Njengethuluzi elivamile lokucubungula izintambo zangaphakathi, ompompi bangahlukaniswa ngompompi be-spiral groove, ompompi bokuthambekela onqenqemeni, ompompi be-groove abaqondile kanye nompompi bentambo yamapayipi ngokuya ngokuma kwabo, futhi bangahlukaniswa ngompompi bezandla kanye nompompi bemishini ngokuya ngendawo yokusetshenziswa. Ihlukaniswe ngama-metric, ama-American, kanye nompompi basebukhosini. Ingabe ujwayelene nabo bonke?

01 Thepha ngezigaba

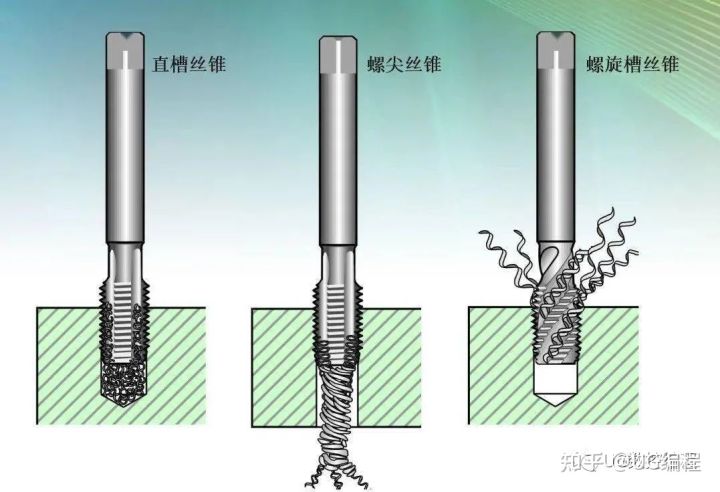

(1) Ukusika ompompi

1) Umpompi womtshingo oqondile: isetshenziselwa ukucubungula ngokusebenzisa izimbobo nezimbobo eziyizimpumputhe, ama-iron chips akhona ku-groove kampompi, ikhwalithi yentambo ecutshungulwayo ayiphezulu, futhi isetshenziselwa kakhulu ukucubungula izinto ezimfushane ze-chip, njenge-grey cast iron, njll.

2) I-Spiral groove tap: isetshenziselwa ukucubungula imbobo eyimpumputhe ngokujula kwembobo okungaphansi noma okulingana ne-3D, amafayili ensimbi akhishwa eduze kwe-spiral groove, futhi ikhwalithi yendawo yochungechunge iphezulu.

10~20° i-engeli ye-helix kampompi ingacubungula ukujula kwentambo ngaphansi noma okulingana no-2D;

28~40° i-engeli ye-helix kampompi ingacubungula ukujula kwentambo ngaphansi noma okulingana no-3D;

Ukuthepha kwe-engeli ye-helix engu-50° kungacubungula ukujula kwentambo ngaphansi noma okulingana no-3.5D (isimo esikhethekile sokusebenza esingu-4D).

Kwezinye izimo (izinto eziqinile, iphimbo elikhulu, njll.), ukuze uthole amandla angcono wethiphu yezinyo, umtshingo we-helical flute usetshenziselwa umshini ngokusebenzisa izimbobo.

3) Ukuthepha kwephuzu elivunguzayo: imvamisa isetshenziselwa kuphela ngokusebenzisa izimbobo, isilinganiso sobude bobubanzi singafinyelela ku-3D~3.5D, ama-chips ensimbi akhishelwa phansi, i-torque yokusika incane, futhi ikhwalithi yangaphezulu yentambo eyenziwe ngomshini iphezulu, eyaziwa nangokuthi i-edge angle tap noma i-apex tap.

Lapho usika, kuyadingeka ukuqinisekisa ukuthi zonke izingxenye zokusika zingena, ngaphandle kwalokho ukuphuka kwamazinyo kuzokwenzeka.

