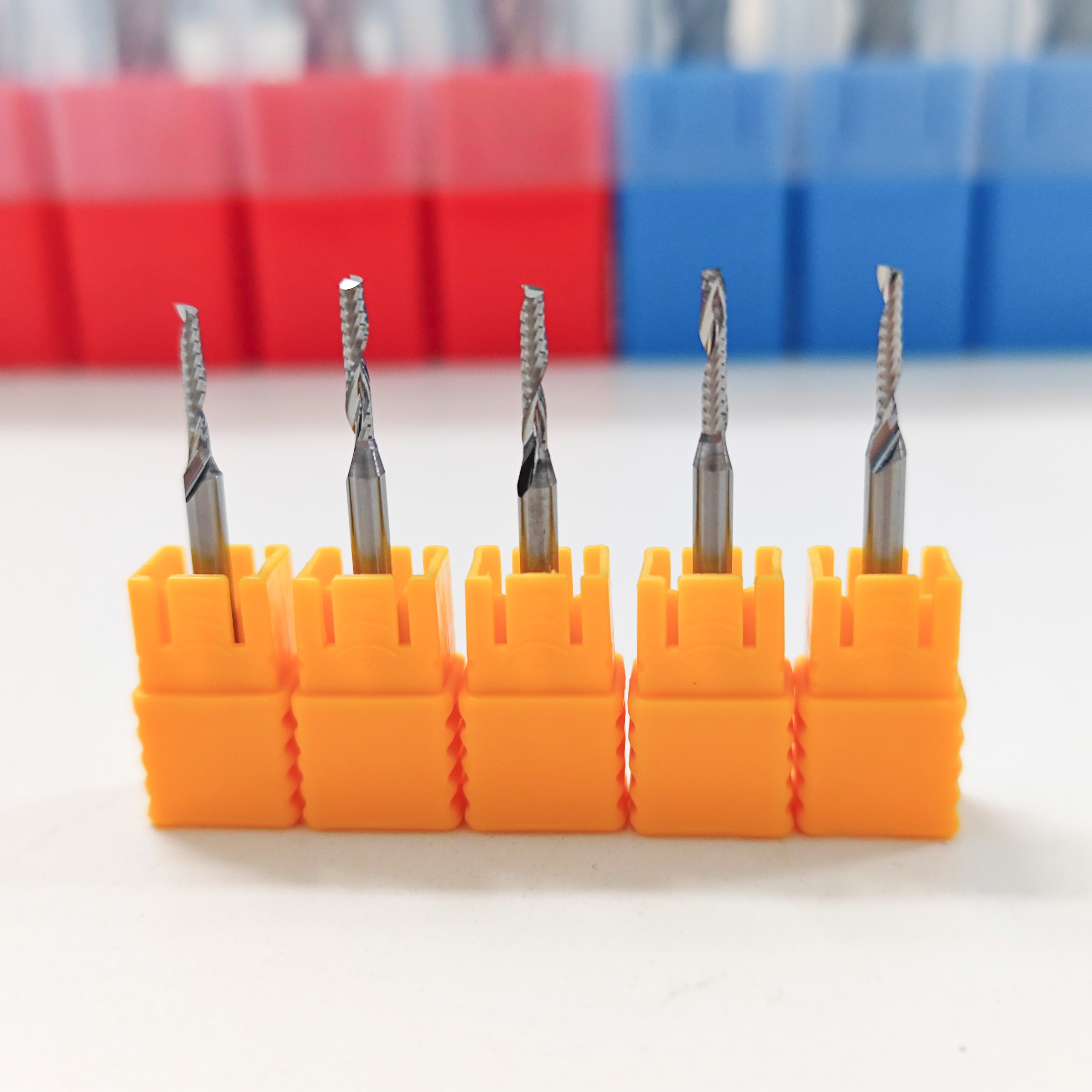

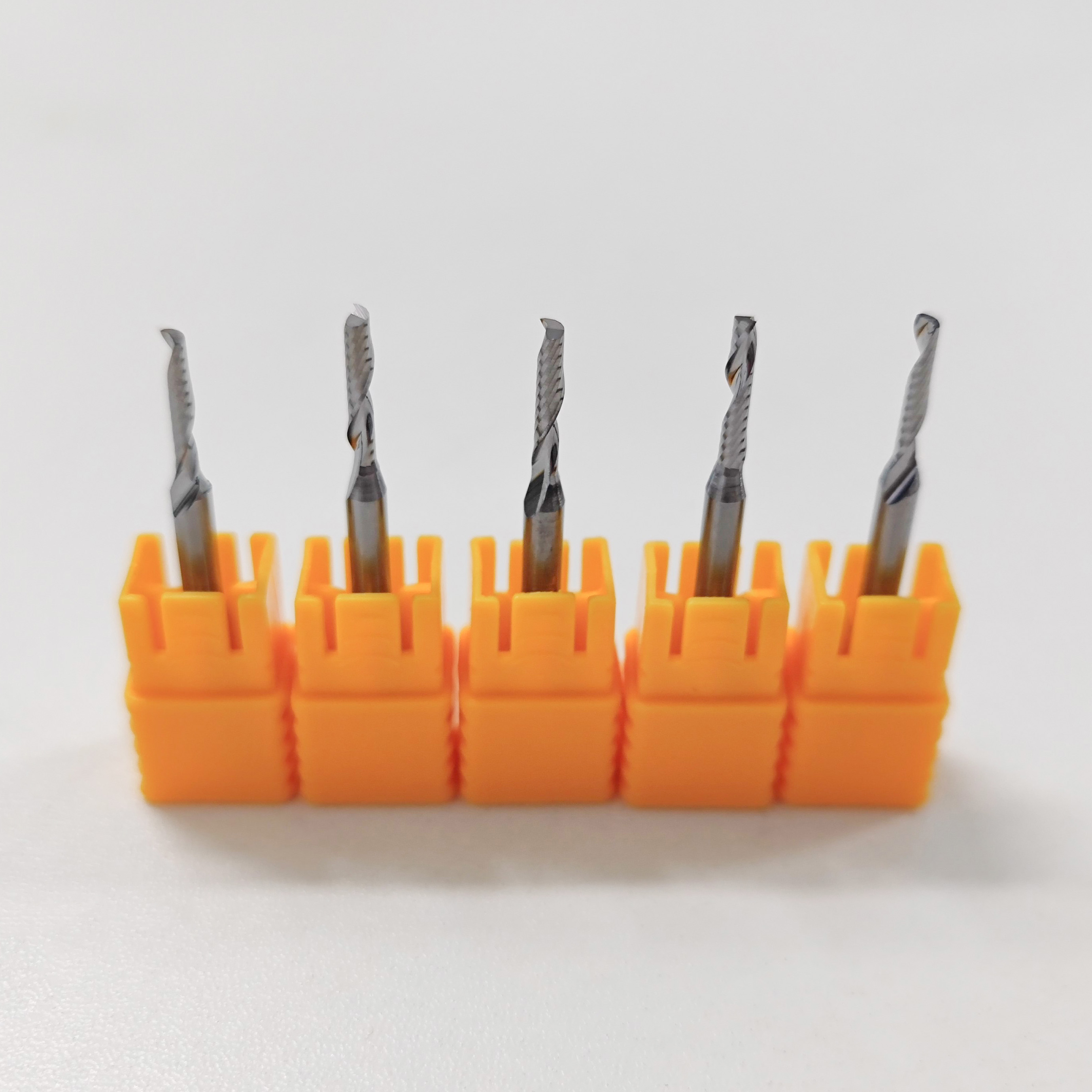

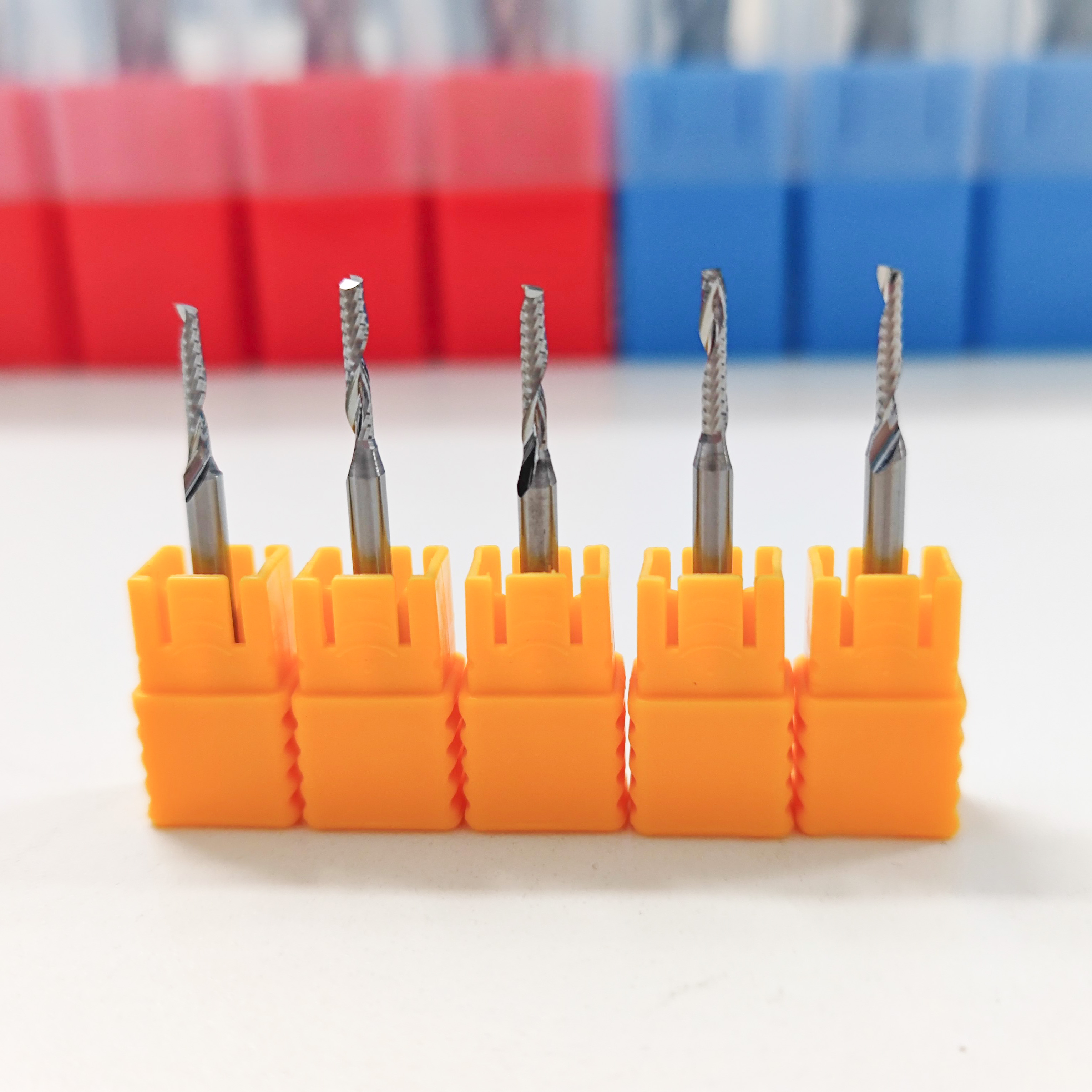

CNC Metal Milling Ithuluzi Single Flute Spiral Cutter

Isingeniso Somkhiqizo

Imanuwali Yokusebenza

Ukuze ugweme isisiki ukuthi singasonti ngenxa yengcindezi eyeqile, zonke izingcezu zokusika ziklanyelwe ukuzungezisa ngokwewashi.

Lapho bonke abasiki sebeqedile, baphumelele ukuhlolwa kwebhalansi ukuze baqinisekise ukuthi akukho kungabaza mayelana nokubaleka. Ukuze uphinde uqinisekise ukuthi amathuluzi akhululekile ekujikeni nasekuphelelweni ngesikhathi sokusetshenziswa, sicela unake ukukhetha imishini nezinto zokusebenza namajakhethi amahle kakhulu.

Ijazi kufanele libe nobukhulu obufanele. Uma ibhantshi litholakala ligqwalile noma ligugile, ijakhethi ngeke likwazi ukubophela i-cutter ngendlela efanele nangendlela efanele. Sicela ushintshe ijakhethi ngokucaciswa okujwayelekile ngokushesha ukuze ugweme isisiki ekudlidlizeni kwesibambo se-athigh speed, ukundiza noma ukwephula ummese.

Ukufakwa kwe-cutter shank kufanele kuhambisane nemithetho ye-EU, futhi ukujula kokubopha kwe-cutter shank kufanele kube ngaphezu kwezikhathi ezi-3 ububanzi be-shank ukuze kugcinwe ububanzi obufanele bokucindezela kwe-shank.

