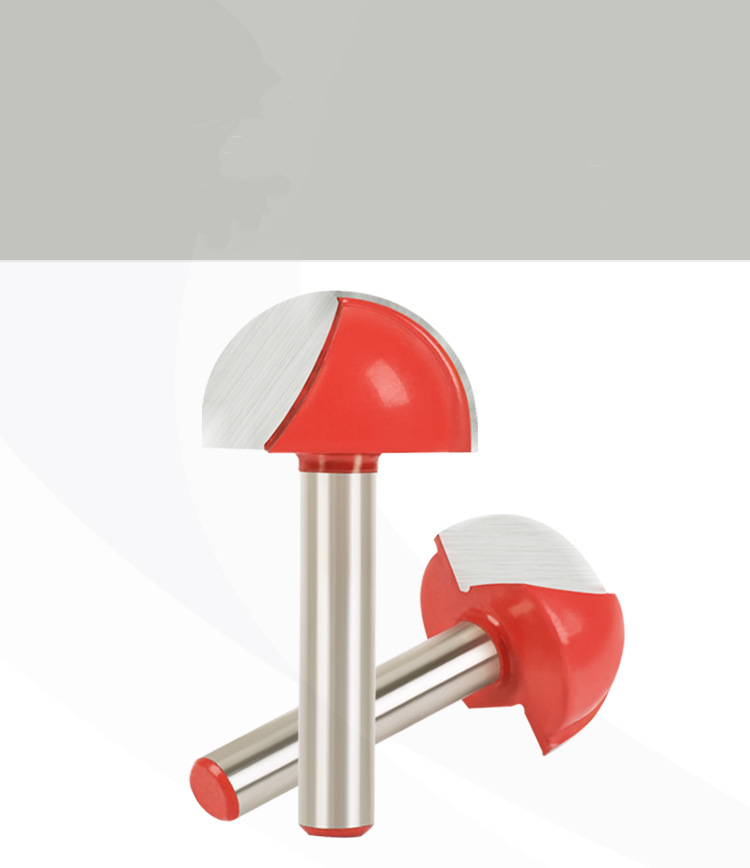

I-Milling Cutter Core Box Router Bit Round Ngezansi Eyindilinga Yekhanda Yokusika Ngokhuni

ISICI

High Frequency Welding Process

I-interface igcwele umoya, iqinile futhi akulula ukuyiphuka

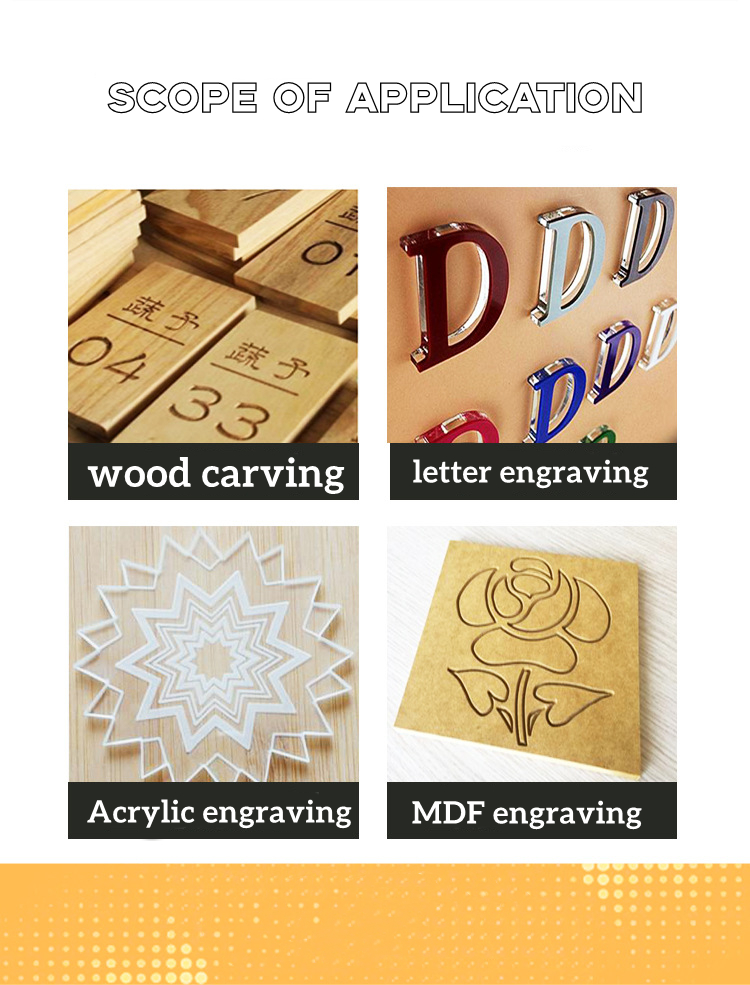

Ifanele ukuqoshwa kwezinkuni

ukuqoshwa kwencwadi

Ukuqoshwa kwe-Acrylic

Umdwebo we-MDF

Ukukhiqizwa kwensimbi ye-Tungsten, impilo ende yesevisi, ukusekelwa ngokwezifiso

Awekho ama-burrs, ukuphuma okuhle kwe-chip, unqenqema lommese obukhali, ukumelana nokugqokwa nokuqina