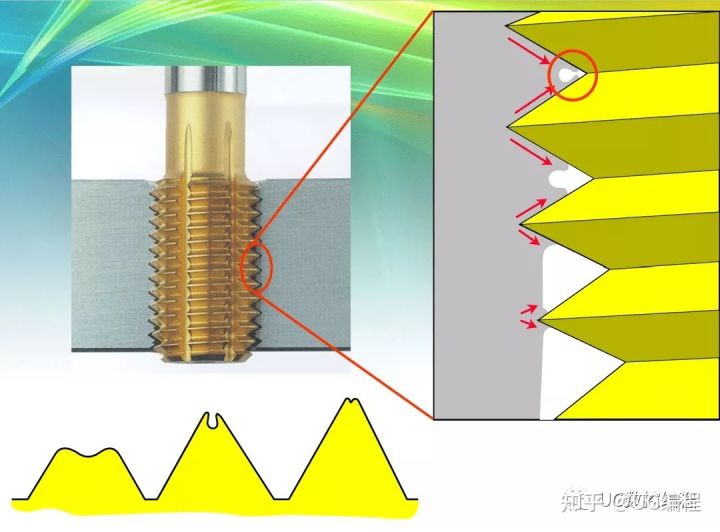

(2) Umpompi wokukhipha

Ingasetshenziselwa ukucutshungulwa ngokusebenzisa izimbobo nezimbobo eziyizimpumputhe, futhi ukwakheka kwezinyo kwenziwa yi-plastic deformation of the material, engasetshenziswa kuphela ukucubungula izinto zepulasitiki.

Izici zayo eziyinhloko:

1) Sebenzisa i-deformation yepulasitiki ye-workpiece ukucubungula intambo;

I-2) Indawo ye-cross-sectional kampompi inkulu, amandla aphezulu, futhi akulula ukuphuka;

I-3) Ijubane lokusika lingaba phezulu kunelo lokusika ompompi, futhi ukukhiqiza nakho kuyanda ngokufanele;

I-4) Ngenxa yenqubo ebandayo ye-extrusion, izakhiwo zemishini ye-thread surface ecutshungulwayo ziyathuthukiswa, ukugoqa kwendawo kuphezulu, futhi amandla entambo, ukumelana nokugqoka kanye nokumelana nokugqwala kuyathuthukiswa;

5) Imishini ye-chipless.

Amaphutha ayo yilezi:

1) ingasetshenziswa kuphela ukucubungula izinto zepulasitiki;

2) Izindleko zokukhiqiza ziphezulu.

Kunamafomu amabili esakhiwo:

1) Ompompi be-Extrusion abangenawo ama-grooves kawoyela asetshenziselwa kuphela umshini oqondile wemigodi eyimpumputhe;

2) Ompompi bokukhipha abanemifantu kawoyela bafaneleka kuzo zonke izimo zokusebenza, kodwa ngokuvamile ompompi abancane abanobubanzi abaklami imisele yamafutha ngenxa yobunzima bokukhiqiza.

(1) Ubukhulu

1) Ubude bubonke: Naka izimo ezithile zokusebenza ezidinga ukwelulwa okukhethekile

2) Ubude be-slot: dlula

3) I-Shank: Njengamanje, izindinganiso ezijwayelekile ze-shank yi-DIN (371/374/376), ANSI, JIS, ISO, njll. Lapho ukhetha, naka ubudlelwano obuhambisanayo ne-tapping shank.

