 | 60 | 4 |

| 11 | 5.5 | 15 | 10.2 | 11 | 60 | 4 |

| 12 | 6 | 15 | 11.1 | 12 | 60 | 4 |

| 16 | 8 | 20 | 14.9 | 16 | 65 | 4 |

| 20 | 10 | 25 | 18.6 | 20 | 75 | 4 |

Sebenzisa:

Kusetshenziswa kabanzi emikhakheni eminingi

Aviation Manufacturing

Ukukhiqizwa Kwemishini

Umkhiqizi wezimoto

Ukwenza isikhunta

Ukukhiqiza Ugesi

I-Lathe processing