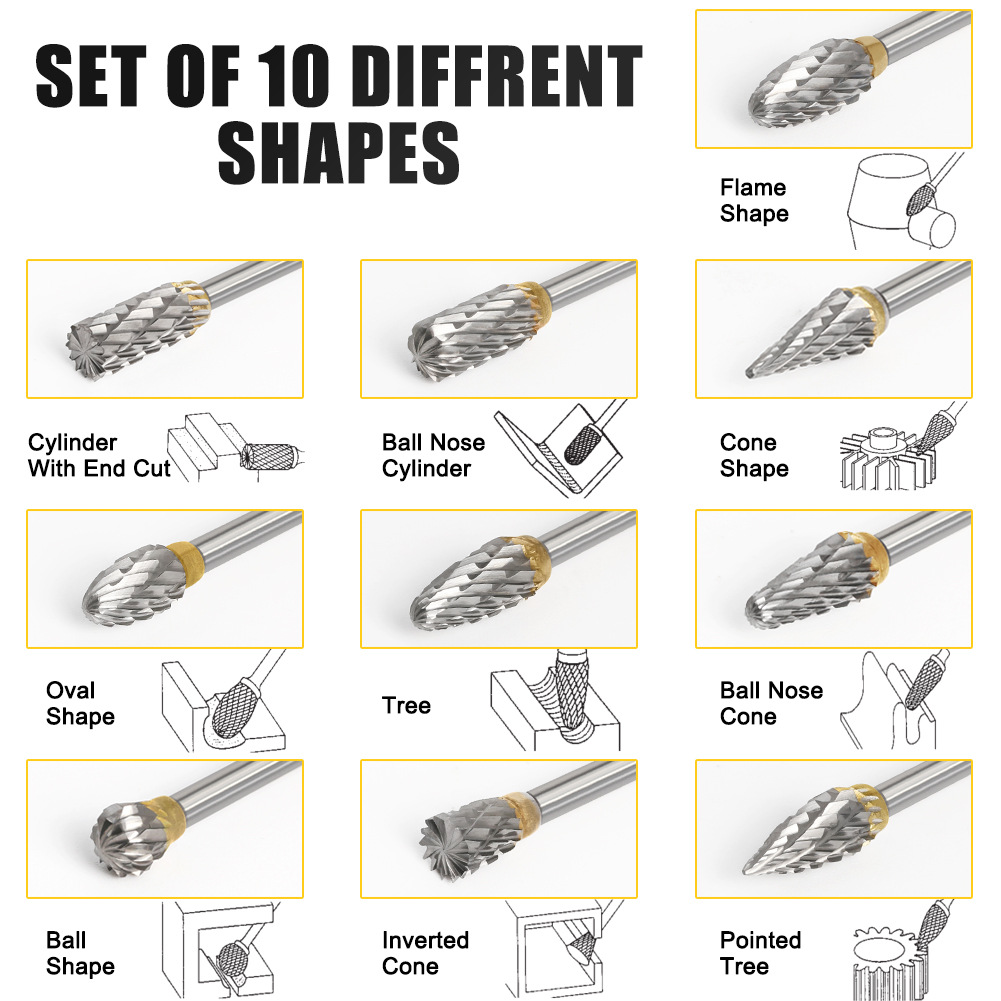

Umumo we-cross-sectional of theukugaya insimbi ye-tungstenama-burrskufanele kukhethwe ngokuvumelana nokuma kwezingxenye okufanele zifakwe, ukuze izimo zezingxenye ezimbili zingashintshwa. Uma ufaka i-arc surface yangaphakathi, khetha i-semi-circular noma i-carbide bur eyindilinga; lapho ufaka indawo yangaphakathi yekhona, khetha ifayela elingunxantathu; lapho ufaka indawo engaphakathi ye-engeli yesokudla, ungakhetha ifayela eliyisicaba noma isikwele sokubaza ibhithi. Uma ukhetha indawo engaphakathi ye-engeli engakwesokudla yefayela eliyisicaba, naka ukwenza indawo encane yefayela elingenamazinyo isondele ohlangothini lwe-engeli yesokudla yangaphakathi ukuze ugweme ukulimala endaweni ye-engeli engakwesokudla.

Ubukhulu bamazinyo anqunywe kufanele bukhethwe ngokuhambisana nobukhulu besabelo, ukunemba kwemishini kanye nezakhiwo ezibonakalayo ze-workpiece. Amafayela anamazinyo aqinile afanele izinto zokusebenza ezinezibonelelo ezinkulu zomshini, ukunemba okuphansi kwe-dimensional, ukubekezelela okukhulu kwejometri, amanani amakhulu ama-surface roughness, nezinto ezithambile; ngokuphambene nalokho, kufanele kusetshenziswe amafayela anamazinyo amahle. Uma usebenzisa, kufanele kukhethwe ngokuvumelana nemvume yomshini, ukunemba kwe-dimensional kanye nobukhulu obuphezulu obufunwa yi-workpiece.

