I-Tungsten Carbide Flow Drill Bit

INGCACISO YEMVELISO

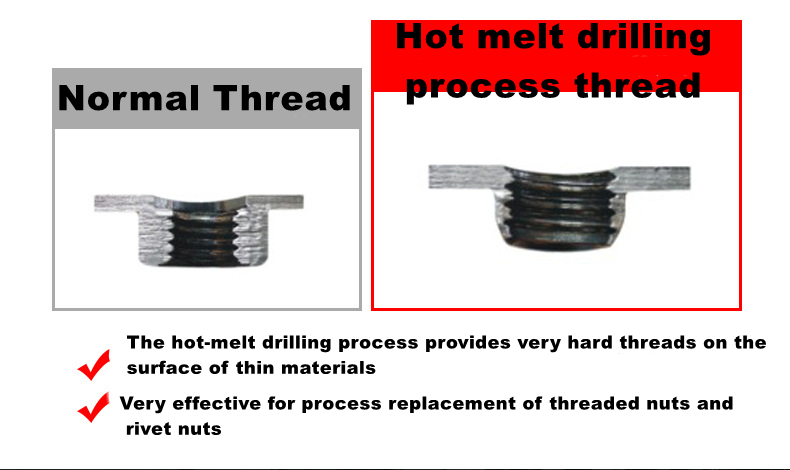

Umgaqo wokomba wokunyibilika oshushu

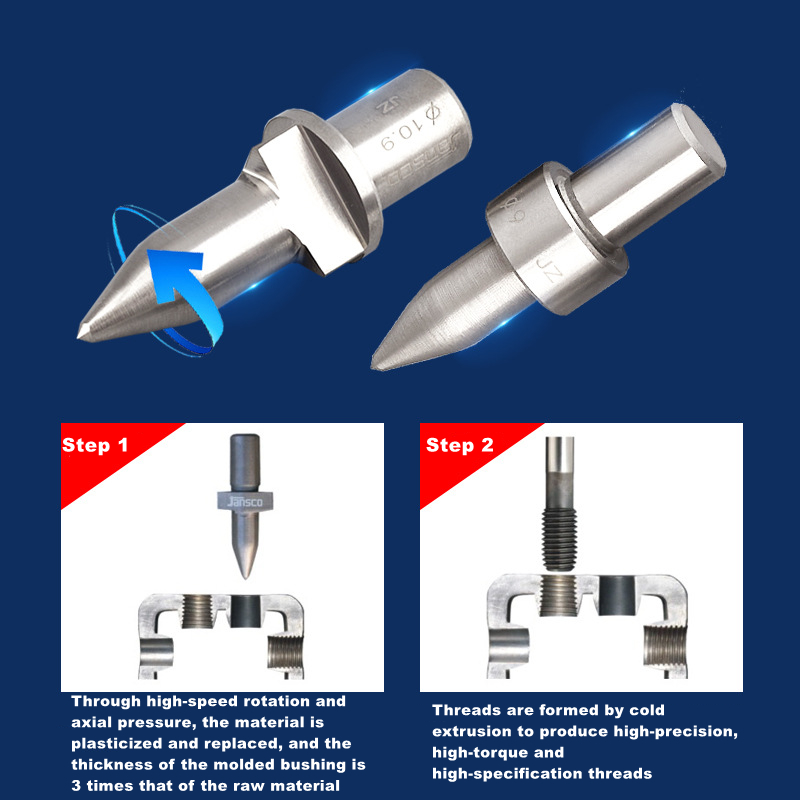

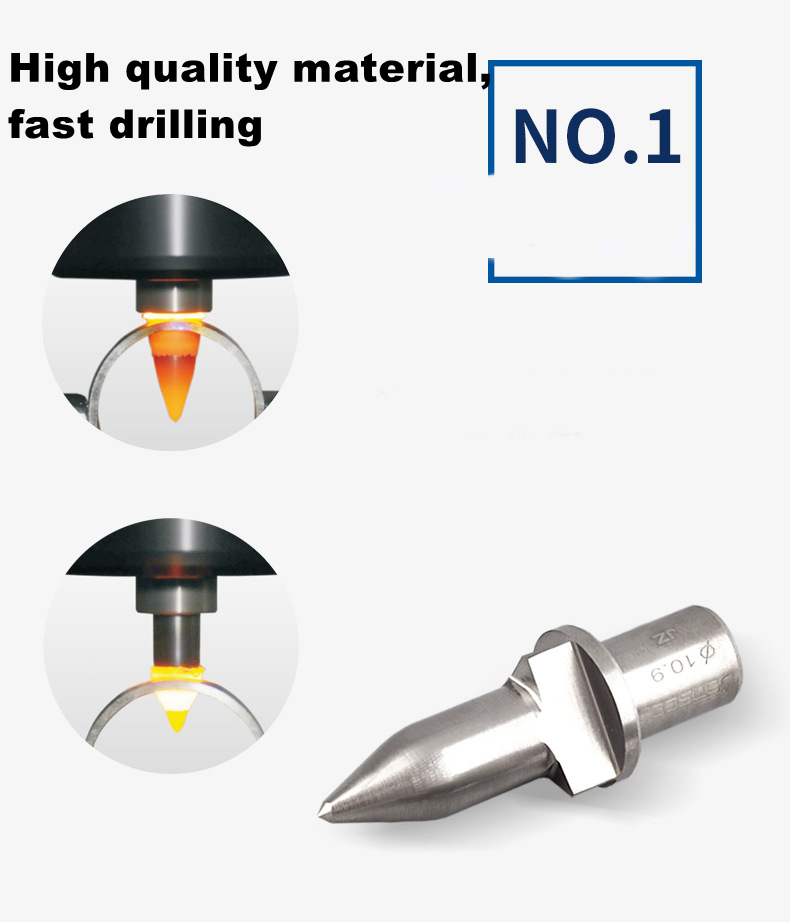

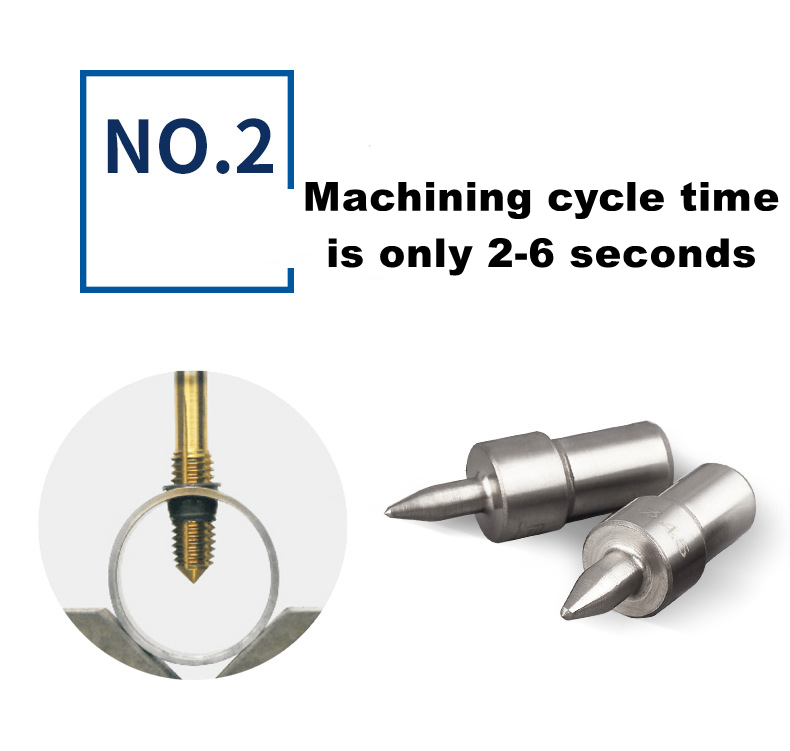

I-hot-melt drill ivelisa ubushushu ngokujikeleza kwesantya esiphezulu kunye ne-axial pressure friction ukwenza iplastiki kunye nokubuyisela izinto. Ngelo xesha, ibetha kwaye yenze i-bushing malunga namaxesha angama-3 ubukhulu bezinto eziluhlaza, kwaye ikhuphe kwaye icofe ngempompo ukuze iyenze kwizinto ezincinci. Ukuchaneka okuphezulu, imisonto ephezulu yamandla.

