Namuhla, ngizokwabelana ngendlela yokukhetha i-drill bit ngokusebenzisa izimo ezintathu eziyisisekelo ze-i-drill bit, okuyizinto: impahla, ukugqoka kanye nezici zejometri.

1

Indlela yokukhetha impahla ye-drill

Izinto ezisetshenziswayo zingahlukaniswa cishe zibe izinhlobo ezintathu: insimbi enesivinini esikhulu, insimbi ene-cobalt enesivinini esikhulu kanye ne-carbide eqinile.

I-Speed Speed Steel (HSS):

Insimbi enesivinini esikhulu njengamanje iyithuluzi lokusika elisetshenziswa kakhulu futhi elishibhe kakhulu. I-drill bit of high-speed steel ingasetshenziswa hhayi kuphela kuma-drill kagesi esandleni, kodwa nasezindaweni ezinokuzinza okungcono njengemishini yokubhoboza. Esinye isizathu sokuphila isikhathi eside kwensimbi enesivinini esikhulu kungenzeka ukuthi ithuluzi elenziwe ngensimbi enesivinini esikhulu lingagaywa ngokuphindaphindiwe. Ngenxa yentengo ephansi, ayisetshenziselwa kuphela ukugaya zibe izingcezu zokubhoboza, kodwa futhi isetshenziswa kabanzi ekuphenduleni amathuluzi.

I-Cobalt High Speed Steel (HSSCO):

Insimbi ene-cobalt enejubane eliphezulu inobunzima obungcono nobulukhuni obubomvu kunensimbi enesivinini esikhulu, futhi ukwanda kokuqina nakho kuthuthukisa ukumelana kwayo nokugqoka, kodwa ngesikhathi esifanayo kudela ingxenye yokuqina kwayo. Okufanayo nensimbi enesivinini esikhulu: zingasetshenziswa ukuthuthukisa inani lezikhathi ngokugaya.

I-Carbide (i-CARBIDE):

I-carbide enosimende iyinhlanganisela yezinto ezenziwe ngensimbi. Phakathi kwazo, i-tungsten carbide isetshenziswa njenge-matrix, kanti ezinye izinto zezinye izinto zisetshenziswa njengesibophezelo ukuze sifakwe uchungechunge lwezinqubo eziyinkimbinkimbi ezifana nokucindezela kwe-isostatic okushisayo. Uma kuqhathaniswa nensimbi enesivinini esikhulu mayelana nobunzima, ubulukhuni obomvu, ukumelana nokugqoka, njll., kukhona ukuthuthukiswa okukhulu, kodwa izindleko zamathuluzi e-carbide enosimende nazo zibiza kakhulu kunensimbi enesivinini esikhulu. I-Carbide inezinzuzo eziningi kunezinto zamathuluzi zangaphambilini ngokwempilo yamathuluzi nesivinini sokucubungula. Ekugayweni okuphindaphindiwe kwamathuluzi, amathuluzi okugaya adingekayo ayadingeka.

2

Indlela yokukhetha i-drill coating

Izembatho zingahlukaniswa cishe zibe yizinhlobo ezinhlanu ezilandelayo ngokuya kobubanzi bokusetshenziswa.

Okungagqotshiwe:

Imimese engaboshiwe iyona eshibhe kakhulu futhi ngokuvamile isetshenziselwa umshini izinto ezithambile ezifana nama-alloys e-aluminium nensimbi ethambile.

I-Black oxide coating:

Izembatho ezine-oxidized zinganikeza ukuthambisa okungcono kunamathuluzi angagcotshiwe, futhi futhi zingcono ngokuya nge-oxidation nokumelana nokushisa, futhi zingandisa impilo yesevisi ngaphezu kuka-50%.

Ukufakwa kwe-Titanium nitride:

I-Titanium nitride iyinto evamile yokuhlanganisa futhi ayifanele ukucubungula izinto ezinobunzima obuphezulu kanye nezinga lokushisa eliphezulu lokucubungula.

