Ikhwalithi Enhle ye-HRC 55 Solid Carbide Reamer yomshini we-CNC

Sethula isisiki sethu sehinge esiqinile, esiziqhayisa ngobulukhuni obumangalisayo be-HRC55. Leli thuluzi lenziwe ngobunyoninco ukuze linikeze ukuqina okukhethekile nokunemba ezinhlobonhlobo zezinhlelo zokusebenza. Isilinganiso se-HRC55 siqinisekisa ukuthi i-blade igcina ubukhali bayo ngokusetshenziswa okunwetshiwe, iqinisekisa ukusebenza okungaguquguquki nokuthembekile. Kungakhathaliseki ukuthi usebenza kumaphrojekthi okusebenza ngokhuni ayinkimbinkimbi noma izicelo zensimbi ezifuna ngamandla, lesi sisiki sehinge siklanyelwe ukuhlangabezana nezindinganiso eziphakeme kakhulu, okusenza sibe yithuluzi elibaluleke kakhulu lezingcweti nezingcweti ngokufanayo. Tshala imali ngokunemba nokuphila isikhathi eside ngesisiki sethu sehinge esiqinile se-HRC55.

| Ububanzi bomtshingo(d) | Ubude bomtshingo(L) | Ubude obuphelele(L) | Ububanzi be-Shank(D) | Inombolo yemitshingo(F) |

| 1 | 15 | 50 | 1 | 4 |

| 1.5 | 15 | 50 | 1.5 | 4 |

| 2 | 15 | 50 | 2 | 4 |

| 2.5 | 15 | 50 | 2.5 | 4 |

| 3 | 20 | 50 | 3 | 4 |

| 3.5 | 20 | 50 | 3.5 | 4 |

| 4 | 20 | 50 | 4 | 4 |

| 4.5 | 22 | 50 | 4.5 | 4 |

| 5 | 22 | 60 | 5 | 4 |

| 5.5 | 25 | 60 | 5.5 | 4 |

| 6 | 25 | 60 | 6 | 6 |

| 7 | 28 | 69 | 7 | 6 |

| 8 | 28 | 70 | 8 | 6 |

| 9 | 32 | 80 | 9 | 6 |

| 10 | 32 | 80 | 10 | 6 |

| 11 | 35 | 80 | 11 | 6 |

| 12 | 35 | 80 | 12 | 6 |

| 13 | 50 | 100 | 13 | 6 |

| 14 | 50 | 100 | 14 | 6 |

| 15 | 50 | 100 | 15 | 6 |

| 16 | 50 | 100 | 16 | 6 |

| 18 | 50 | 100 | 18 | 6 |

| 20 | 50 | 100 | 20 | 6 |

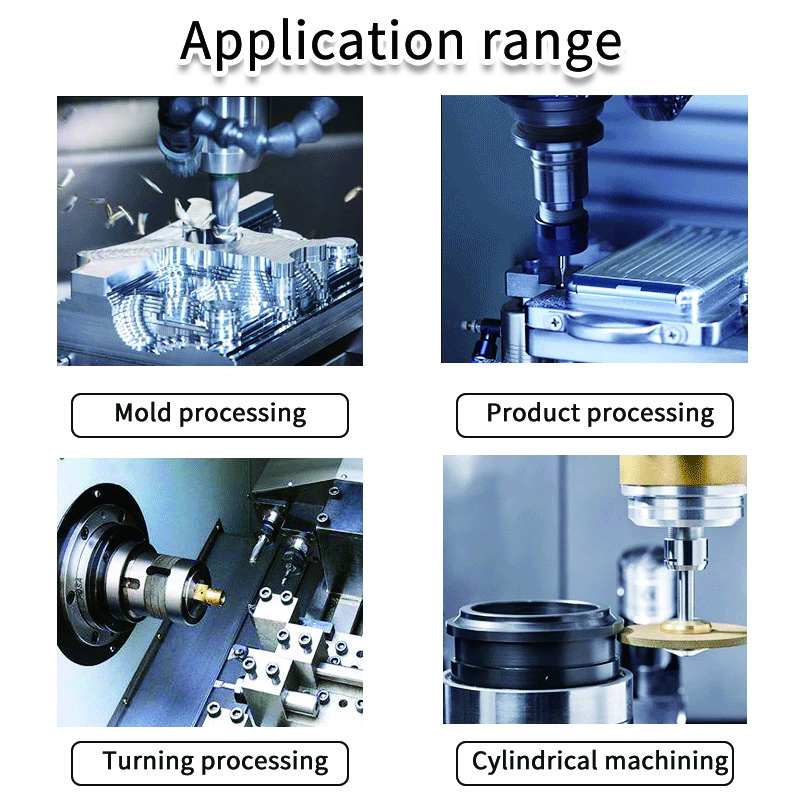

I-reamer iyithuluzi elisebenza ngezindlela eziningi elisetshenziswa kabanzi ekwenzeni insimbi ukusika nokubumba izinhlobonhlobo zezinsimbi. Ithuluzi liqukethe i-blade eqinile kanye nesibambo esenza ukusikeka okunembile ezindaweni zensimbi ngokubuyisela ngesandla noma ngokumshini i-blade.