Ubukhulu kanye nokucaciswa kwekhanda lokugaya insimbi ye-tungsten kufanele kukhethwe ngokuhambisana nobukhulu kanye nemvume yomshini we-workpiece okufanele icutshungulwe. Uma usayizi wokucubungula mkhulu futhi imvume inkulu, ifayela elinosayizi omkhulu kufanele likhethwe. Ukuma kwezinyo kwefayela lekhanda lokugaya insimbi ye-tungsten kufanele kukhethwe ngokuvumelana nemvelo yezinto okufanele zifakwe. Lapho ufaka izinto ezithambile ezifana ne-aluminium, ithusi, nensimbi ye-carbon ephansi, kungcono ukusebenzisa ifayela lezinyo elilodwa.

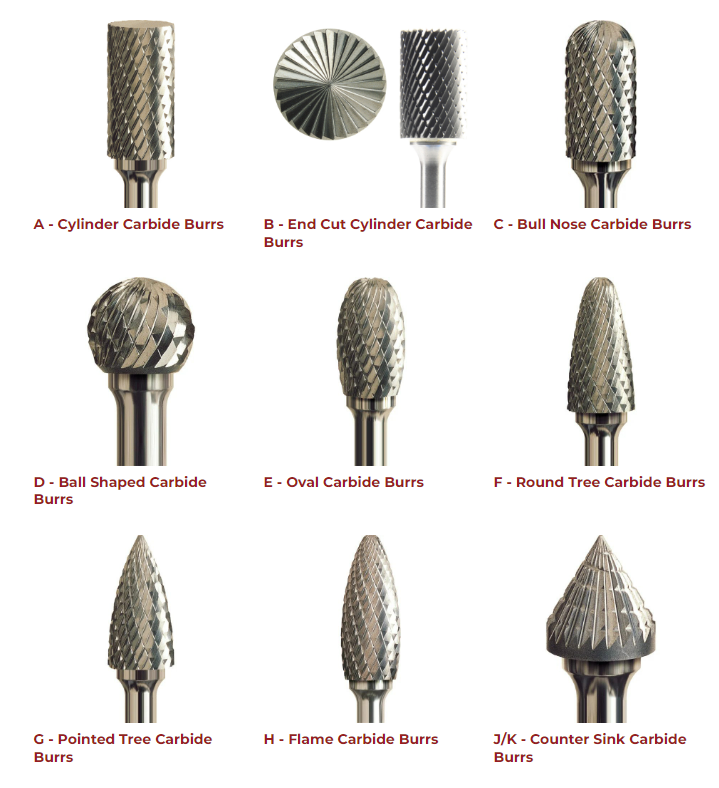

Izinzuzo ze-Carbide Tip Rotary Burr:

1. Ingakwazi ukucubungula izinsimbi ezifana ne-cast iron, cast steel, carbon steel, i-alloy steel, insimbi engagqwali, ithusi ne-aluminium, kanye nezingezona izinsimbi njengemabula, i-jade nethambo.

2. Ingakwazi ukufaka isibambo esikhundleni sesondo elincane lokugaya, akukho ukungcola kothuli kanye nokusebenza kahle kokukhiqiza. Ukusebenza kahle kokucubungula kuphakeme izikhathi eziningi kunaleyo yamafayela okwenziwa ngesandla, futhi cishe izikhathi eziyishumi ziphakeme kunalezo zamasondo amancane okugaya anezibambo.

3. Ikhwalithi enhle yokucubungula nokuqeda okuphezulu. Ingakwazi ukucubungula izimbotshana zesikhunta ezinokwakheka okuhlukahlukene okunembe kakhulu, futhi ukuqina kwayo kuphakeme ngokuphindwe kashumi kunamathuluzi ensimbi anesivinini esikhulu futhi ephakeme ngokuphindwe izikhathi ezingaphezu kuka-200 kunaleyo yamasondo amancane okugaya. Kulula ukuyiqonda, kulula ukuyisebenzisa, iphephile futhi inokwethenjelwa.

Ukuze ukwandise impilo yenkonzo yekhanda lokugaya insimbi ye-tungsten, le mithetho elandelayo kufanele igcinwe:

1. Akuvunyelwe ukusebenzisa amafayela amasha e-carbide rotary ukuchoboza izinsimbi ezinzima;

2. Akuvunyelwe ukusebenzisa ikhanda lokugaya insimbi ye-tungsten ukuze ugcwalise izinto eziqinile, ama-forging kanye nama-castings ngesikhumba esiqinile noma isihlabathi esinamathelayo. Kufanele zigaywe emshinini wokugaya ngaphambi kokuba zigcwaliswe ngefayela elinephuzu elinguhhafu;

3. Sebenzisa uhlangothi olulodwa lwe-tungsten carbide rotary burrs kuqala, bese usebenzisa olunye uhlangothi ngemva kokuba ingaphezulu liba buthuntu. Ngaso sonke isikhathi sebenzisa ibhulashi locingo ukuze ususe udoti lapho usikwa, futhi ukusikwa akufanele kudlulelane noma kunqwabelene namanye amathuluzi.

Uma ufuna ukuthenga ama-carbide rotary burrs, sicela uvakashele iwebhusayithi yethu:https://www.mskcnctools.com/3mm-shank-carbide-tip-rotary-burr-cut-carving-bit-product/

Noma thintana noMolly WhatsApp:+8613602071763 ukuze uthole uhlu lwamanani.

Isikhathi sokuthumela: Oct-19-2022