I-Titanium carbonitride coating:

I-Titanium carbonitride ithuthukiswa isuka ku-titanium nitride futhi inezinga lokushisa eliphezulu eliphakeme nokumelana nokugqoka, ngokuvamile okunsomi noma okuluhlaza okwesibhakabhaka. Isetshenziswa ngomshini izinsimbi zokusansimbi endaweni yokusebenzela yakwa-Haas.

I-Aluminium Nitride Titanium Coating:

I-Aluminium titanium nitride imelana kakhulu namazinga okushisa aphezulu kunazo zonke izimbotshana ezingenhla, ngakho-ke ingasetshenziswa ezindaweni zokusika eziphakeme. Ngokwesibonelo, ukucubungula superalloys. Iphinde ifanele ukucutshungulwa kwensimbi nensimbi engagqwali, kodwa ngenxa yezakhi eziqukethe i-aluminium, ukusabela kwamakhemikhali kuzokwenzeka lapho kucutshungulwa i-aluminium, ngakho gwema ukucubungula izinto eziqukethe i-aluminium.

3

Drill bit geometry

Izici zeJomethri zingahlukaniswa zibe izingxenye ezi-3 ezilandelayo:

Ubude

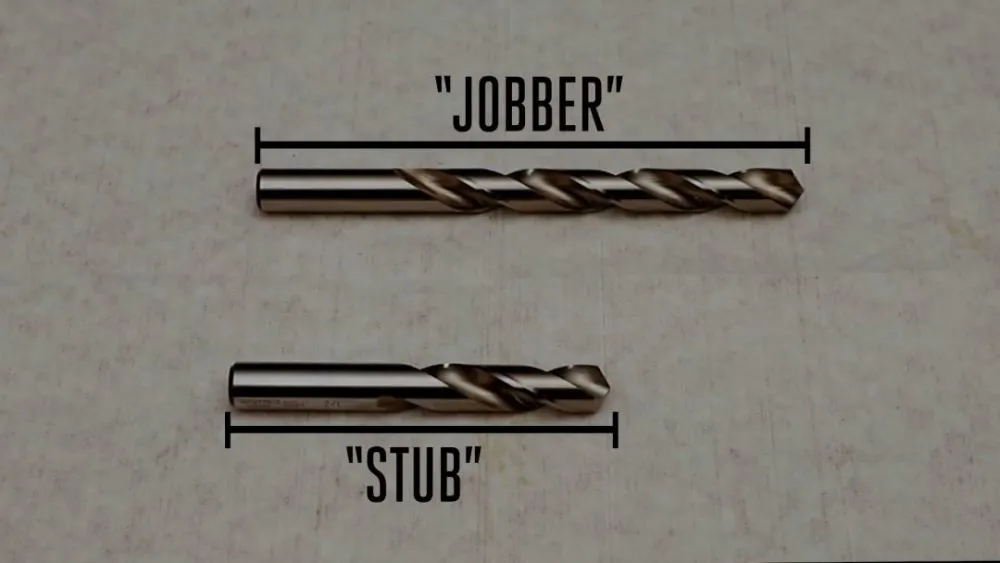

Isilinganiso sobude kuya kobubanzi sibizwa ngokuthi i-double diameter, futhi encane ububanzi obuphindwe kabili, ngcono ukuqina. Ukukhetha i-drill enobude bonqenqema ukuze ikhiphe i-chip kanye nobude obufushane obuyi-overhang kungathuthukisa ukuqina ngesikhathi somshini, ngaleyo ndlela kwandise impilo yesevisi yethuluzi. Ubude be-blade obanele kungenzeka bulimaze i-drill.