(2) Ingxenye enomucu

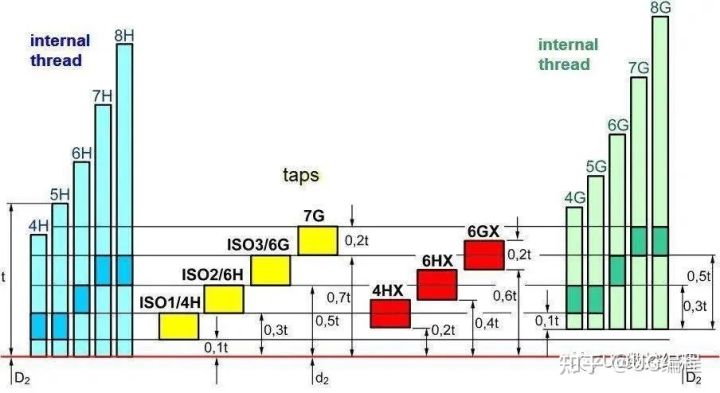

I-1) Ukunemba: Ikhethwa ngokwezinga elithile lentambo. Ileveli ye-ISO1/2/3 yochungechunge lwemethrikhi ilingana nezinga likazwelonke elijwayelekile le-H1/2/3, kodwa kuyadingeka ukunaka izindinganiso zokulawula zangaphakathi zomenzi.

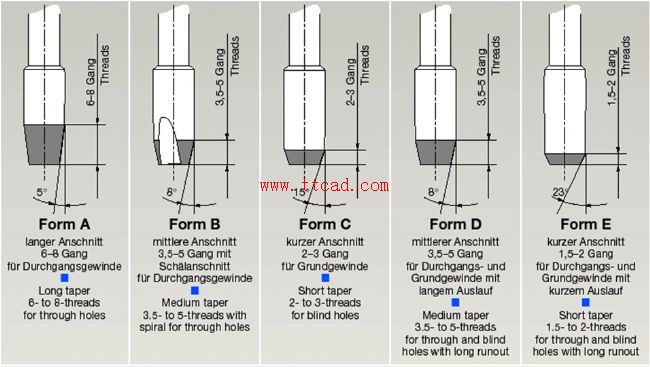

2) Umpompi wokusika: Ingxenye yokusika kampompi yakha ingxenye yephethini engashintshi. Ngokuvamile, uma umpompi osikayo umude, impilo kampompi iba ngcono.

3) Amazinyo okulungisa: Idlala indima yokusiza nokulungiswa, ikakhulukazi esimweni esingazinzile sesistimu yokuthinta, amazinyo amaningi okulungisa, kukhulu ukumelana nokuthepha.

(3) Imitshingo ye-chip

1. Uhlobo lwe-Groove: Luthinta ukwakheka nokukhishwa kwamafayili ensimbi, ngokuvamile okuyimfihlo yangaphakathi yomkhiqizi ngamunye.

2. I-rake angle kanye ne-engeli yokusiza: lapho umpompi unyuswa, umpompi uba bukhali, okunganciphisa kakhulu ukumelana nokusika, kodwa amandla nokuzinza kwethiphu lezinyo kuncipha, futhi i-engeli yokusiza i-engeli yokusiza.

3. Inombolo yama-grooves: inani lama-grooves liyakhula futhi inani lemiphetho yokusika liyanda, elingathuthukisa ngokuphumelelayo impilo yompompi; kodwa izocindezela isikhala sokususa i-chip, engafanele ukususwa kwe-chip.

03 Thepha impahla kanye nenamathela

(1) Izinto zikampompi

1) Insimbi yamathuluzi: Isetshenziswa kakhulu ompompi be-incisor ngesandla, okungajwayelekile okwamanje.

2) Insimbi enejubane eliphezulu engena-Cobalt: Okwamanje, isetshenziswa kabanzi njengezinto zompompi, njenge-M2 (W6Mo5Cr4V2, 6542), M3, njll., kanye nekhodi yokumaka i-HSS.

3) Insimbi enejubane eliphezulu i-cobalt: okwamanje isetshenziswa kabanzi njengezinto zompompi, njenge-M35, M42, njll., ikhodi yokumaka i-HSS-E.

