Ukushayela ngokungakhathali okuya ezimotweni ezilula, ezinamandla, nezisebenza kahle kakhulu, ikakhulukazi ngokukhula okunamandla kwezimoto zikagesi (EVs), kufaka ingcindezi enkulu ekwenziweni kwezimoto. Izindlela zendabuko zokwenza ukuxhumana okuqinile okunentambo ngeshidi elincane lensimbi - okuyisisekelo semizimba yesimanje yezimoto, amafreyimu, nezivalo - kuvame ukubandakanya izibophelelo ezingeziwe ezifana namantongomane weld noma amantongomane e-rivet. Lokhu kwethula ubunkimbinkimbi, isisindo, amaphuzu angaba khona okuhluleka, kanye nezikhathi zomjikelezo ohamba kancane. Faka i-Thermal Friction Drilling (TFD) namathuluzi ayo akhethekile -I-Carbide Flow Drill Bits kanye ne-Thermal Friction Drill Bit Sets – ubuchwepheshe obushintsha ngokushesha imigqa yokukhiqiza yezimoto ngokuzenzakalela ukudalwa kwemicu ebalulekile, enamandla aphezulu ngqo ngaphakathi kwezinto ezincane.

Inselele Yokuqiniswa Kwezimoto: Isisindo, Amandla, Isivinini

Onjiniyela bezimoto bahlale belwa nendida yokuqina kwesisindo. Izinsimbi ezizacile, eziqine kakhulu kanye nama-alloys e-aluminium kubalulekile ekwehliseni isisindo semoto nokuthuthukisa ukusebenza kahle kukaphethiloli noma ububanzi be-EV. Kodwa-ke, ukudala izintambo ezinokwethenjelwa ezithwala imithwalo kulezi zigaba ezincane kuyinkinga:

Ukusebenzelana Okunomkhawulo: Ukuthepha okuvamile eshidini elincanyana kunikeza ukubandakanyeka okuncane kwentambo, okuholela emandleni aphansi okukhipha kanye nokuba sengozini yokuhlubula.

Ukuxaka Okungeziwe Nesisindo: Amantongomane e-Weld, amantongomane e-clinch, noma ama-rivet nuts engeza izingxenye, adinga ukusebenza kwesibili (ukushisela, ukucindezela), ukwandisa isisindo, futhi wethule amasayithi okugqwala okungenzeka noma izinkinga zokulawula ikhwalithi.

Ama-Bottlenecks Okucubungula: Ukumba okuhlukene, ukufaka/okunamathiselwe kwe-fastener, kanye nezinyathelo zokuthepha kunciphisa imigqa yokukhiqiza yevolumu ephezulu.

Ukushisa & Ukuhlanekezela: Amantongomane ashisela akhiqiza ukushisa okuphawulekayo, amaphaneli amancane okungenzeka ajike noma athinte izinto ezibonakalayo endaweni Ethintekile Ukushisa (HAZ).

I-Flow Drills: Isixazululo Esizenzakalelayo Emgqeni

I-Thermal Friction Drilling, ehlanganiswe ezikhungweni zemishini ye-CNC, amaseli erobhothi, noma imishini yokuphotha eningi ezinikele, inikeza impendulo ephoqayo:

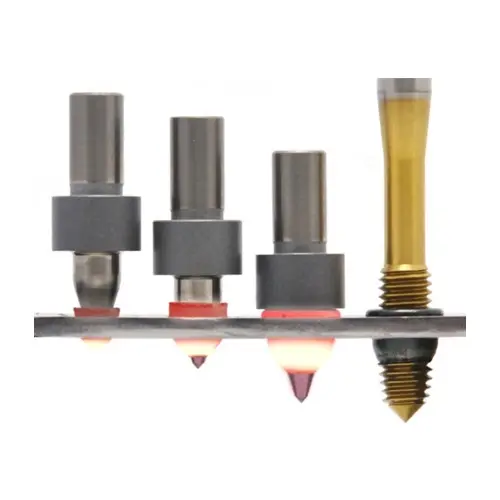

I-Single Operation Powerhouse: Umlingo oyinhloko we-TFD usekuhlanganiseni ukubhola, ukwakheka kwamabhushi, kanye nokungena ekusebenzeni okukodwa okungenamthungo, okuzenzakalelayo. I-Carbide Flow Drill Bit eyodwa, ezungezisayo ngesivinini esikhulu (imvamisa engu-3000-6000 RPM yensimbi, ephakeme nge-aluminium) ngaphansi kwamandla abalulekile e-axial, ikhiqiza ukushisa okushubile. Lokhu kwenza insimbi ibe ipulasitiki, ivumele ijiyomethri eyingqayizivele yebhithi ukuthi igeleze futhi isuse impahla, yenze isihlahla esingenamthungo, esihlanganisayo cishe izikhathi ezi-3 ukujiya kweshidi lokuqala.

