Amaphoyinti okuvunguzabaziwa nangokuthi ompompi bamathiphu kanye nompompi basenqenqemeni embonini yemishini. Isici esibaluleke kakhulu sesakhiwo se-isikulufa-point kampompii-screw-point groove ethambekele futhi emise okwetheyiphu ephozithivu engxenyeni engaphambili, egoqa ukusikwa ngesikhathi sokusikwa futhi sikukhiphele ngaphambi kompompi namaphakathi nembobo yesikulufu.

Ngenxa yendlela yayo ekhethekile yokususa ama-chip, iisikulufa-point kampompiigwema ukuphazanyiswa kwe-chip ne-surface yentambo eyenziwe, ukuze ikhwalithi yembobo eqediwe eqediwe ibe ngcono kune-groove evamile eqondile;

Isakhiwo se-groove esingashoni siqinisekisa ukupholisa futhi siqinise ukumelana ne-torque ekucubungulweni kompompi, ukuze sibe nesivinini esiphezulu sokujikeleza futhi sifanele ukucubungula imicu ejulile yembobo;

Ngenxa yendlela yokukhipha i-chip kampompi wethiphu yesikulufu, kuyanconywa ukwenziwa kwemishini eqondile kanye nokucupha imbobo;

Ngokuvamile, uma kuqhathaniswa nompompi bomtshingo ovunguzayo, ukuphila kompompi bamaphoyinti azungezayo kunganwetshwa okungenani izikhathi ezi-1.

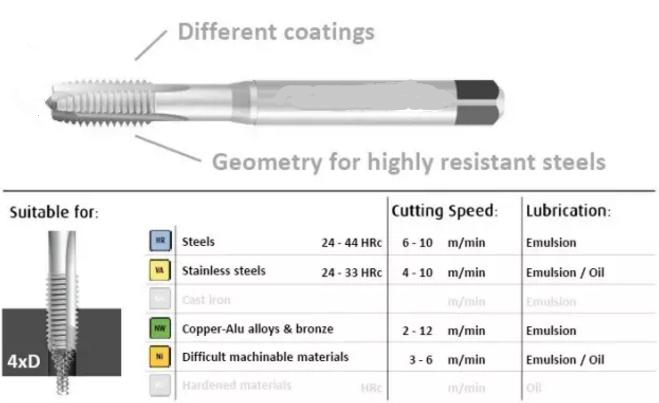

Ubulukhuni bomshini: ≤32HRC; Isivinini esinconyiwe: mayelana ne-8 ~ 12m / min; Ukupholisa okuphakathi: amafutha noma amafutha, ukupholisa i-emulsion;

*Ijubane lomshini lompompi abahlanganiswe phezulu likhuphuka ngokulingana ngo-30%

Thepha imingcele yokusika kanye nokuma kwe-groove Ngemva kokuhlolwa okuningi kokusika, siye sabeka imingcele ye-screw point kampompi yokucubungula insimbi engagqwali, insimbi ephansi, ephakathi nendawo ephezulu, i-aluminium alloy, i-alloy yethusi, njll. Imicu icutshungulwa kumishini yokugaya engenisiwe.

Isikhathi sokuthumela: Jun-14-2022