I-Cutter enobubanzi obukhulu bangaphandle kufanele isethwe ngokuvumelana ne-tachometer elandelayo, futhi kancane kancane ithuthuke ukuze igcine isivinini esifana nesengaphambili. Ungayeki kusengaphambili ngesikhathi sokusika. Uma isisiki sibuthuntu, sicela ufake esisha esikhundleni saso.Ungaqhubeki nokusisebenzisa ukugwema ukuphuka kwamathuluzi kanye nezingozi ezihlobene nomsebenzi.Khetha isisiki esihambisanayo sezinto ezihlukene. Lapho usebenza futhi ucutshungulwa, sicela ugqoke izibuko zokuphepha futhi usunduze isibambo ngokuphepha. Lapho usebenzisa ama-ma-chines wedeskithophu kanye nemishini, udinga futhi ukusebenzisa izinto ezivimbela ukuphinda ubophe ukuze ugweme izingozi ezibangelwa ukuphindaphinda kwezinto zokusebenza ngesikhathi sokusika ngesivinini esikhulu.

| Ibhrendi | I-MSK | Ukupakisha | Ibhokisi lepulasitiki noma elinye |

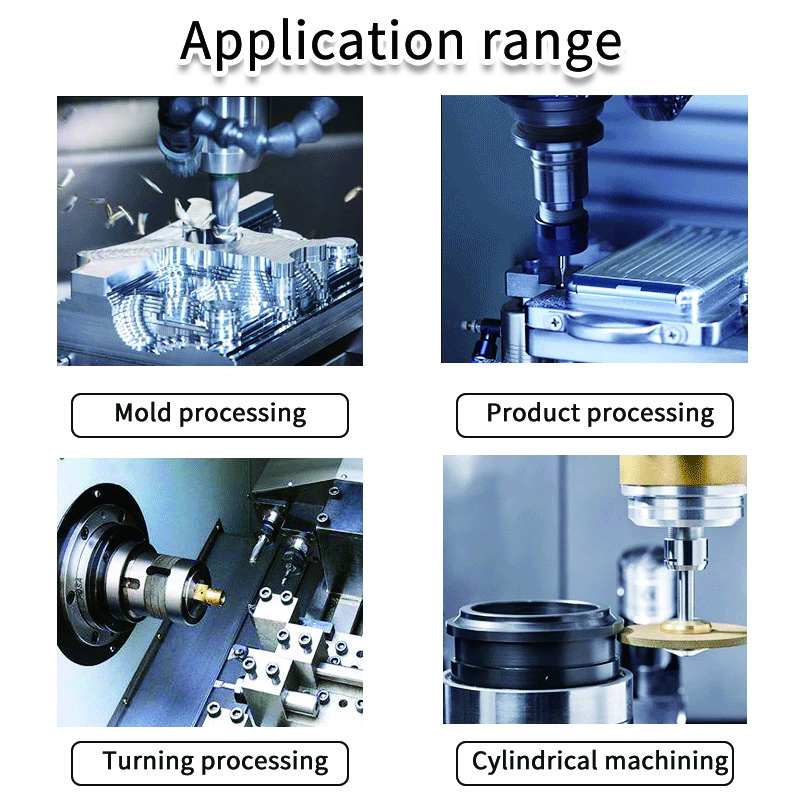

| Okubalulekile | I-aluminium, ingxube ye-aluminium | Ukusetshenziswa | I-Cnc Milling Machine Lathe |

| Usekelo olwenziwe ngokwezifiso | OEM, ODM | Uhlobo | End Mill |

Lokho amakhasimende akusho ngathi

FAQ

Q1: Singobani?

I-A1: I-MSK (Tianjin) Cutting Technology Co., Ltd. yasungulwa ngo-2015. Iyakhula futhi isidlulile e-Rheinland ISO 9001

Ngemishini yokukhiqiza ethuthukisiwe yomhlaba wonke efana nesikhungo sokugaya i-SACCKE esiphezulu se-axis emihlanu eJalimane, isikhungo sokuhlola amathuluzi e-ZOLLER e-axis six-axis eJalimane, namathuluzi omshini we-PALMARY e-Taiwan, izibophezele ekukhiqizeni amathuluzi e-CNC aphezulu, achwepheshe, asebenza kahle futhi ahlala isikhathi eside.

Q2: Ingabe uhweba inkampani noma umenzi?

A2: Singabakhiqizi bamathuluzi e-carbide.

Q3: Ungakwazi yini ukuthumela umkhiqizo kumthengisi wethu e-China?

I-A3: Yebo, uma unomdluliseli e-China, siyajabula ukuthumela imikhiqizo kuye.

Q4: Yimiphi imigomo yokukhokha engamukelwa?

