Carbide T-slot End Mill Cutter Fresas Para Ranura Cuadros Tipo T

INCAZELO YOMKHIQIZO

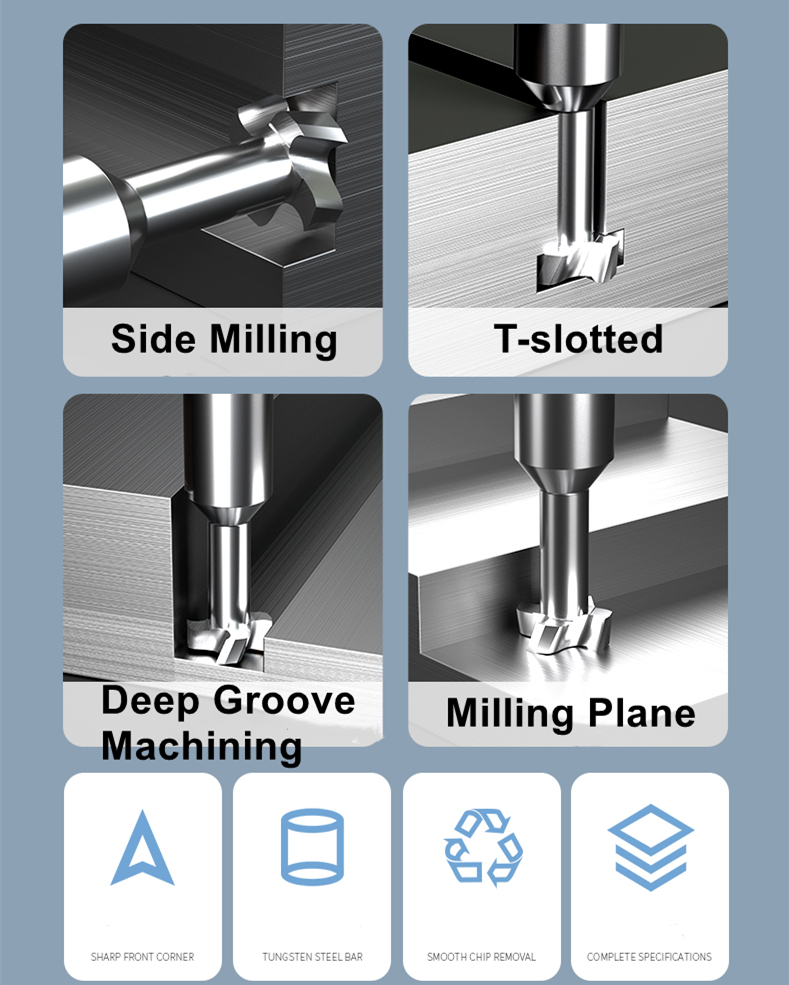

Ukusebenza okuphezulu kwe-T-slot milling enezinga eliphezulu lokuphakelayo kanye nokujula kokusika. Futhi ifanele umshini ongezansi we-groove ezinhlelweni zokugaya eziyindilinga. Ukufakwa okufakwe kahle okufakwe inkomba okugunyazayo ukususwa kwe-chip okuhambisana nokusebenza okuphezulu ngaso sonke isikhathi.

Idizayini ekhethekile ye-helical groove ephezulu, ehambisana nomklamo onengqondo wokugwema umoya, iyenza ibe nesikhala esikhulu sokukhipha i-chip, okwenza ukukhishwa kwe-chip kube bushelelezi ngesikhathi sokusika.

Izici eziyinhloko:

Kuyithuluzi elikhethekile lokucubungula ama-T-slots. Ngemuva kokuthi kugaywe ama-grooves aqondile, ama-T-slots anembayo edingekayo angagaywa ngesikhathi esisodwa. Umkhawulo wokugcina we-milling cutter une-engeli yokusika efanelekile. ukunemba okuphezulu nokucwebezela.