Ukuzinza kwesakhiwo inqubo evuthiwe / enhle futhi ihlala isikhathi eside

Ikhwalithi eyenziwe ngokwezifiso ithembekile

Impilo ende, ukuqina okuphezulu/ ukusebenza kahle kwezindleko

Isevisi ephelele, isevisi eseduze

Material Tungsten steel

Ukusika nokuqopha izinkuni, i-MDF, njll

Ububanzi bokusebenza: imboni yezimoto, i-aerospace, imboni yesikhunta, imboni ye-IT

Okunamachashaza agcwele

1.Ukwenza ngokwezifiso okufunayo / okuningi ngaphandle kweshalofu / ikhwalithi ethembekile

2.Into ekhethwayo yaseJalimane i-tungsten steel toughness / ummese ezine ezibukhali

3.Bushelelezi ngaphandle kwama-burrs

Ubuso bushelelezi futhi bukhanya, inani lama-chips likhulu, futhi umugqa uyashesha

4. Ukumelana nokugqoka kanye nokumelana nokugqwala okuphezulu

Akukho ukumelana nokugqwala ne-oxidation ezindaweni ezinomswakama

Indlela yokusebenzisa ithuluzi lomshini wokuqopha ngokhuni:

1. Abasiki be-Multi-stripe milling batuswa umshini onzima we-particleboard, njll.

2. Ummese oqoshwe ngedayimane uyanconywa ngokuqoshwa kwesibuko se-acrylic.

3. Umphumela wokusetshenziswa we-cutter ephansi, indawo engaphezulu yomkhiqizo ocutshungulwayo ayinawo ama-burrs, futhi ayikho i-rocker ngesikhathi sokucubungula.

4. Ukuze uthole ibhodi le-multi-layer kanye nokucubungula kwe-splint, kunconywa ukusebenzisa i-double-edged straight groove milling cutter.

5. Ebhodini eliphezulu lokuminyana kanye nezinkuni eziqinile, kunconywa ukusebenzisa umsiki we-ribbed.

6. Ukuze usike i-burr-free phezulu naphansi, kunconywa ukusebenzisa umphetho owodwa, onqenqemeni olukabili phezulu kanye nesisiki sokugaya esingezansi.

7. Kukhokho, i-MDF, izinkuni ezimsulwa, i-PVC, i-acrylic enkulu-scale deep relief processing, kutuswa ukusebenzisa i-single-edged helical ball end milling cutter.

8. Ukuze uthole ukunemba ukucutshungulwa okuncane kokusiza, kunconywa ukusebenzisa umsiki ojikelezayo ophansi.

9. Ukusika ipuleti le-aluminium, kunconywa ukusebenzisa i-cutter ekhethekile yokugaya i-aluminium ekhethekile. Akukho ukunamathela emmese ngesikhathi sokucubungula, isivinini esikhulu nokusebenza kahle okuphezulu.

10. Ukusika i-MDF, kunconywa ukusebenzisa i-helical milling cutter enezinhlangothi ezimbili ngokususwa kwe-chip enkulu. Inama-grooves amabili aphezulu okukhipha ama-chip kanye nomklamo ohlangene kabili, ongenawo umsebenzi omuhle wokukhipha i-chip, kodwa futhi ufinyelela ibhalansi yethuluzi elihle. Lapho ucubungula amabhodi aphakathi nendawo naphezulu, anezici zokungabi mnyama, akukho umusi we-cap, nempilo ende yesevisi.

11. Ukusika i-acrylic, kunconywa ukusebenzisa i-spiral milling cutter ene-single-edged spiral, ebonakala ngokucubungula okungenantuthu nokungenaphunga, isivinini esisheshayo, ukusebenza kahle okuphezulu, akukho-chips okunamathelayo, futhi kuyahambisana ngempela nemvelo. Inqubo yayo ekhethekile yokukhiqiza iqinisekisa ukuthi i-acrylic ngeke iqhume. , Iphethini yommese enhle kakhulu (ngisho nangaphandle kwephethini yommese), ubuso bushelelezi futhi bushelelezi. Indawo esebenza ngomshini idinga ukufeza umphumela oyisithwathwa, futhi kuyanconywa ukuthi usebenzise isisiki sokugaya esinemiphetho emithathu esinemiphetho emithathu.