Carbide T-slot End Mill Cutter Fresas Para Ranura Cuadros Tipo T

INGCACISO YEMVELISO

Kumsebenzi ophezulu weT-slot milling kunye namazinga aphezulu okutya kunye nobunzulu bokusika. Kwakhona ifanelekile kwi-groove emazantsi machining kwizicelo zokusila ezijikelezayo. Ufakelo olufakelweyo olufakelweyo olunesalathisi esinesiqinisekiso sokususwa kwetshiphu sidityaniswe nokusebenza okuphezulu ngamaxesha onke.

Uyilo olukhethekileyo oluphezulu lwe-helical groove, kunye noyilo olufanelekileyo lokuphepha umoya, luyenze ibe nendawo enkulu yokususa i-chip, eyenza ukususwa kwe-chip kube lula ngexesha lokusika.

Iimpawu eziphambili:

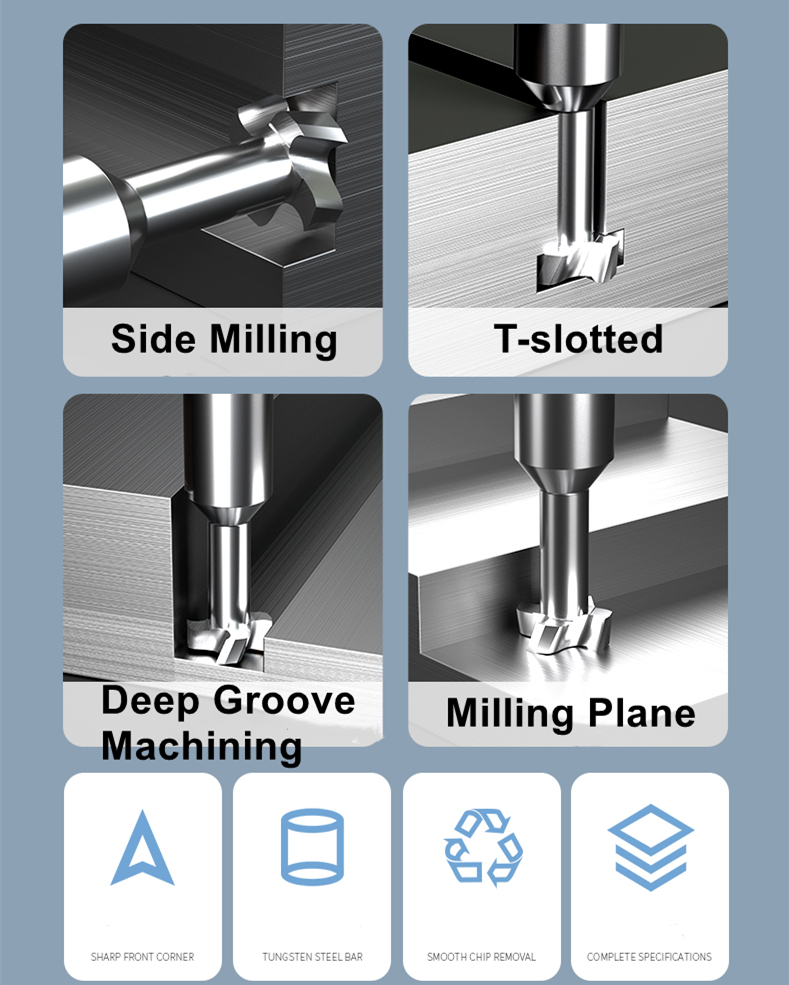

Sisixhobo esikhethekileyo sokusetyenzwa kwe-T-slots. Emva kokuba i-grooves ethe tye i-milled, i-T-slots ngokuchaneka okufunekayo inokugatywa ngexesha elinye. Ukuphela komphetho we-milling cutter ine-angle yokusika efanelekileyo. ukuchaneka okuphezulu kunye neglossier.

