I-HRC65 Black Nano-Tech Stainless Processing Flat End Mill

Isici:

1. Insimbi ye-Tungsten ithole izinhlayiya ezinhle + imishini yokukhiqiza engenisiwe.

Sisebenzisa u-100% we-tungsten carbide base material, futhi senqaba ukusebenzisa izinto ezigaywe kabusha noma izinto eziphingayo.

2.Singenise imishini ye-SACCKE evela eJalimane ukuze igaye kahle ukuze sifinyelele ukunemba okuzinzile nokuqeda okuphezulu.

3.Ukuhlukaniswa okungalingani kanye ne-engeli ye-helix engalingani ukuze kugwenywe i-resonance futhi kwandiswe ukuqedwa okungaphezulu kwezingxenye ezicutshunguliwe.

4.HRC65.

I-5.I-Swiss ingenise i-ALoCa coating, ukushisa ukushisa nokumelana nokushisa okuphezulu, ukugaya okuphezulu kokuqina.

~ 3500HV Ubulukhuni bokunamathela kanye nezinga lokushisa elingu-950 degree anti-oxygen.

Inqubo ye-6.Isinyathelo/umtshingo ovunguzayo wokugaya ogcwele, ukususwa kwe-chip ebushelelezi ngesikhathi sokusika ngesivinini esikhulu, akukho ukuqoqwa kwe-chip/akukho ukunqwabelana kwe-chip, kuthuthukisa kakhulu ukusebenza kahle kokukhiqiza nokuthuthukisa isiphetho se-workpiece.

| Imitshingo | 4 | Okubalulekile | I-Titanium alloy, insimbi engagqwali | ||||||||||

| Uhlobo | Uhlobo lwekhanda eliyisicaba | Ukuqina | HRC65 | ||||||||||

| Iphakheji |

| Ibhrendi | I-MSK | ||||||||||

| Ububanzi beFlute(mm) | Ubude Bomtshingo(mm) | I-Shank Diameter(mm) | Ubude(mm) | ||||||||||

| 1 | 3 | 4 | 50 | ||||||||||

| 1.5 | 4 | 4 | 50 | ||||||||||

| 2 | 6 | 4 | 50 | ||||||||||

| 2.5 | 7 | 4 | 50 | ||||||||||

| 3 | 8 | 4 | 50 | ||||||||||

| 4 | 11 | 4 | 50 | ||||||||||

| 5 | 13 | 6 | 50 | ||||||||||

| 6 | 15 | 6 | 50 | ||||||||||

| 8 | 20 | 8 | 60 | ||||||||||

| 10 | 25 | 10 | 75 | ||||||||||

| 12 | 30 | 12 | 75 | ||||||||||

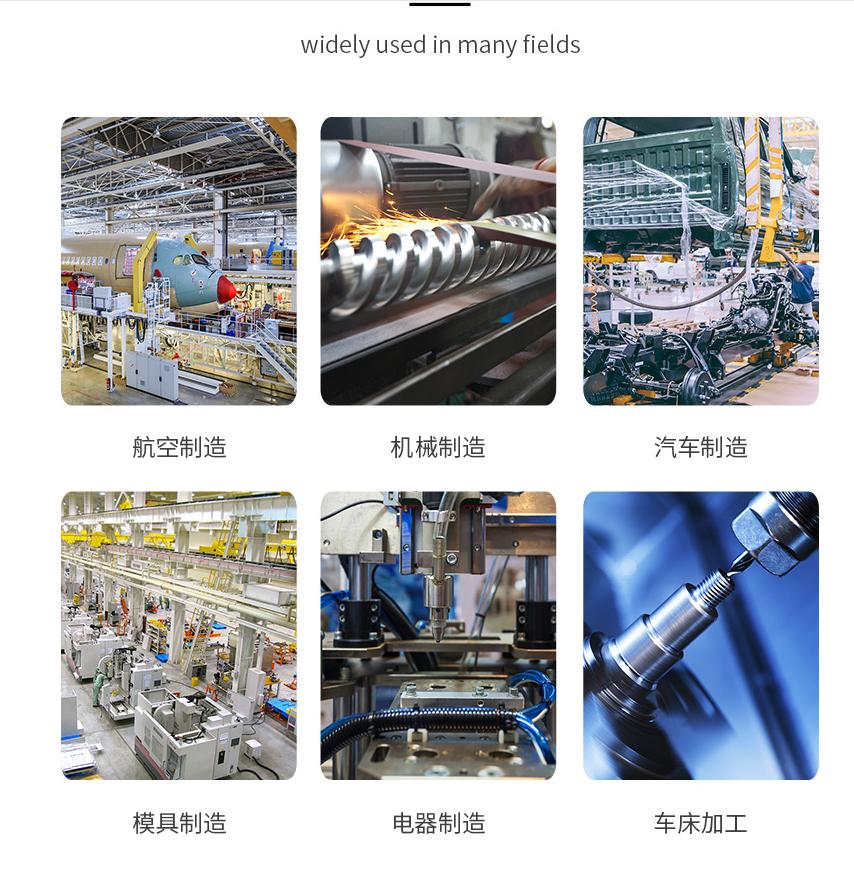

Sebenzisa:

Kusetshenziswa kabanzi emikhakheni eminingi

Aviation Manufacturing

Ukukhiqizwa Kwemishini

Umkhiqizi wezimoto

Ukwenza isikhunta

Ukukhiqiza Ugesi

I-Lathe processing