Ukufakwa Kwensimbi Yesivinini Esikhulu: Amathuluzi Okusika Ahlukahlukene Wokunemba kanye Nempumelelo

Uma kukhulunywa ngokusika izinto eziqinile ngokunemba nokusebenza kahle, akukho okudlula i-High Speed Steel (HSS) blade. Lawa ma-blades asetshenziswa kakhulu ezimbonini ezahlukahlukene ngenxa yokusebenza kwawo okuphakeme kakhulu nokuqina. Kulokhu okuthunyelwe kwebhulogi, sizohlola izakhiwo kanye nokusetshenziswa kokufakwa kwe-HSS, okuhlanganisa nokufaka okudumile kwe-HSS nokusika.Amathuluzi we-HSS lathe.

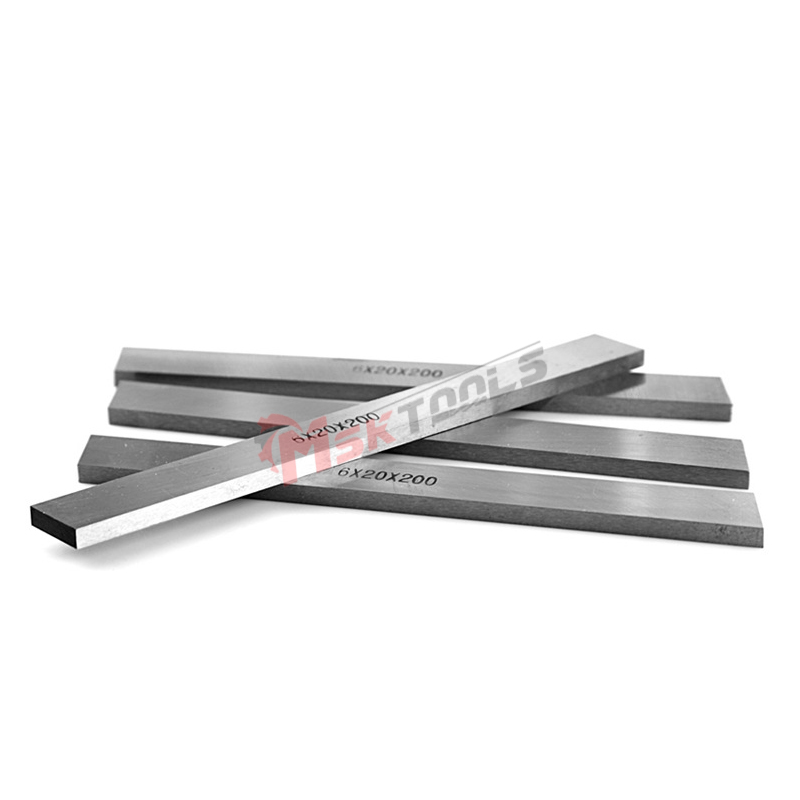

Izindwani zensimbi ezinesivinini esikhuluzaziwa ngokukwazi kwazo ukumelana namazinga okushisa aphezulu akhiqizwa ngesikhathi sokusika, okuzenza zilungele izinhlelo zokusebenza ezinzima. Ukusebenzisa insimbi enesivinini esikhulu njengento eyinhloko kuqinisekisa ukuthi i-blade igcina ubulukhuni nobukhali bayo ngisho namazinga okushisa aphezulu. Lokhu kubangela isivinini sokusika esisheshayo, ukwanda kokukhiqiza nokuphila kwamathuluzi okude.

Enye yezinhlelo ezivame kakhulu zokufakwa kwe-HSS ukusika insimbi. Noma ngabe ukulolonga, ukuhlukanisa, noma ukususa impahla eningi, izinsimbi zensimbi ezinesivinini esikhulu zihamba phambili ekuletheni ukusikeka okuhlanzekile, okunembayo. Ngokuqondene,high-speed steel ukusika izindwaniasetshenziswa kakhulu ezimbonini ezifana nezezimoto, i-aerospace kanye nezokukhiqiza. Ikhono layo lokusika ngokushesha ezinhlobonhlobo zezinsimbi, okuhlanganisa insimbi, i-aluminium nethusi, lenza ithuluzi lokuzikhethela kochwepheshe abaningi.

Elinye ithuluzi lensimbi elinesivinini esikhulu elaziwayo embonini yensimbi yithuluzi lensimbi elinesivinini esikhulu. Imisebenzi ye-lathe idinga amathuluzi okusika angakwazi ukumelana nesivinini esiphezulu sokujikeleza nokusetshenziswa okuqhubekayo. Amathuluzi ensimbi anesivinini esiphezulu aklanyelwe ukuhlangabezana nalezi zidingo, anikeze ukusebenza okuphakeme nokunemba. Kusukela ekubhekaneni nasekuxhumeni kuya ekukhanyeni nasekuhambeni, lawa mathuluzi aletha imiphumela engaguquki ezintweni ezihlukahlukene ezihlanganisa insimbi engagqwali, insimbi ewugqinsi kanye ne-titanium.

Nakuba ukufakwa kwe-HSS kuvame ukuhlotshaniswa nokusika insimbi, ukuguquguquka kwakho kudlulela nakwezinye izinto. Izindwani zensimbi ezinesivinini esikhulu zisebenza ngokulinganayo ekugawuleni izinkuni, ipulasitiki, ngisho nezinye izinto eziyinhlanganisela. Ngakho-ke, bathola isicelo ekubazeni, kwezokwakha nakwezinye izimboni ezidinga ukusika okunembile kwezinto ezahlukene.

Ukunakekelwa okufanele nokuphatha kubalulekile ukuze kuqinisekiswe imiphumela engcono kakhulu evela kuma-HSS blades. Ukuhlolwa njalo nokucija i-blade kuyadingeka ukuze kugcinwe ukusebenza kwayo kokusika. Ukwengeza, ukusebenzisa imingcele yokusika efanele njengejubane, izinga lokudla kanye nokugcoba kungathuthukisa kakhulu impilo yamathuluzi nokukhiqiza.

Sengiphetha, ifaka i-HSS, kufaka phakathi ethandwayoI-HSS cutting insertskanye namathuluzi okuguqula i-HSS, angamathuluzi okusika akhethwayo ngokunemba nokusebenza kahle. Ngokukwazi kwabo ukumelana namazinga okushisa aphezulu nokusika ngokuhlanzekile, baye baba ingxenye ebalulekile yezimboni ezihlukahlukene. Kungakhathaliseki ukuthi insimbi, izinkuni noma ipulasitiki, iIzinhlobo ze-HSSzinhle kakhulu ekuletheni imiphumela oyifunayo. Ngokusebenzisa ukunakekelwa okufanele kanye nemingcele yokusika, ochwepheshe bangakwazi ukwandisa ukusebenza nokuphila kwalawa mathuluzi okusika ahlukahlukene. Ngakho-ke ngokuzayo lapho udinga ithuluzi lokusika elinokwethenjelwa, cabangela ukufaka kwe-HSS, okunikeza ukusebenza kokusika okungenakuqhathaniswa nokuqina.

Isikhathi sokuthumela: Aug-29-2023