4) Insimbi ye-powder enesivinini esikhulu: Isetshenziswa njengento esebenza kakhulu kampompi, ukusebenza kuba ngcono kakhulu uma kuqhathaniswa nalokhu okubili okungenhla. Izindlela zokuqamba zomkhiqizi ngamunye nazo zihlukile, futhi ikhodi yokumaka ithi HSS-E-PM.

5) Izinto ze-carbide zikasimende: imvamisa zisebenzisa izinhlayiya ezinhle kakhulu kanye namamaki amahle okuqina, asetshenziswa kakhulu ukwenza ompompi bomtshingo oqondile ukucubungula izinto ezimfishane ze-chip, njengensimbi empunga, i-silicon aluminium ephezulu, njll.

Ompompi bancike kakhulu ezintweni ezisetshenziswayo, futhi ukukhethwa kwezinto ezinhle kungathuthukisa kakhulu imingcele yesakhiwo sompompi, kubenze bafanelekele ukusebenza kahle okuphezulu nezimo zokusebenza ezinzima, futhi ngesikhathi esifanayo babe nempilo yesevisi ephakeme. Njengamanje, abakhiqizi abakhulu bampompi banamafekthri abo wezinto ezibonakalayo noma amafomula wezinto ezibonakalayo. Ngesikhathi esifanayo, ngenxa yezinkinga zezinsiza ze-cobalt namanani, izinsimbi ezintsha ezingenayo i-cobalt high-performance high-speed steels nazo ziphumile.

(2) Ukumboza umpompi

1) I-steam oxidation: Impompi ifakwa kumhwamuko wamanzi onezinga lokushisa eliphezulu ukuze kwakhe ifilimu ye-oxide ngaphezulu, ene-adsorption enhle esipholisayo, inganciphisa ukungqubuzana, futhi ivimbele umpompi nezinto ezizosikwa. Ifanele ukwenziwa kwensimbi emnene.

I-2) Ukwelashwa kwe-Nitriding: Ingaphezulu likampompi lifakwe i-nitrided ukuze kwakhiwe ungqimba oluqinile, olulungele ukukhanda insimbi ecijile, i-aluminium ekhonjiwe kanye nezinye izinto ezinokuguga okukhulu kwamathuluzi.

3) I-Steam + Nitriding: Hlanganisa izinzuzo zalokhu okubili okungenhla.

4) I-TiN: i-golden yellow coating, enobulukhuni obuhle bokunamathela kanye nokuthambisa, nokunamathela okuhle kokunamathela, okulungele ukucubungula izinto eziningi.

5) I-TiCN: i-blue-grey enamathela ngobulukhuni obungaba ngu-3000HV kanye nokumelana nokushisa okungu-400°C.

I-6) I-TiN+TiCN: i-coat ephuzi emnyama, enokuqina okuhle kakhulu kokunamathela kanye nokuthambisa, kulungele ukucubungula izinto eziningi.

I-7) I-TiAlN: i-blue-gray coating, ubulukhuni be-3300HV, ukumelana nokushisa kufika ku-900 ° C, ingasetshenziselwa umshini wejubane eliphezulu.

8) I-CrN: i-silver-gray coating, ukusebenza okuhle kakhulu kokugcoba, okusetshenziselwa ikakhulukazi ukucubungula izinsimbi ezingenayo ayoni.

Umthelela wokumbozwa kompompi ekusebenzeni kompompi ubonakala kakhulu, kodwa okwamanje, abakhiqizi abaningi nabakhiqizi bokugcoba babambisana ukuze bafunde ukugqoka okukhethekile.