Ukuthepha Ngokushesha: Njengoba i-Flow Drill ihoxisa, ukuthepha okujwayelekile (okuvame ukuba kumphathi wethuluzi ofanayo ohlelweni lokushintshisana ngokuzenzakalela noma i-spindle yesibili evunyelanisiwe) ngokushesha kulandela, ukusika imicu enembayo kulo mkhakha osanda kwakhiwa, onezindonga eziwugqinsi. Lokhu kuqeda ukuphatha phakathi kokusebenza futhi kunciphisa kakhulu isikhathi somjikelezo.

Ukuhlanganiswa Kwerobhothi: I-Thermal Friction Drill Bit Sets ifaneleka kahle izingalo zerobhothi. Ikhono labo lokwenza yonke inqubo yokudala intambo ngendlela yethuluzi elilodwa (ukubhoboza phansi, ukubhoboza ifomu, ukuhoxisa, ukucofa, ukuhoxisa) lenza ukuhlelwa kwerobhothi nokwenza kube lula. Amarobhothi angabeka kahle ithuluzi phezu kwamakhonsana ayinkimbinkimbi ezakhiweni ze-body-in-white (BIW) noma ama-sub-assemblies.

Kungani Abakhiqizi Bezimoto Besebenzisa Ama-Flow Drills:

Amandla Ochungechunge Anyuke Kakhulu: Lena inzuzo enkulu. Imicu ihlanganisa isihlahla esiwugqinsi (isb, ukwakha isihlahla esibude obuyi-9mm ukusuka eshidini elingu-3mm), okuholela ekudonselweni nasekukhipheni amandla avame ukudlula lawo amantongomane e-weld noma ama-rivet nuts. Lokhu kubalulekile ezingxenyeni ezibalulekile zokuphepha (amahange ebhande lesihlalo, okokugxumeka ukumiswa) nezindawo ezidlidliza kakhulu.

Ukunciphisa Isisindo Okubalulekile: Ukuqeda i-weld nut, i-rivet nut, noma i-clinch nut ngokwayo kususa isisindo. Okubaluleke nakakhulu, ngokuvamile ivumela abaklami ukuthi basebenzise i-gauge yezinto ezibonakalayo ezincane njengoba i-bushing eyenziwe ihlinzeka ngokuqiniswa kwendawo lapho amandla adingeka khona, ngaphandle kokwengeza isisindo kwenye indawo. Amagremu alondolozwe ekuxhumekeni ngakunye aphindaphindeka ngokushesha kuyo yonke imoto.

Ukuphumelela Kwenqubo Engenakuqhathaniswa & Isivinini: Ukuhlanganisa imisebenzi emithathu ibe izikhathi zomjikelezo owodwa wokusika. Umjikelezo ojwayelekile wokubhoboza nokuthinta okushisayo ungaqedwa kumasekhondi angu-2-6, ngokushesha kakhulu kunokubhola okulandelanayo, ukubekwa kwamantongomane/ukushisela, kanye nokuthepha. Lokhu kuthuthukisa ukuphuma kwemigqa yevolumu ephezulu.

Ikhwalithi Ethuthukisiwe Nokungaguquguquki: I-TFD ezenzakalelayo iletha ukuvumelana okukhethekile kwembobo nomgodi. Inqubo iphindaphindeka kakhulu ngaphansi kwemingcele elawulwayo ye-CNC noma yerobhothi, kuncishiswe iphutha lomuntu elivamile ekubekeni amantongomane okwenziwa ngesandla noma ekushiseleni. I-bushing eyakhiwe idala indawo yembobo ebushelelezi, evame ukuvaleka, ithuthukise ukumelana nokugqwala kanye nokunamathela kopende.

Inkimbinkimbi Yesistimu Eyehlisiwe Nezindleko: Ukuqeda okuphakelayo okuhlukene kwamantongomane, iziteshi zokushisela, izilawuli zokushisela, nokuhlolwa kwekhwalithi okuhlobene kunciphisa izindleko zempahla enkulu, izidingo zesikhala saphansi, inkimbinkimbi yokunakekelwa, kanye nezinto ezisetshenziswayo (akukho ntambo yokushisela/igesi, awekho amantongomane).

Ubuqotho Bokubambisana Okuthuthukisiwe: I-integral bushing yakha ingxenye eqhubekayo yensimbi yezinto eziyisisekelo. Abukho ubungozi bokuxega, ukuphotha, noma ukuwa kwentongomane njengemishini yokubopha, futhi akukho ukukhathazeka kwe-HAZ okuqhathaniswa nokushisela.

I-Material Versatility: I-Carbide Flow Drill Bits iphatha ngempumelelo izinto ezihlukene ezimotweni zesimanje: insimbi emnene, insimbi ye-High-Strength Low-Alloy (HSLA), Advanced High-Strength Steel (AHSS), ama-alloys e-aluminium (5xxx, 6xxx), ngisho nezinye izinto ezingenasici. Izingubo zamathuluzi (njenge-AlCrN ye-aluminium, i-TiAlN yensimbi) kuthuthukisa ukusebenza nempilo.