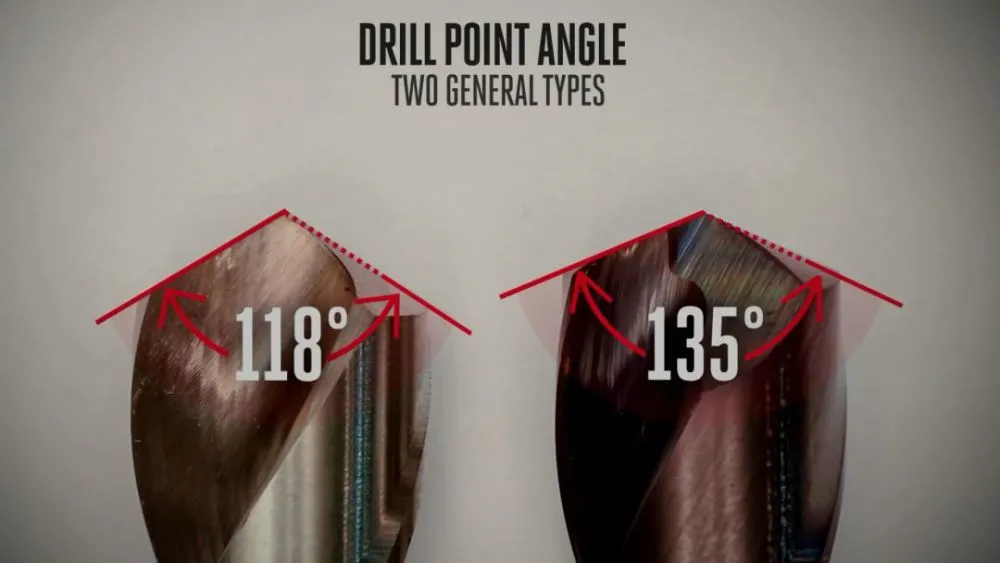

I-engeli yethiphu yokubhoboza

I-engeli yethiphu yokubhoboza engu-118° cishe iyona evame kakhulu ekwenzeni imishini futhi ivamise ukusetshenziselwa izinsimbi ezithambile njengensimbi emaphakathi ne-aluminium. Idizayini yale engeli ngokuvamile ayizimisi yona, okusho ukuthi akunakugwenywa umshini womgodi omaphakathi kuqala. I-engeli yethiphu yokubhoboza engu-135° ivamise ukuba nomsebenzi wokuzimisa wena. Njengoba asikho isidingo somshini womgodi wokugxilisa, lokhu kuzokwenza kungadingeki ukubhoboza imbobo emaphakathi ngokwehlukana, ngaleyo ndlela ulondoloze isikhathi esiningi.

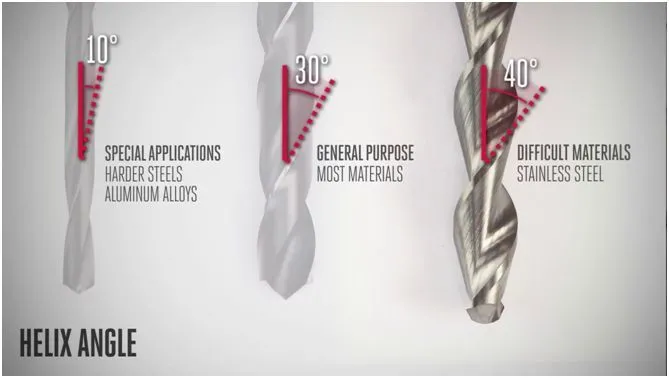

I-angle ye-Helix

I-engeli ye-helix engu-30 ° iyisinqumo esihle ezintweni eziningi. Kodwa ezindaweni ezidinga ukukhishwa okungcono kwe-chip kanye nonqenqema lokusika oluqinile, umshini wokubhoboza one-engeli ye-helix encane ingakhethwa. Ngezinto ezisebenza kanzima emshinini njengensimbi engagqwali, idizayini ene-engeli ye-helix enkulu ingakhethwa ukuze idlulise i-torque.

Isikhathi sokuthumela: Jun-02-2022