04 Izinto Ezithinta Ukuthepha

(1) Imishini yokushaya

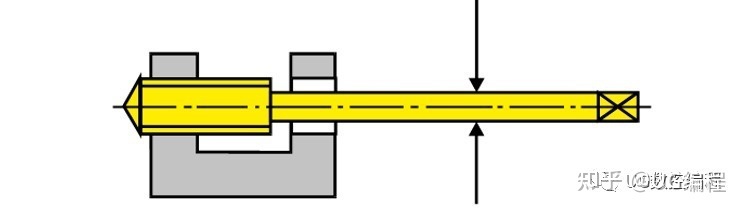

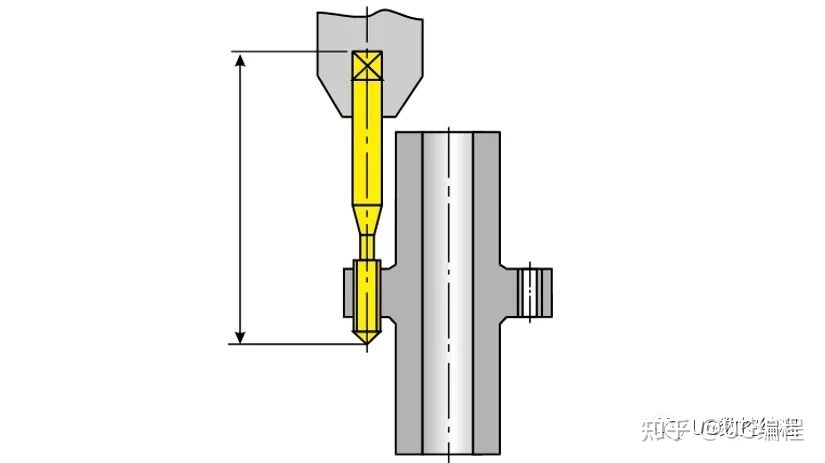

I-1) Ithuluzi lomshini: Ingahlukaniswa ngezindlela zokucubungula eziqondile nezivundlile. Ngokuthepha, ukucubungula okuqondile kungcono kunokucubungula okuvundlile. Uma ukupholisa kwangaphandle kwenziwa ngokucubungula okuvundlile, kuyadingeka ukucabangela ukuthi ukupholisa kwanele yini.

2) Isibambi sethuluzi lokuthepha: Kunconywa ukusebenzisa isibambi sethuluzi lokuthepha elikhethekile ukuze uthephe. Ithuluzi lomshini liqinile futhi lizinzile, futhi isibambi sethuluzi lokuthepha esivumelanayo siyakhethwa. Ngokuphambene, isibambi sethuluzi lokuthepha esiguquguqukayo esinesinxephezelo se-axial/radial kufanele sisetshenziswe kakhulu ngangokunokwenzeka. . Ngaphandle kompompi abancane bobubanzi (

(2) Izinto zokusebenza

1) Impahla nobulukhuni bengcezu yokusebenza: ubulukhuni bempahla yokusebenza kufanele bufane, futhi ngokuvamile akunconyiwe ukusebenzisa ompompi ukucubungula izinto zokusebenza ezedlula i-HRC42.

2) Ukushaya imbobo engezansi: isakhiwo sembobo engezansi, khetha i-drill bit efanelekile; ukunemba kosayizi wembobo engezansi; imbobo ephansi izinga odongeni.

(3) Amapharamitha wokucubungula

I-1) Isivinini sokujikeleza: Isisekelo sejubane elinikeziwe lokuzungeza uhlobo lukampompi, impahla, impahla okufanele icutshungulwe kanye nobulukhuni, ikhwalithi yemishini yokuthepha, njll.

Imvamisa ekhethwa ngokuya ngamapharamitha anikezwe umenzi kampompi, isivinini kufanele sehliswe ngaphansi kwalezi zimo ezilandelayo:

- ukuqina komshini ompofu; ukuphuma kompompi omkhulu; ukupholisa okunganele;

- izinto ezingalingani noma ubulukhuni endaweni yokudonsa, njengamajoyinti e-solder;

- impompi inwetshiwe, noma kusetshenziswa induku yokunweba;

- I-Recumbent plus, ukupholisa ngaphandle;

- Ukusebenza ngesandla, okufana nokubhoboza ibhentshi, ukubhola nge-radial, njll.;

2) Okuphakelayo: ukuthepha okuqinile, okuphakelayo = 1 iphimbo/uguquko.