Leli thuluzi lidlala indima ebaluleke kakhulu ezimbonini ezehlukene ezifana nezokukhiqiza, ezokwakha kanye nezokulungisa. Ububanzi bayo bezinhlelo zokusebenza buyenza ibe yimpahla ebaluleke kakhulu enqubweni yokusebenza kwensimbi, inikeze ukusekelwa okubalulekile kwemisebenzi edinga ukunemba, ukusebenza kahle kanye nokuguquguquka.

| Ibhrendi | I-MSK | Ukupakisha | Ibhokisi lepulasitiki noma elinye |

| Okubalulekile | 20CrMnTi | Ukusetshenziswa | I-Cnc Milling Machine Lathe |

| Usekelo olwenziwe ngokwezifiso | OEM, ODM | Uhlobo | I-NBT-ER |

Lokho amakhasimende akusho ngathi

FAQ

Q1: Singobani?

I-A1: I-MSK (Tianjin) Cutting Technology Co., Ltd. yasungulwa ngo-2015. Iyakhula futhi isidlulile e-Rheinland ISO 9001

Ngemishini yokukhiqiza ethuthukisiwe yomhlaba wonke efana nesikhungo sokugaya i-SACCKE esiphezulu se-axis emihlanu eJalimane, isikhungo sokuhlola amathuluzi e-ZOLLER e-axis six-axis eJalimane, namathuluzi omshini we-PALMARY e-Taiwan, izibophezele ekukhiqizeni amathuluzi e-CNC aphezulu, achwepheshe, asebenza kahle futhi ahlala isikhathi eside.

Q2: Ingabe uhweba inkampani noma umenzi?

A2: Singabakhiqizi bamathuluzi e-carbide.

Q3: Ungakwazi yini ukuthumela umkhiqizo kumthengisi wethu e-China?

I-A3: Yebo, uma unomdluliseli e-China, siyajabula ukuthumela imikhiqizo kuye.

Q4: Yimiphi imigomo yokukhokha engamukelwa?

A4: Ngokuvamile samukela i-T/T.

Q5: Ingabe uyawamukela oda OEM?

I-A5: Yebo, i-OEM nokwenza ngokwezifiso kuyatholakala, futhi sinikeza insizakalo yokuphrinta ilebula yangokwezifiso.

Q6: Kungani usikhethe?

1) Ukulawulwa kwezindleko - thenga imikhiqizo yekhwalithi ephezulu ngentengo efanelekile.

2) Impendulo esheshayo - kungakapheli amahora angama-48, ochwepheshe bazokunikeza izingcaphuno futhi baxazulule ukungabaza kwakho

cabangela.

3) Ikhwalithi ephezulu - inkampani ihlale ifakazela ngenhliziyo eqotho ukuthi imikhiqizo ehlinzekayo isezingeni eliphakeme elingu-100%, ukuze ungabi nazinkathazo.

4) Isevisi yangemuva kokuthengisa kanye nesiqondiso sobuchwepheshe - sizohlinzeka ngesevisi eyenziwe ngokwezifiso kanye nesiqondiso sobuchwepheshe ngokuya ngezidingo zakho.

I-reamer, ithuluzi elibalulekile ekwenzeni imishini enembile, idlala indima ebalulekile ekuzuzeni ubukhulu obunembile kanye nokuqedwa okubushelelezi emigodini eyenziwe ngomshini. Ehlanganisa idizayini elula kodwa eyinkimbinkimbi, i-remerer iyisibonelo sobuciko obucophelelayo obufunwa izimboni ezihlukahlukene. Ake sihlole ubunkimbinkimbi baleli thuluzi, sihlole imisebenzi yalo, izinhlelo zokusebenza, kanye nokubaluleka emhlabeni wemishini.