I-T-slot milling cutter (ekwaziwa ngokuba yi-T-slot milling cutter, i-waist slot milling cutter)

Iimpawu ze-T-slot milling cutter: i-square grooves eyahlukeneyo, i-grooves circular, i-grooves ekhethekileyo, njl., Iphucula kakhulu ukusebenza kakuhle kwimveliso;

I-T-slot milling cutter material: i-carbide, i-V-welding, i-powder metallurgy, i-welding alloy inserts, njl.;

Ukugquma kwe-T-slot milling cutter: ukugquma kunokuzikhethela, kwaye ukugquma kuchazwe ngokwemiqathango yokusebenza kwezinto zemveliso;

Amashishini aphambili e-T-slot milling cutter: iinxalenye zemoto, izinto zombane, ezonyango, ezomoya, oomatshini bokwakha kunye nezinye iindawo ezininzi;

I-T-slot milling cutter processing materials: iintsimbi ezingenayo i-ferrous (i-aluminium alloy, i-copper), i-iron cast, i-alloy steel, i-carbon steel low, i-high-hardness steel, i-stainless steel, kunye nezixhobo ezahlukeneyo ezinzima kumatshini;

INGCEBISO YOKUSETYENZISWA KWIINDAWO YOKUSEBENZA

1. Imivalo yentsimbi ye-tungsten evela kumazwe angaphandle ikhethiweyo, enobunzima obuphezulu kunye nokumelana nokunxiba, okubukhali kwaye akukho lula kwiimela ezimfutshane, kunye nobomi benkonzo ende.

2. Uyilo lwe-Cutter edge, ubugcisa obujikelezileyo, ukhetho oluhle kakhulu lwezinto eziphathekayo, kunye noyilo olukhulu lokusika luphucula kakhulu ukugudisa.

3. Incakuba ebukhali. Umgca wokusika ubukhali, okwenza ukusika kube lula, kwaye i-anti-vibration design of the cut edge inokuphucula ngokufanelekileyo ukuzinza kokucubungula kunye nomgangatho womhlaba.

4. Uyilo lwe-chamfer, ubungakanani obuqhelekileyo be-chamfer, i-chamfer ye-45 degree, i-contour ejikelezayo kunye negudileyo, okwenza kube lula ukuyifaka.

| Uphawu | MSK | Izinto eziphathekayo | Die intsimbi; Jula i-ayini; intsimbi yekhabhoni; intsimbi yengxubevange |