Ukwamukelwa Kwezicelo Eziyinhloko Zezimoto Zokutholwa:

I-EV Battery Enclosure & Trays: Mhlawumbe umshayeli oyedwa omkhulu. Lezi zakhiwo ezinkulu, ezinodonga oluncane oluncane (ngokuvamile i-aluminium) zidinga amaphuzu amaningi anamandla aphezulu, angavuzi ukuze afakwe, amakhava, amapuleti okupholisa, nezinto zikagesi. I-TFD inikeza amandla adingekayo ngaphandle kokwengeza isisindo noma ubunzima. Isihlahla esivaliwe sisiza ukuvikela ukungena kokupholisa.

I-Chassis nama-Subframes: Abakaki, ama-crossmembers, namaphoyinti okukhweza amisiwe azuza emandleni e-TFD nokumelana nokudlidliza kuzinsimbi ezizacile, eziqine kakhulu.

Amafreyimu Wezihlalo Nezindlela: Izingxenye zokuphepha ezibalulekile ezidinga amandla aphezulu kakhulu okudonsa amahange amabhande namaphoyinti okukhweza aqinile. I-TFD iqeda izinsimbi ezinkulu kanye nokuhlanekezela kwe-welding.

I-Body-in-White (BIW): Abakaki abahlukahlukene, iziqinisi, nezindawo zokukhweza zangaphakathi ngaphakathi kwesakhiwo semoto lapho amantongomane engeziwe enzima futhi ukushisela kungafuneki.

I-Exhaust Systems: Iziphanyeko ezifakwayo nezinamathiseli zesivikelo sokushisa kunsimbi encane engagqwali noma insimbi e-aluminium izuza kusukela embobeni evalwe ukugqwala nokumelana nokudlidliza.

Amayunithi e-HVAC & Ukudonsa: Amaphaneli okukhweza namaphaneli okufinyelela kusevisi adinga imicu eqinile ekuvaleni kwensimbi yeshidi elincanyana.

I-Carbide Imperative ku-Automotive TFD:

Ukwenziwa kokukhiqizwa kwezimoto kude, kufuna ukwethembeka okuphelele kwamathuluzi nokuphila isikhathi eside. Amabhithi e-Carbide Flow Drill awaxoxiswana. Zimelana namazinga okushisa okungqubuzana okwedlulele (okuvame ukudlula u-800°C/1472°F ekugcineni), isivinini esikhulu sokuzungeza, namandla abalulekile e-axial ahlangabezane nezinkulungwane zezikhathi ngokushintshana ngakunye. Izingxenye ezithuthukisiwe ze-micro-grain carbide nezingubo ezikhethekile (i-TiAlN, i-AlTiN, i-AlCrN) zenzelwe izinto ezithile zezimoto, ukukhulisa impilo yamathuluzi nokugcina ukwakheka okungaguquguquki kwesihlahla kanye nekhwalithi yembobo ebalulekile ezinqubweni ezizenzakalelayo. A enakekelwe kahleI-Thermal Friction Drill Bit Setingacubungula izinkulungwane zezimbobo ngaphambi kokudinga ukushintshwa, inikeze umnotho omuhle kakhulu wezindleko zomgodi ngamunye.

Ukuhlanganiswa Nekusasa:

Ukuhlanganiswa okuyimpumelelo kuhilela ukulawula okunembile kwe-RPM, amanani okuphakelayo, amandla e-axial, nokupholisa (ngokuvamile ukuqhuma komoya okuncane kunokupholisa izikhukhula ukuze kugwenywe ukucisha ukwakheka kwesihlahla). Amasistimu okuqapha alandelela ukuguga kwamathuluzi futhi acubungule imingcele yokulungiswa okubikezelwayo. Njengoba idizayini yezimoto iqhubekela phambili eya ezakhiweni zezinto eziningi (isb, imizimba ye-aluminium kumafreyimu ensimbi) kanye nokukhanya okukhulu nakakhulu, isidingo sobuchwepheshe be-Flow Drill sizokhula kuphela. Ikhono layo lokudala izintambo zasendaweni, eziqine kakhulu ezintweni ezizacile, ezihlukahlukene, ngokuqondile ngaphakathi kokugeleza kokukhiqiza okuzenzakalelayo, ibeka i-Thermal Friction Drilling hhayi nje njengenye indlela, kodwa njengezinga lesikhathi esizayo lokuqiniswa kwezimoto okuphumelelayo, okunamandla aphezulu. Uguquko lokwakha izimoto eziqinile, ezilula kancane ngesikhathi esisodwa.

Isikhathi sokuthumela: Aug-21-2025