I-T-slot milling cutter (eyaziwa nangokuthi i-T-slot milling cutter, i-waist slot milling cutter)

Izici ze-T-slot milling cutter: ama-grooves ahlukahlukene ayisikwele, ama-grooves ayindilinga, ama-grooves amise okukhethekile, njll., athuthukisa kakhulu ukucubungula ukusebenza kahle ekukhiqizeni;

I-T-slot milling cutter material: i-carbide, i-V-welding, i-powder metallurgy, i-welding alloy inserts, njll.;

Ukufakwa kwe-T-slot milling cutter: ukugqoka kuyakhethwa, futhi ukumboza kucacisiwe ngokuvumelana nezimo zokusebenza zempahla yomkhiqizo;

Izimboni eziyinhloko ze-T-slot milling cutter: izingxenye zezimoto, i-electronics, imithi, izindiza, imishini yokwakha kanye neminye imikhakha eminingi;

Izinto zokusika i-T-slot milling cutter: izinsimbi ezingezona ayoni (i-aluminium alloy, ithusi), insimbi ecijile, insimbi yengxubevange, insimbi ephansi ye-carbon, insimbi eqinile, insimbi engagqwali, kanye nezinto ezihlukahlukene okunzima ukuzisebenzisa umshini;

ISINCOMO SOKUSETSHENZISWA EZINKUFUNDENI

1. Imigoqo yensimbi ye-tungsten engenisiwe ikhethiwe, enobulukhuni obuphezulu nokumelana nokugqokwa, imimese ebukhali futhi akulula ukuyifinyelela, nempilo ende yesevisi.

2. Idizayini ye-Cutter edge, ubuciko obuyindilinga, ukukhetha okuhle kakhulu kwezinto, kanye nomklamo omkhulu wokusika kuthuthukisa kakhulu ukushelela.

3. I-blade ebukhali. Unqenqema lokusika lubukhali, okwenza ukusika kube bushelelezi, futhi umklamo wokulwa nokudlidliza wonqenqema lokusika ungathuthukisa ngempumelelo ukuzinza kokucubungula kanye nekhwalithi yendawo.

4. Idizayini ye-chamfer, usayizi ojwayelekile we-chamfer, i-chamfer engu-45 degree, i-contour eyindilinga nebushelelezi, okwenza kube lula ukuyifaka.

| Ibhrendi | I-MSK | Okubalulekile | Insimbi yokufa; Insimbi; insimbi ye-carbon; insimbi ye-alloy |

| Igama Lomkhiqizo | T-slot End Mill Cutter | Iphakheji | Ibhokisi Lepulasitiki |

