1, Inqubo yokukhetha yabasiki bokugaya ngokuvamile ibheka izici ezilandelayo ongakhetha kuzo:

(1) Ingxenye yomumo (kucatshangelwa iphrofayili yokucubungula): Iphrofayili yokucubungula ngokuvamile ingaba isicaba, ijule, ingaphakathi, intambo, njll. Amathuluzi asetshenziselwa amaphrofayili wokucubungula ahlukile. Isibonelo, i-fillet milling cutter ingakwazi ukugaya izindawo ezi-convex, kodwa hhayi izindawo ze-Milling concave.

(2) Material: Cabangela machinability yayo, chip forming, ubulukhuni kanye izakhi alloying. Abakhiqizi bamathuluzi ngokuvamile bahlukanisa izinto zokwakha zibe insimbi, insimbi engagqwali, insimbi ekhonjiwe, izinsimbi ezingenayo insimbi, ama-alloy amakhulu, ama-titanium alloys nezinto eziqinile.

(3) Izimo zomshini: Izimo zomshini zihlanganisa ukuzinza kwesistimu ye-workpiece yomshini wokulungisa ithuluzi, isimo sokubopha umnikazi wamathuluzi nokunye.

(4) Ukuzinza kwesistimu yomshini wokulungisa ithuluzi lomshini: Lokhu kudinga ukuqonda amandla atholakalayo ethuluzi lomshini, uhlobo lokuphotha nokucaciswa, ubudala bethuluzi lomshini, njll., kanye nokulenga okude kwesibambi samathuluzi kanye Nesimo saso sokuphuma kwe-axial/radial.

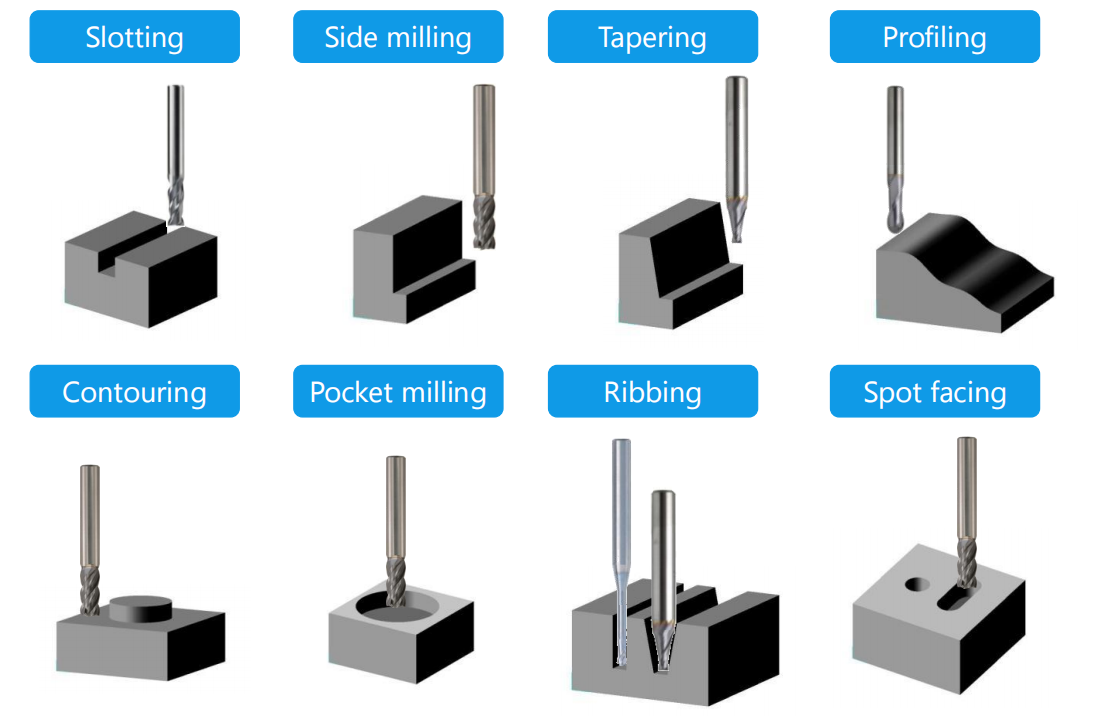

(4) Isigaba sokucubungula kanye nesigaba esingaphansi: Lokhu kuhlanganisa ukugaya ihlombe, ukugaya indiza, ukugaya iphrofayili, njll., okudingeka kuhlanganiswe nezici zethuluzi lokukhethwa kwamathuluzi.

2. Ukukhethwa kwe-engeli yejometri yomsiki wokugaya

(1) Ukukhethwa kwe-engeli yangaphambili. I-rake angle ye-milling cutter kufanele inqunywe ngokuya ngempahla yethuluzi kanye nendawo yokusebenza. Kuvame ukuba nemithelela ekugayeni, ngakho-ke kuyadingeka ukuqinisekisa ukuthi unqenqema lokusika lunamandla aphezulu. Ngokuvamile, i-engeli yerakhi yesisiki sokugaya incane kune-engeli yokusika yethuluzi lokujika; insimbi enesivinini esikhulu inkulu kunethuluzi le-carbide elisimende; ngaphezu kwalokho, lapho ukugaya izinto zepulasitiki, ngenxa ye-deformation enkulu yokusika, kufanele kusetshenziswe i-rake angle enkulu; lapho milling brittle materials , I-engeli ye-rake kufanele ibe yincane; lapho ucubungula izinto ezinamandla amakhulu nobulukhuni, i-rake angle engalungile ingasetshenziswa.

(2) Ukukhetha ukuthambekela kwe-blade. I-engeli ye-helix engu-β yendingilizi yangaphandle yesigayo sokuphela kanye ne-cylindrical milling cutter i-blade inclination λ s. Lokhu kwenza amazinyo okusika akwazi ukusikeka kancane kancane aphinde aphume endaweni yokusebenzela, okwenza ukuba ukugaya kube bushelelezi. Ukwengeza u-β kungakhuphula i-engeli ye-rake yangempela, kucije unqenqema lokusika, futhi kwenze ama-chips akhiphe kalula. Kubasiki bokugaya abanobubanzi obuncane bokugaya, ukukhulisa i-engeli ye-helix engu-β akubalulekanga kangako, ngakho-ke u-β=0 noma inani elincane ngokuvamile liyathathwa.

(3)Ukukhethwa kwe-engeli enkulu yokuchezuka kanye ne-engeli yesibili yokuchezuka. Umthelela we-engeli yokungena ye-face milling cutter kanye nomthelela wayo enqubweni yokugaya kuyafana naleyo ye-engeli yokungena yethuluzi lokujika ekujikeni. Ama-engeli okungena asetshenziswa kakhulu ngu-45°, 60°, 75°, no-90°. Ukuqina kwesistimu yenqubo kuhle, futhi inani elincane liyasetshenziswa; uma kungenjalo, inani elikhulu liyasetshenziswa, futhi ukukhethwa kwe-engeli yokungena kuboniswa kuThebula 4-3. I-engeli yesibili yokuchezuka ivamise ukuba ngu-5°~10°. I-cylindrical milling cutter inomkhawulo oyinhloko wokusika kuphela futhi ayikho i-edge yesibili yokusika, ngakho-ke ayikho i-engeli yesibili yokuphambuka, futhi i-engeli yokungena ingu-90 °.

Isikhathi sokuthumela: Aug-24-2021