A4: Ngokuvamile samukela i-T/T.

Q5: Ingabe uyawamukela oda OEM?

I-A5: Yebo, i-OEM nokwenza ngokwezifiso kuyatholakala, futhi sinikeza insizakalo yokuphrinta ilebula yangokwezifiso.

Q6: Kungani usikhethe?

1) Ukulawulwa kwezindleko - thenga imikhiqizo yekhwalithi ephezulu ngentengo efanelekile.

2) Impendulo esheshayo - kungakapheli amahora angama-48, ochwepheshe bazokunikeza izingcaphuno futhi baxazulule ukungabaza kwakho

cabangela.

3) Ikhwalithi ephezulu - inkampani ihlale ifakazela ngenhliziyo eqotho ukuthi imikhiqizo ehlinzekayo isezingeni eliphakeme elingu-100%, ukuze ungabi nazinkathazo.

4) Isevisi yangemuva kokuthengisa kanye nesiqondiso sobuchwepheshe - sizohlinzeka ngesevisi eyenziwe ngokwezifiso kanye nesiqondiso sobuchwepheshe ngokuya ngezidingo zakho.

Ama-collet chucks ngaphandle kwezikhala zedrayivu: isibambi sethuluzi okufanele ube nalo

Uma kuziwa ekwenzeni ukunemba, ukuba nesibambi samathuluzi esifanele kubalulekile. Omunye wamathuluzi anjalo yi-collet. Kulokhu okuthunyelwe kwebhulogi, sizohlola izinzuzo zama-collet chuck ngaphandle kwezikhala zokushayela, sigxile kubaphathi be-NBT ER 30 collet chuck.

I-collet isibambi samathuluzi esiqinisa ngokuvikelekile ithuluzi lokusika endaweni ngesikhathi sokusebenza komshini. Ukungabikho kwama-drive slots ku-collet chuck kunezinzuzo eziningana. Okokuqala, ngenxa yokuthi azikho izindawo zokushayela, ama-collets angakwazi ukufaka amathuluzi okusika amade, okuvumela ukusikeka okujulile nokwandisa umkhiqizo. Leli khono likwenza kube usizo ikakhulukazi ezimbonini ezifana ne-aerospace nezimoto lapho ukunemba kubaluleke khona.

Abanikazi be-NBT ER 30 collet bayikhethelo elidumile phakathi kochwepheshe bemboni yemishini. Ihlanganisa izinzuzo zekholethi engashayeli nokunemba kanye nokuguquguquka kwekholethi ye-ER. Abaphathi be-ER collet baziwa ngamandla abo okubamba ama-clamping kanye nokunemba okuphezulu. Nge-NBT ER 30 collet uthola zonke lezi zinzuzo ngesibambi esisodwa.

I-NBT ER 30 Collet Chuck Holders yakhelwe amathuluzi angama-cylindrical shank anobubanzi obungu-2-16mm. Ukwakhiwa kwayo okuhlangene kanye nokwakhiwa okuqinile kuqinisekisa ukuqina nokuqina okuphezulu ngesikhathi sokusebenza kwemishini. Umnikazi uhambisana nezinhlobonhlobo zemishini ye-CNC, okwenza kube ukukhetha okuguquguqukayo kwezinhlelo zokusebenza ezihlukahlukene zemishini.

Ngokungeziwe ekusebenzeni okuphakeme, i-NBT ER 30 collet chuck inikeza ukusetha okulula nokushintsha kwamathuluzi. Lokhu konga isikhathi esibalulekile sokusetha futhi kwandisa ukukhiqiza. I-collet chuck iza nesikrufu sokushintshwa kwethuluzi elisheshayo nelisebenza kahle, okuvumela opharetha ukuthi agxile emsebenzini owenzayo.

Sekukonke, amakholethi angenazo izikhala zedrayivu, njengezibambi zekholethi ze-NBT ER 30, angamathuluzi abalulekile omshini wokunemba. Ikhono layo lokwamukela amathuluzi okusika amade, ahlanganiswe namandla okubamba kanye nokunemba kwamakholethi e-ER, akwenza kube ukukhetha okuthandwayo kochwepheshe embonini. Noma ngabe usebenza ku-aerospace, izimoto, noma enye indawo yokwenza imishini enembayo, ukutshala imali ku-collet chuck yekhwalithi ephezulu ngaphandle kwezikhala zokushayela kungathuthukisa kakhulu ukusebenza kwakho komshini.