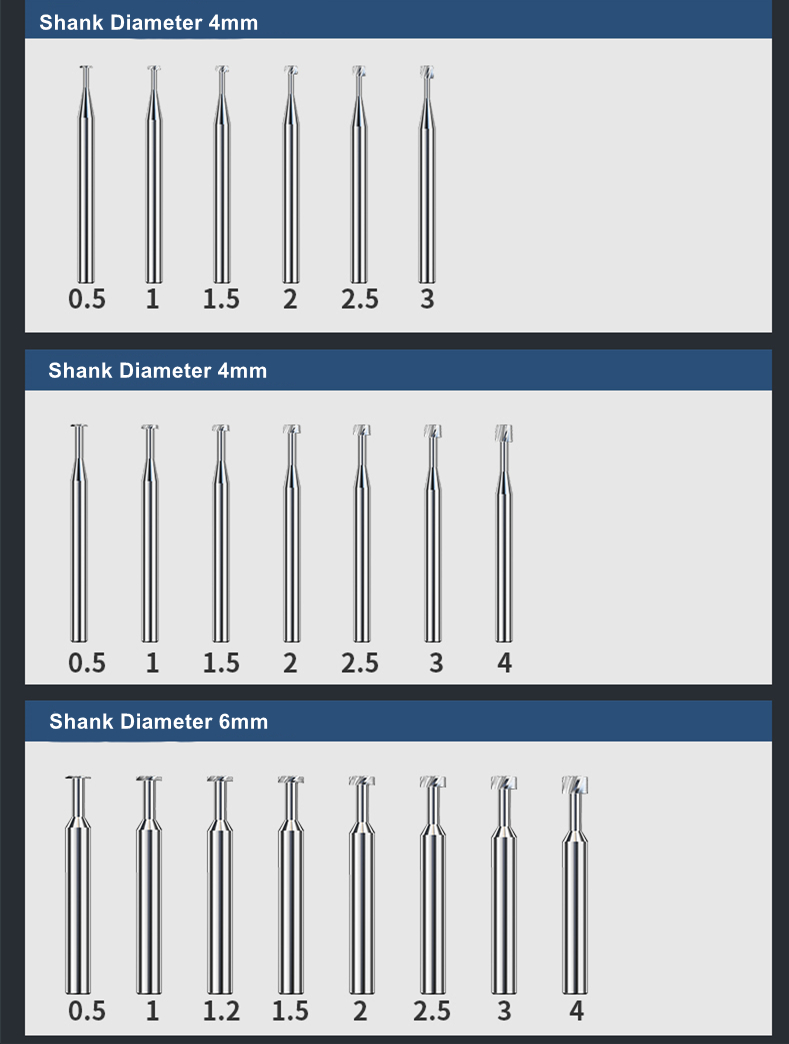

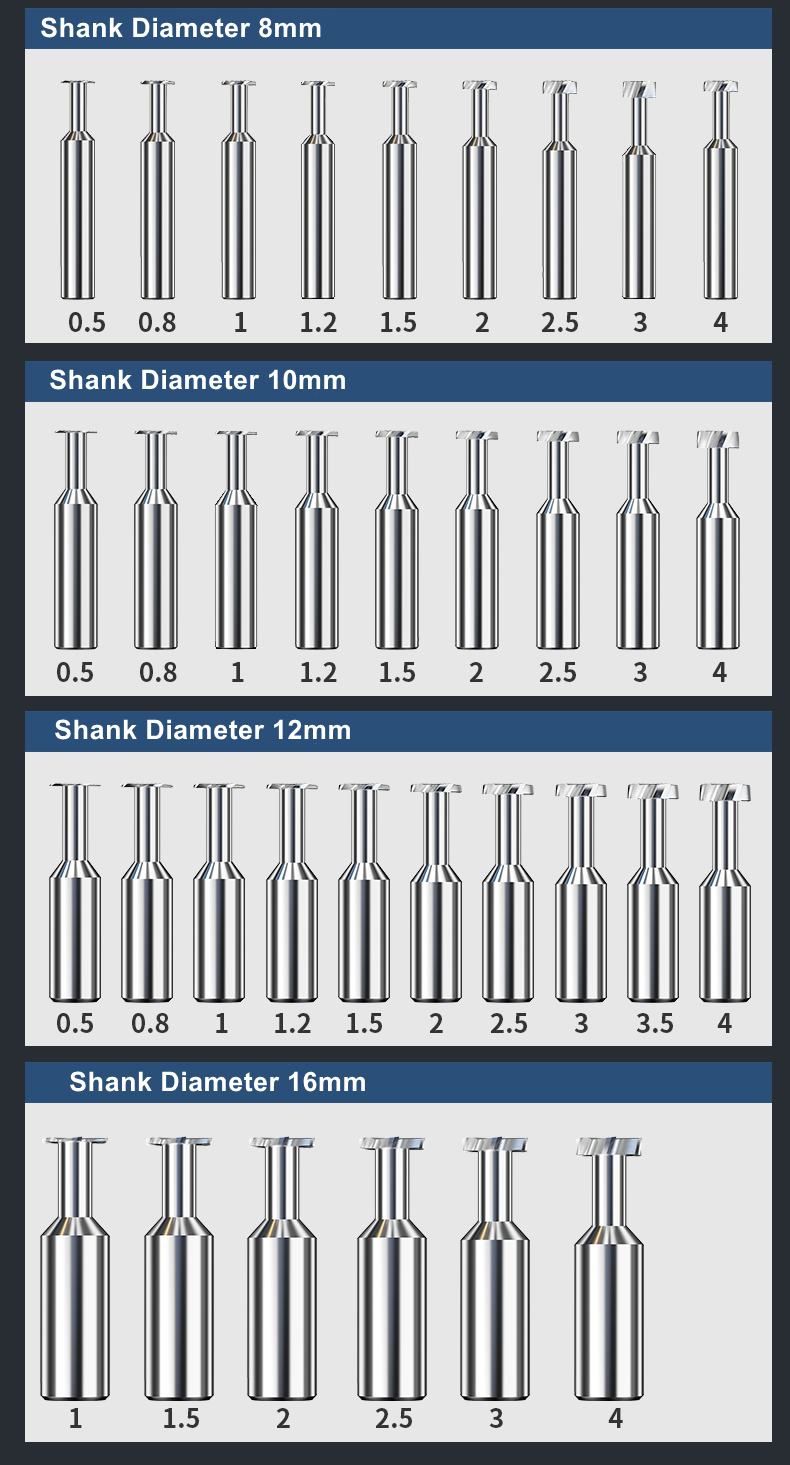

Izithombe ezinemininingwane