| Igama lemveliso | T-slot End Mill Cutter | Iphakheji | Ibhokisi yePlastiki |

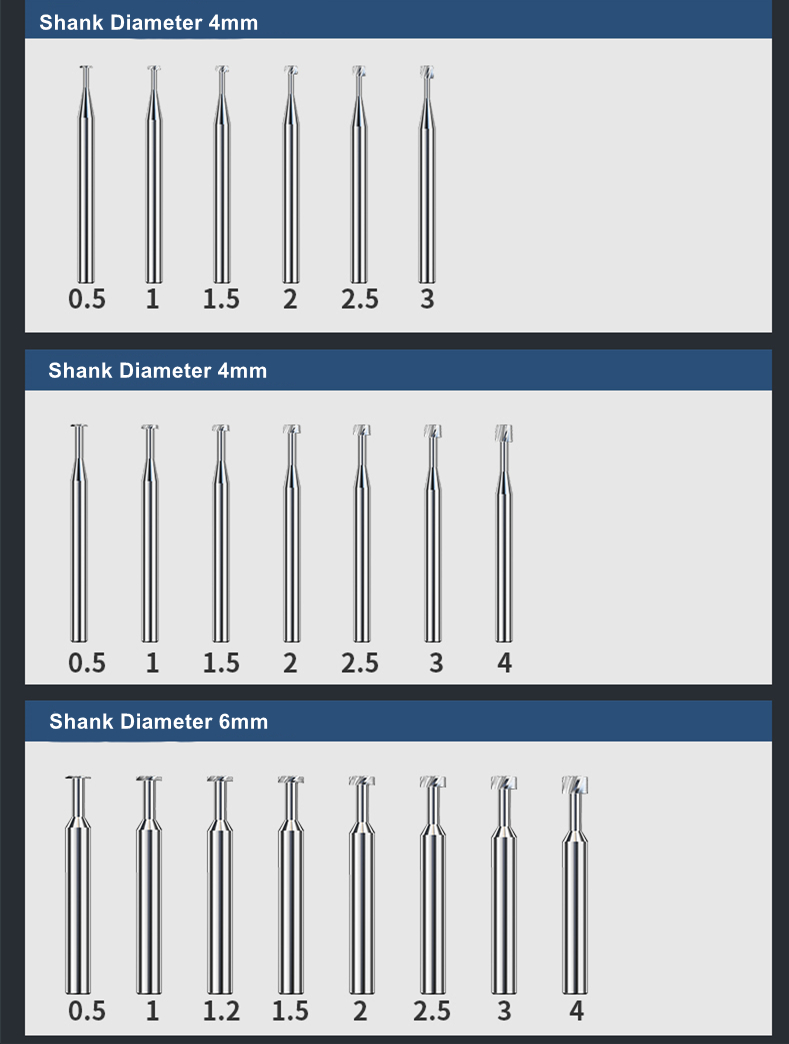

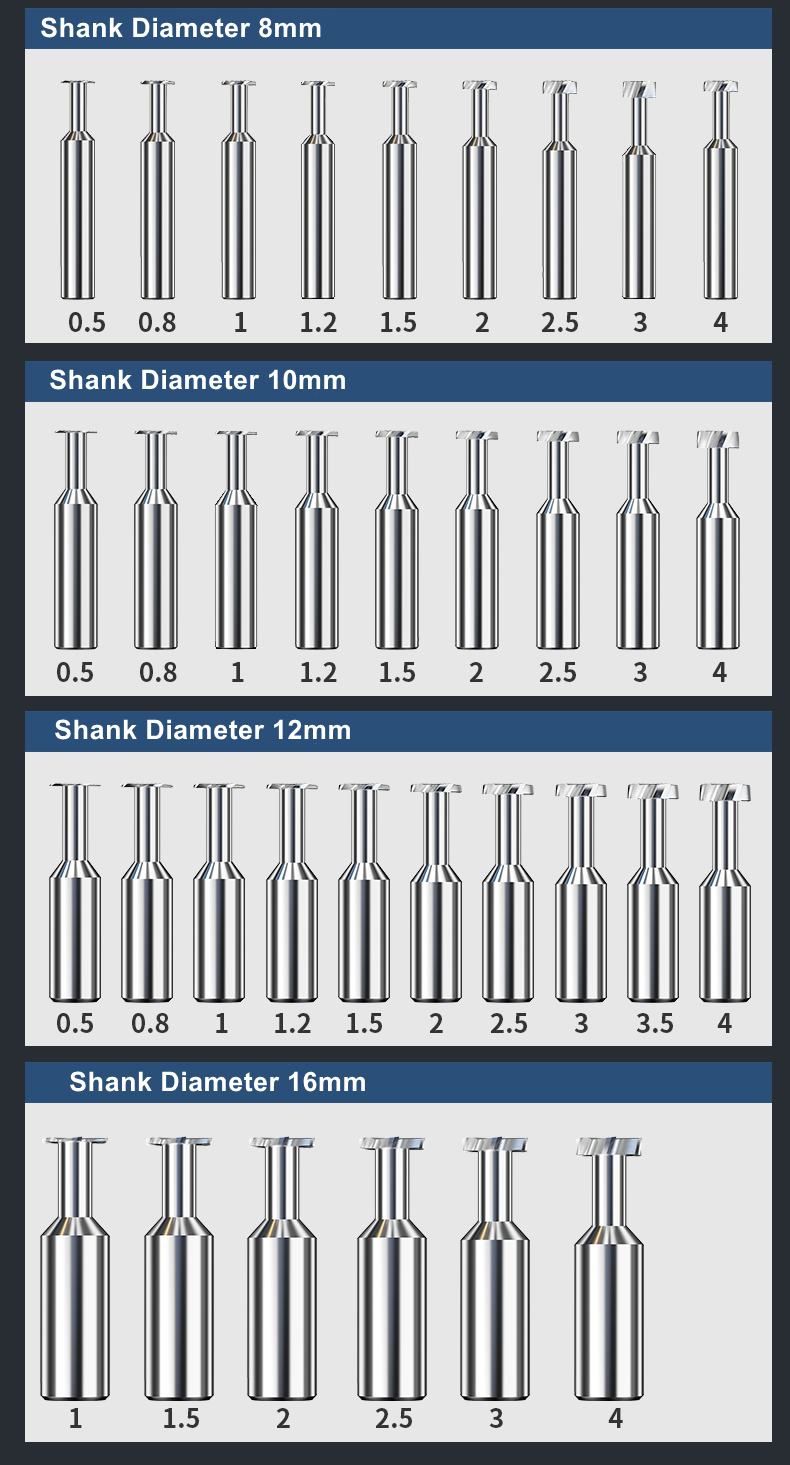

Imifanekiso eneenkcukacha