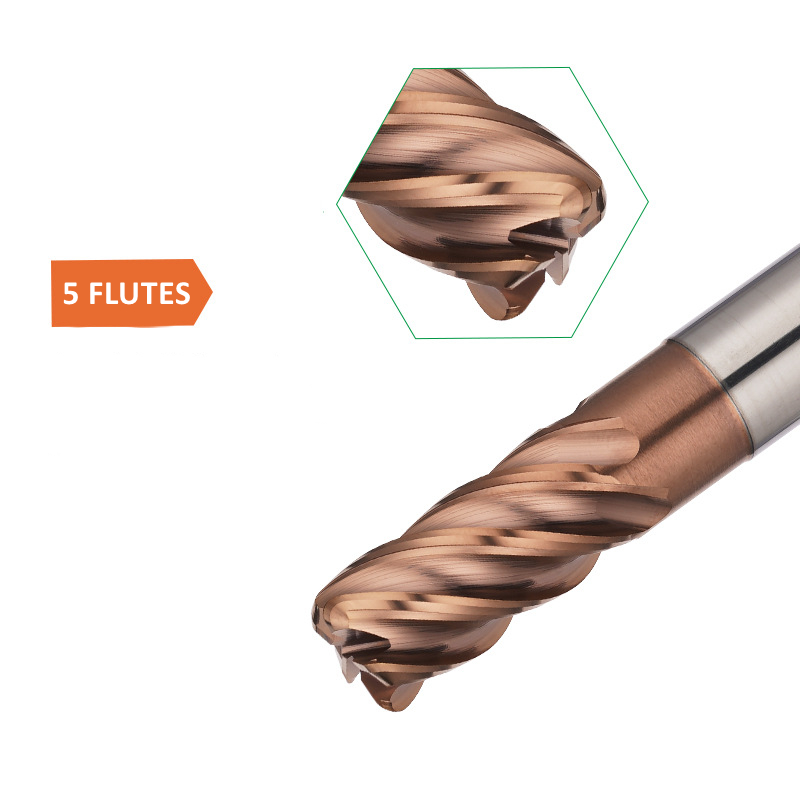

I-Corn Radius Mill Ye-Nickel-based High-Temp Alloys

INCAZELO YOMKHIQIZO

I-Titanium iwumsebenzi owaziwa kakhulu onzima ukuwumshini, ikakhulukazi ezindleleni zamathuluzi ezinolaka, njengalezo ezihlotshaniswa ne-High Efficiency Milling (HEM). Lesi sisiki se-radius milling ekhoneni sisetshenziselwa ngokukhethekile ukucubungula izinto embonini yezindiza. Yamukela isitokwe sebha yensimbi ye-tungsten engenisiwe futhi inempilo ende yesevisi.

ISINCOMO SOKUSETSHENZISWA EZINKUFUNDENI

Ingxubevange ye-Titanium TC18-21, i-ferrite, i-high-nickel alloy engaphezu kuka-35%, insimbi engagqwali enezinga eliphezulu lokushisa, i-nickel-chromium-cobalt nezinye izingxubevange eziqinile ze-titanium okunzima ukuzisika, izinto zengxubevange ezisezingeni eliphezulu.

Idizayini enemitshingo emi-5 ishesha ngo-30% -40% kunesisiki sokugaya esingu-3-flute/4-flute

Idizayini yokuzamazama komhlaba/Izinga eliphezulu Lokususwa Kwensimbi Ephakeme/Ingcindezi Yangaphakathi Ephansi

| Ububanzi beFlute | I-D6-D12 | Ubude Bomtshingo | 8-24mm |

| Uhlobo lomtshingo | I-Helical | Okubalulekile | I-tungsten yezinga eliphezulu |

| Ukugqoka | Yebo | Ibhrendi | I-MSK |

| Icubungula Ububanzi | Izinto okunzima ukuzisika njengama-titanium alloys, ama-superalloy, ama-ferrites, imizimba ye-nickel, izinsimbi ezingenasici ezisezingeni eliphezulu, kanye ne-nickel-chromium-cobalt | ||

| Imishini Esebenzayo | Imishini yokugaya, izikhungo zemishini ye-CNC, izinsimbi zekhompyutha, imishini yokuqopha | ||

ISICI

1.Ikhethekile ye-Titanium /superalloy okunzima ukusika izinto

Ifakwe okokugcoba okuphezulu kanye ne-coefficient ephansi ye-coefficient coefficient ukunciphisa ingcindezi yangaphakathi yezinto ezicutshunguliwe.

2.I-Geometry Flute

Idizayini enhle kakhulu ye-U-groove yejiyomethri ye-5-blade ingakhuphula indawo yokuxhumana nezinto ezizocutshungulwa, kuyilapho ikhulisa ukuqina kwethuluzi futhi iqinisekisa ubulukhuni obuphezulu bomhlaba.

3.Ibha yensimbi ye-tungsten engenisiwe

Ukunemba kokubekezelela i-Shank kwe-H5, okuklanyelwe ngokukhethekile amasistimu okubamba ama-shank anembe kakhulu.

4.Chamfer design

Kwenze kube lula ukubotshwa.

5.I-Seismic Design

Izinga eliphezulu lokususa insimbi, ingcindezi ephansi yangaphakathi, 30% -40% ngokushesha kunama-milling cutters endabuko angama-3/4-blade

Isicelo:

I-Aerospace, ezempi, izingxenye zemishini, izimoto, ukuxhumana okukhethekile kwe-elekthronikhi neminye imikhakha

Inothi lomthengi:

1. Ngaphambi kokusebenzisa ithuluzi, sicela ulinganise ukuchezuka kwethuluzi. Uma ukunemba kokuchezuka kwethuluzi kudlula u-0.01mm, sicela ukulungise ngaphambi kokusika.

2. Ubude bethuluzi eliphuma ku-chuck bufushane, buba ngcono. Uma ithuluzi lihlala isikhathi eside, isivinini, izinga lokuphakelayo kanye nenani lokusika lidinga ukuncishiswa.

3. Ngesikhathi sokusika, uma ukudlidliza okungavamile noma umsindo kwenzeka, sicela wehlise isivinini kanye nenani lokusika kuze kube yilapho isimo siba ngcono.

4. Ukupholisa insimbi kungcono kakhulu ukufutha kanye nejethi yomoya, engathuthukisa umphumela wokusetshenziswa komsiki wokugaya. Ama-alloys e-Titanium namanye ama-superalloys awanconywa.