Endabeni yokuthepha okuguquguqukayo kanye nokuhlukahluka okwanele kwesinxephezelo se-shank:

Okuphakelayo = (0.95-0.98) ama-pitches/rev.

05 Amathiphu okukhetha ompompi

(1) Ukubekezelela ompompi bamabanga ahlukene anembayo

Isisekelo sokukhetha: ibanga lokunemba likampompi alikwazi ukukhethwa futhi linqunywe kuphela ngokuya ngebanga lokunemba kwentambo eyenziwayo

1) Impahla nobulukhuni be-workpiece okufanele icutshungulwe;

2) Izinto zokuthepha (njengezimo zethuluzi lomshini, izibambi zamathuluzi okubamba, izindandatho zokupholisa, njll.);

3) Ukunemba kanye nephutha lokukhiqiza likampompi ngokwawo.

Isibonelo, lapho ucubungula izintambo ze-6H, lapho ucubungula izingxenye zensimbi, ompompi bokunemba okungu-6H bangasetshenziswa; lapho ucubungula insimbi empunga, ngoba ububanzi obumaphakathi bompompi buguga ngokushesha futhi ukunwetshwa kwezimbobo zesikulufa kuncane, kungcono ukusebenzisa ompompi abanemba okungu-6HX. Thepha, impilo izoba ngcono.

Inothi ngokunemba kompompi baseJapan:

1) I-OSG yompompi wokusika isebenzisa isistimu yokunemba ye-OH, ehlukile kunezinga le-ISO. Isistimu yokunemba ye-OH iphoqa ububanzi bayo yonke ibhendi yokubekezelelana ukuthi iqale kusukela kumkhawulo ophansi kakhulu, futhi yonke i-0.02mm isetshenziswa njengebanga lokunemba, eliqanjwe ngokuthi OH1, OH2, OH3, njll.;

2) I-OSG yompompi we-extrusion isebenzisa isistimu yokunemba ye-RH. Isistimu yokunemba ye-RH iphoqa ububanzi bayo yonke ibhendi yokubekezelela ukuthi iqale kusukela kumkhawulo ophansi, futhi i-0.0127mm ngayinye isetshenziswa njengezinga lokunemba, eliqanjwe ngokuthi RH1, RH2, RH3, njll.

Ngakho-ke, uma usebenzisa ompompi bokunemba kwe-ISO ukuze umiselele ompompi be-OH abanembayo, akunakucatshangwa nje ukuthi i-6H icishe ilingane nebanga le-OH3 noma le-OH4. Idinga ukunqunywa ukuguqulwa, noma ngokuya ngesimo sangempela sekhasimende.

(2) Ubukhulu bompompi

1) Ezisetshenziswa kakhulu yi-DIN, ANSI, ISO, JIS, njll.;

2) Kuvunyelwe ukukhetha ubude obufanele obuphelele, ubude be-blade kanye nosayizi we-shank ngokusho kwezidingo ezahlukene zokucubungula zamakhasimende noma izimo ezikhona;

3) Ukuphazanyiswa ngesikhathi sokucubungula;

(3) 6 izici eziyisisekelo zokukhetha kampompi

1) Uhlobo lokucubungula intambo, imethrikhi, intshi, iMelika, njll.;

2) Uhlobo lwembobo engezansi enentambo, ngembobo noma imbobo eyimpumputhe;

I-3) Impahla nobulukhuni be-workpiece okufanele icutshungulwe;

4) Ukujula kwentambo ephelele ye-workpiece kanye nokujula komgodi ongezansi;

5) Ukunemba okudingekayo kwentambo ye-workpiece;

6) Izinga lomumo kampompi

Isikhathi sokuthumela: Jul-20-2022