Idizayini kanye nezingxenye:

I-reamer ngokuvamile iqukethe uchungechunge lwamaphethelo okusika ahlelwe ngomzimba oyi-cylindrical. Amaphethelo okusika, ngokuvamile asesimweni semitshingo eqondile noma eyi-helical, aklanyelwe ukususa izinto kancane kancane njengoba ithuluzi lizungeziswa. Umzimba we-reamer wenziwe ngensimbi enesivinini esikhulu, i-carbide, noma ezinye izinto ezihlala isikhathi eside, okuqinisekisa ukuphila isikhathi eside nokuqina ngaphansi kwezimo ezidingekayo zomshini.

Ukusebenza:

Umsebenzi oyinhloko we-remer iwukucwenga kanye nosayizi wembobo ebhojwe ngaphambilini. Ngokungafani nama-drill adala izimbobo, ama-reamers anikeza ukuthinta kokuqeda, okuqinisekisa ukuthi imbobo ihlangabezana nezidingo ezinembile zobukhulu. Basusa noma yikuphi ukungahambi kahle okushiywe inqubo yokumba, bathuthukise ukunemba nokuqedwa kwendawo yomgodi owenziwe ngomshini. Ama-Reamers afika ngezinhlobo ezahlukahlukene, kufaka phakathi i-straight-fluted, spiral-fluted, futhi elungisekayo, ngayinye yakhelwe ukubhekelela izidingo ezithile zomshini.

Izicelo:

Ukuguquguquka kwezinto ezivuselelayo kuthola ukusebenza ezimbonini eziningi, ezifaka i-aerospace, ezezimoto, ezokwelashwa, nezokukhiqiza. Kubunjiniyela be-aerospace nobunjiniyela bezimoto, lapho ukunemba kubaluleke kakhulu, izixhumi zisebenza kabusha ekudaleni izimbobo zezingxenye ezibalulekile njengezingxenye zenjini nezixhumi. Emkhakheni wezokwelapha, lapho ukukhiqizwa kwezimila kudinga ukunemba okukhulu, ama-reamers anomthelela ekudaleni izimbobo zezingxenye zokufakelwa.

Precision Machining:

Enye yezimfanelo ezibalulekile zama-reamers amandla abo okuthola ukubekezelelana okuqinile. Omashini bathembele kulawa mathuluzi ukuze bacubungule kahle ubukhulu bembobo ngaphakathi kwemikhawulo emincane kakhulu. Ukunemba okunikezwa ama-reamers kubalulekile ezimbonini lapho izingxenye kufanele zihlangane ngaphandle komthungo, ziqinisekise ukusebenza okuphelele nobuqotho besakhiwo.

Izinhlobo zama-Reamers:

Izidingo ezihlukene zomshini ziholele ekwakhiweni kwezinhlobo ezahlukahlukene zama-reamers. Ama-reamers aqondile afaneleka kahle ekusetshenzisweni kwenjongo evamile, kuyilapho ama-reamers a-spiral-fluted enza kahle kakhulu emisebenzini edinga ukususwa kwe-chip okuphumelelayo. Izivuseleli ezilungisekayo zinikeza ukuguquguquka ekufinyeleleni osayizi bembobo abahlukene ngaphandle kwesidingo samathuluzi amaningi. Uhlobo ngalunye lubhekelela izimo ezithile zokwenza imishini, ezibonisa ukuguquguquka kwezimo ezishintshashintshayo kuzilungiselelo ezihlukahlukene zezimboni.

Izinselelo Nokucatshangelwa:

Nakuba ama-reamers ebaluleke kakhulu ekuzuzeni ukunemba, ochwepheshe bemishini kufanele bacabangele izici ezifana nokuqondanisa kwamathuluzi, isivinini, namazinga okuphakelayo ukuze kuqinisekiswe ukusebenza kahle. Ukugcina imiphetho ebukhali kubalulekile ukuze kuzuzwe imiphumela engaguquki, futhi ukuhlolwa ngezikhathi ezithile nokugaywa kabusha kuba yingxenye yokunakekelwa okujwayelekile ukuze kugcinwe ukusebenza kwethuluzi.

Sengiphetha, i-reamer imelela njengobufakazi bokunemba okufunwa izinqubo zesimanje zomshini. Ikhono layo lokucwenga kanye nosayizi wezimbobo ezenziwe ngomshini ngokunemba kanye ne-finesse liyenza ibe yitshe legumbi ezimbonini lapho ikhwalithi nokunemba kungaxoxiswana khona. Njengoba ubuchwepheshe buthuthuka, i-remerer iyaqhubeka nokuvela, ijwayelana nesimo sezwe esishintsha njalo sokukhiqiza futhi ihlale iyithuluzi elibalulekile ekuphishekeleni impumelelo ekwenzeni imishini enembayo.