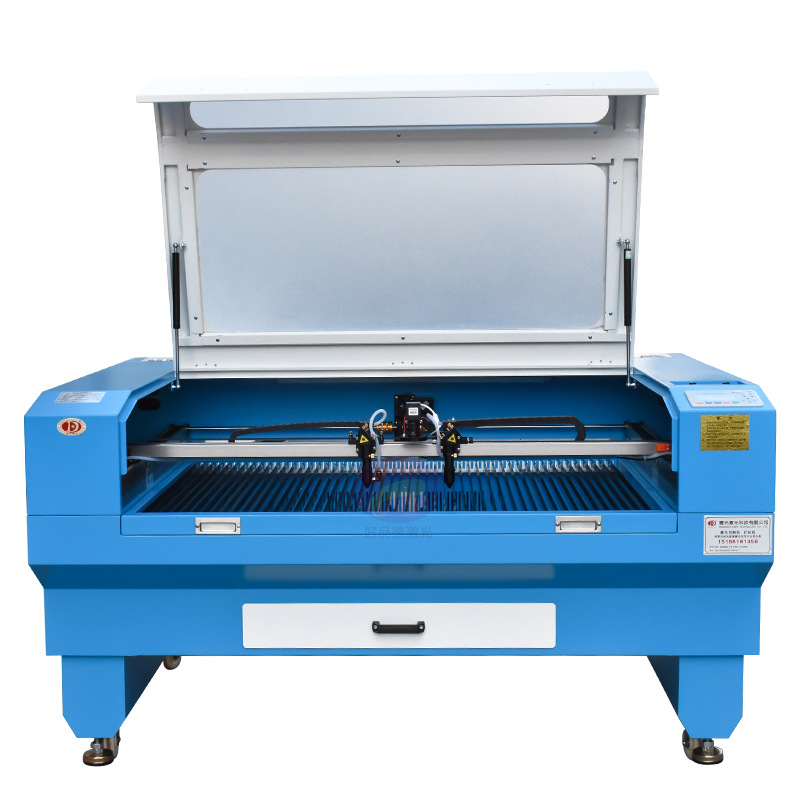

Ikhwalithi Enhle 450W Co2 Laser Wood Cutting For Wood

Izici

1. Ngokushesha nangempumelelo kakhudlwana

Amandla aphezulu afanele ukusika amapulangwe awugqinsi

2.450W ukusika amandla aphezulu

Isivinini esizinzile sokukhanya, akukho kukhanya okudukayo, amandla okungena anamandla

3. Chiller

I-chiller yomthamo wokupholisa ophezulu: ilungele ukusetshenziswa kwamandla aphezulu, ingapholisa ngokuzenzakalelayo futhi idlale indima yokuvikela

4. Ikhanda le-laser

Ikhanda le-laser lekhwalithi ephezulu: ilungele ukusetshenziswa kwamandla aphezulu, ikhwalithi engcono futhi ihlala isikhathi eside

5. Amalensi e-Premium

Ifanele ukusetshenziswa kwamandla aphezulu, ikhwalithi engcono nokusebenza kahle okuphezulu

Ukulungiselela ngaphambi kokusebenzisa umshini wokusika we-laser

1. Hlola ukuthi ingabe i-voltage yokuphakela amandla iyahambisana yini ne-voltage elinganiselwe yomshini ngaphambi kokusetshenziswa, ukuze ugweme ukulimala okungadingekile.

2. Hlola ukuthi kukhona yini insalela yendaba yangaphandle etafuleni lomshini, ukuze ungaphazamisi ukusebenza okujwayelekile kokusika.

3. Hlola ukuthi ukucindezela kwamanzi okupholisa kanye nezinga lokushisa lamanzi le-chiller kujwayelekile yini.

4. Hlola ukuthi ingcindezi yegesi eyisizayo yokusika ijwayelekile yini.

Ungawusebenzisa kanjani umshini wokusika we-laser

1. Lungisa izinto ezizonqunywa endaweni yokusebenza yomshini wokusika we-laser.

2. Ngokusho kwezinto kanye nobukhulu beshidi lensimbi, lungisa imingcele yemishini ngokufanele.

3. Khetha amalensi namabhomu afanelekile, futhi uwahlole ngaphambi kokuqala umshini ukuze uhlole ubuqotho nokuhlanzeka kwawo.

4. Lungisa ikhanda lokusika endaweni efanele yokugxila ngokusho kobukhulu bokusika kanye nezidingo zokusika.

5. Khetha igesi yokusika efanelekile futhi uhlole ukuthi isimo sokukhishwa kwegesi sihle yini.

6. Zama ukusika indaba. Ngemva kokusikwa kwezinto, hlola ukuma, ukugoqa kwendawo enqunyiwe nokuthi ngabe kukhona i-burr noma i-slag.

7. Hlaziya indawo yokusika futhi ulungise imingcele yokusika ngokufanele kuze kube yilapho inqubo yokusika yesampula ihlangabezana nezinga.

8. Yenza uhlelo lwemidwebo ye-workpiece kanye nokuhlelwa kwayo yonke ibhodi yokusika, futhi ungenise uhlelo lwesofthiwe yokusika.

9. Lungisa ikhanda lokusika kanye nebanga lokugxila, lungisa igesi elisizayo, bese uqala ukusika.

10. Hlola inqubo yesampula, futhi ulungise imingcele ngesikhathi uma kukhona noma iyiphi inkinga, kuze kube yilapho ukusika kuhlangabezana nezidingo zenqubo.