HRC55 Metric Carbide Isinyathelo Ukushayelwa Kwensimbi

Izici:

Ukubhoboza kanye ne-chamfering

Ukukhishwa kwe-chip okubushelelezi

Insimbi ethandwayo ye-tungsten

Ifanele ukubhoboza imbobo yesinyathelo ngesikhathi esisodwa

Inzuzo:

1. Imitshingo emikhulu ye-chip ingaqinisekisa ngempumelelo ukususwa kwe-chip ebushelelezi futhi ithuthukise ukusebenza kahle kwemishini

2. I-AlTiN/TiSiN/AlTiSiN/TiN/ngaphandle kokujiya, zonke ziyatholakala

3. I-carbide enosimende

Isebenzisa isisekelo sensimbi ye-tungsten eqinile, inobulukhuni obuphakeme namandla okugoba angcono, ithuluzi alikwazi ukuguga, akulula ukulicucuza nokuphuka, futhi linempilo ende yesevisi.

4. Kulula ukusebenzisa i-chamfering

Isakhiwo se-chamfered shank kulula ukusibopha.

Amathiphu Okunakekela I-Step Drill Bit

Uma ukwazi ukuphatha ukunakekela ithuluzi lakho ngendlela efanele, lizosebenza inhloso isikhathi eside. Ngale ndlela, ngeke kudingeke ukuthi uchithe imali eyengeziwe ekuthengeni ikhithi entsha maduze. Manje, ingabe kuyinselele kakhulu ukunakekela kahle ikhithi yokubhoboza isinyathelo? Lutho neze, kulula njengoba kungaba. Manje, ake sifunde indlela yokwenza kahle.

Isinyathelo 1: Udinga ukuhlanza izingcezu ngezikhathi ezithile phakathi nomsebenzi. Uma kungenjalo, izoba sengozini yokulimala ngokushesha kunalokho obekulindelwe.

Isinyathelo sesi-2: Kufanele usule kancane uma usuqedile ngomsebenzi.

Isinyathelo sesi-3: Khuhla noma iyiphi imfucumfucu usebenzisa isixubho.

Isinyathelo sesi-4: Ungasebenzisa uwoyela womshini ngemuva kwalokho kumabhithi.

| Uhlobo lwesandla | Isibambo esiqondile | I-Workpiece Material | Izinto zensimbi ezifana ne-iron, ithusi, i-aluminium, i-alloy steel, i-cast iron, njll. |

| Ibhrendi | I-MSK | Okubalulekile | I-Carbide |

| Umsebenzi | Geza izimbobo ezinezitebhisi, ama-counterbore chamfers | Ububanzi bekhanda elincane(mm) | 3.4-14.0 |

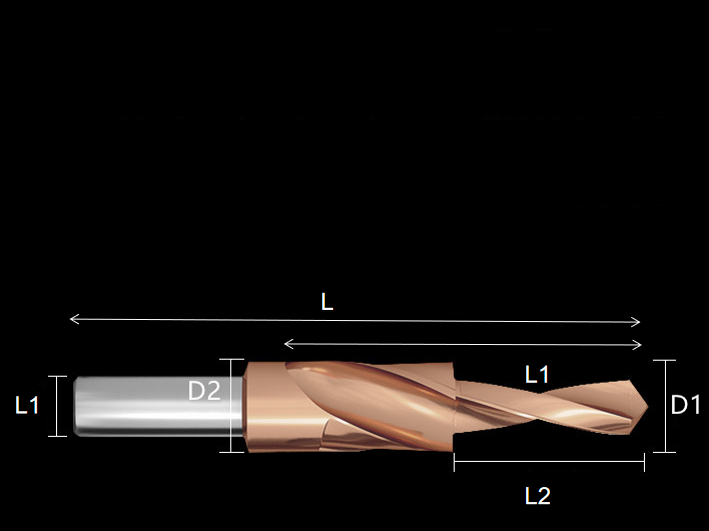

| I-D1(mm) | I-D2(mm) | L(mm) | L1(mm) | L2(mm) |

| 3.4 | 6.5 | 65 | 35 | 13 |

| 4.5 | 8.0 | 75 | 42 | 18 |

| 5.5 | 9.5 | 85 | 50 | 22 |

| 6.6 | 11.0 | 90 | 53 | 25 |

| 9.0 | 14.0 | 95 | 53 | 28 |

| 11.0 | 17.5 | 105 | 63 | 30 |

| 14.0 | 20.0 | 110 | 68 | 32 |