INGCEBISO YOKUSETYENZISWA KWIINDAWO YOKUSEBENZA

Isinyathelo sokuqala: ukufaka iplastiki kwizinto eziphathekayo ngokujikeleza ngesantya esiphezulu kunye noxinzelelo lwe-axial. Ubunzima be-bushing ebunjiweyo buphindwe kathathu kwizinto eziluhlaza.

Isinyathelo sesibini: intambo yenziwe ngokunyuka okubandayo ukuvelisa ukuchaneka okuphezulu, i-torque ephezulu kunye ne-high-specificatio.n imisonto

| Uphawu | MSK | Ukwaleka | No |

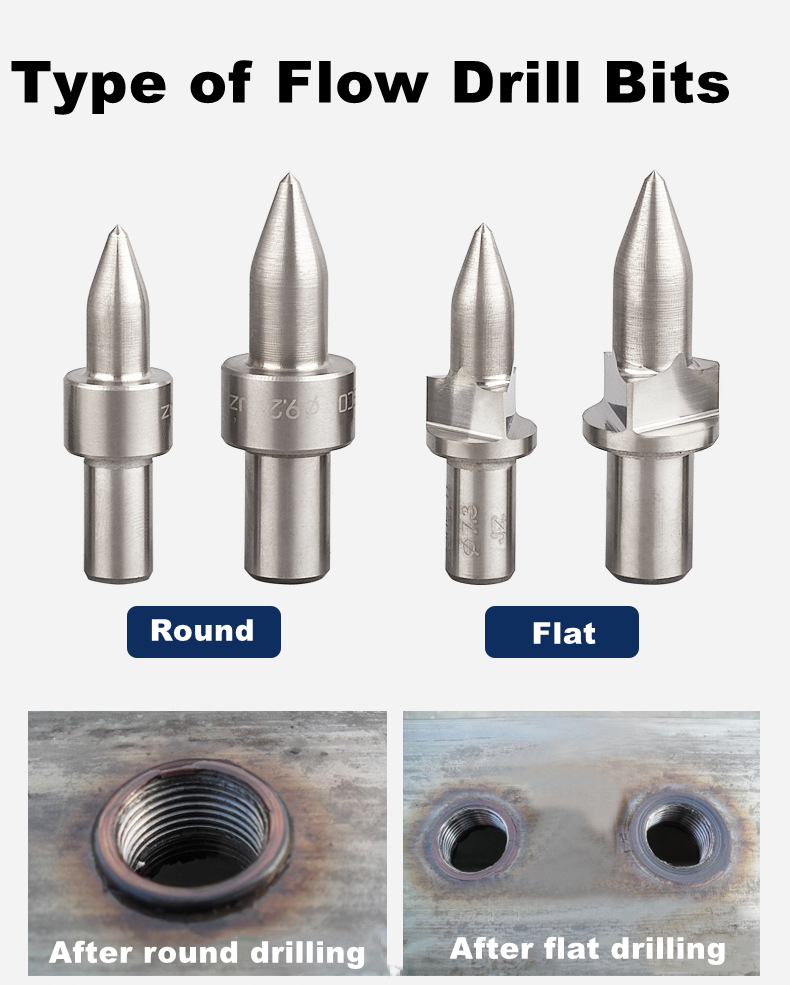

| Igama lemveliso | Iseti yeBit ye-Thermal Friction Drill | Uhlobo | Uhlobo oluMcaba/ oluRound |

| Izinto eziphathekayo | Carbide Tungsten | Sebenzisa | Ukugrumba |

UMBONO

Izilumkiso zokusetyenziswa kwe-hot melt drills:

1. Isixhobo sokusebenza: i-drill-melt drill ilungele ukusetyenzwa kwezixhobo ezahlukeneyo zetsimbi kunye nobubanzi be-1.8-32mm kunye nobukhulu bodonga lwe-0.8-4mm, njengentsimbi, intsimbi ethambileyo, insimbi engenasici, i-titanium, i-aluminiyam, ubhedu, ubhedu, ubhedu (umxholo we-Zn ongaphantsi kwe-40%), i-aluminium engaphantsi kwe-aluminiyamu enzima, njl. bufutshane ubomi be-hot melt drill.

2. I-Hot-melt paste: Xa i-hot-melt drill isebenza, ubushushu obuphezulu obungaphezu kwama-600 degrees iveliswa ngoko nangoko. I-paste ekhethekileyo ye-hot-melt inokwandisa ubomi benkonzo ye-hot melt drill, iphucule umgangatho womgangatho wangaphakathi we-cylinder, kwaye ivelise i-edge edge shape ecocekileyo neyanelisayo. Kucetyiswa ukuba ungeze inani elincinci le-hot melt paste kwisixhobo kuzo zonke izimbobo ezi-2-5 ezigrunjwe kwintsimbi yekhabhoni eqhelekileyo; kwi-workpieces yensimbi engenasici, kumngxuma ngamnye owenziweyo, yongeza i-hot melt paste ngesandla; ukuqina kunye nokuqina kwemathiriyeli, kokukhona kunyuka ukuphindaphindeka kokongeza.

3. I-shank kunye ne-chuck ye-hot melt drill: Ukuba akukho sinki ekhethekileyo yokufudumala, sebenzisa umoya ocinezelweyo ukupholisa.

4. Izixhobo zomatshini wokubhoboza: ixesha elide oomatshini bokugaya abahlukeneyo, oomatshini bokugaya kunye namaziko omatshini anesantya esifanelekileyo kunye namandla afanelekile ukugaya i-hot-melt; Ubunzima bezinto eziphathekayo kunye nokwahlukana kwezinto ngokwazo zonke zichaphazela ukuzimisela kwesantya sokujikeleza.

5. Imingxuma eyenziwe kwangaphambili: Ngokubhobhoza umngxuma omncinci wokuqala, i-workpiece deformation inokuphetshwa. Imingxunya eyenziwe ngaphambili inokunciphisa amandla e-axial kunye nokuphakama kwe-cylinder, kwaye inokuvelisa i-catterer edge kwisiphelo esisezantsi se-cylinder ukuphepha ukugoba ukuguqulwa kwezinto ezinqabileyo ezinqabileyo (ngaphantsi kwe-1.5mm).

6. Xa ucofa, sebenzisa ioli yokucofa: kucetyiswa ukuba kusetyenziswe iipompo ze-extrusion, ezingenziwanga ngokusika kodwa ngokukhupha, ngoko zinamandla aphezulu kunye nexabiso le-torsion. Kwakhona kunokwenzeka ukusebenzisa iimpompo zokusika eziqhelekileyo, kodwa kulula ukusika i-cylinder, kwaye ububanzi be-hot-melt drill iyahluka kwaye kufuneka yenziwe ngokwahlukileyo.

7. Ukugcinwa kwe-hot-melt drill: Emva kokuba i-hot-melt drill isetyenziswe ixesha elithile, umphezulu uya kunxitywa, kunye ne-hot-melt paste okanye ukungcola komsebenzi kuya kuqhotyoshelwe kumzimba wokusika. Gqoka i-drill eshushu yokunyibilika kwi-chuck yeleyile okanye umatshini wokusila, kwaye uyigaye ngentlama erhawukileyo. Musa ukunikela ingqalelo kukhuseleko.