Njengesixhobo esiqhelekileyo sokulungisa imisonto yangaphakathi, iimpompo zinokwahlulwa zibe ziimpompo ze-spiral groove, iimpompo zokuthambekela komphetho, iimpompo zegroove ezithe ngqo kunye neetephu zentambo yombhobho ngokwemilo yazo, kwaye zinokwahlulwa zibe ziimpompo zezandla kunye neetephu zoomatshini ngokwendawo yokusetyenziswa. Yahlulahlulwe ngokwemetric, yaseMelika, kunye neetephu zasebukhosini. Ngaba uqhelene nabo bonke?

01 Cofa ulwahlulo

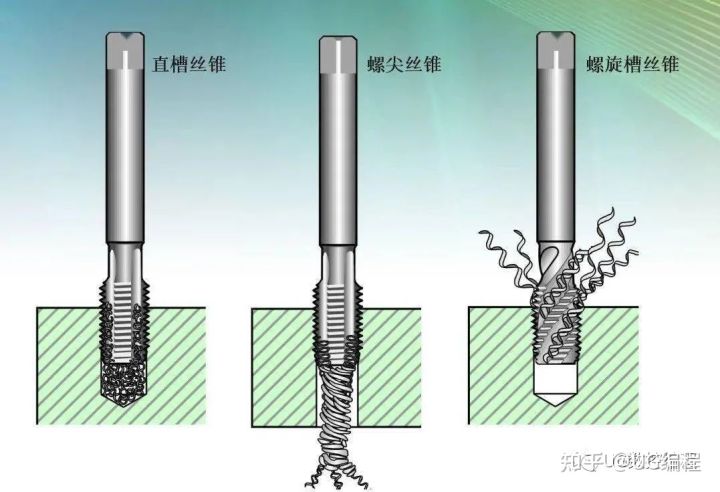

(1) Ukusika iimpompo

1) Impompo yefluti ethe ngqo: isetyenziselwa ukucutshungulwa kwemingxuma kunye nemingxuma eyimfama, iitshiphu zentsimbi zikhona kwi-tap groove, umgangatho wentambo esetyenzisiweyo ayiphezulu, kwaye isetyenziswa ngokuqhelekileyo ukusetyenzwa kwezinto ezimfutshane ze-chip, ezifana nentsimbi engwevu, njl.

2) Impompo ye-Spiral groove: isetyenziselwa ukusetyenzwa komngxuma oyimfama ngobunzulu bomngxuma obungaphantsi okanye obulingana ne-3D, iifayili zentsimbi zikhutshelwa ecaleni kwe-spiral groove, kwaye umgangatho womphezulu wentambo uphezulu.

I-10 ~ 20 ° itephu ye-engile ye-helix inokucubungula ubunzulu bomsonto obungaphantsi okanye obulingana no-2D;

I-28 ~ 40 ° itephu ye-angle ye-helix iyakwazi ukucubungula ubunzulu bentambo ngaphantsi okanye ilingana ne-3D;

I-50 ° i-helix angle tap ingakwazi ukucubungula ubunzulu bentambo ngaphantsi okanye ilingane ne-3.5D (imeko ekhethekileyo yokusebenza i-4D).

Kwezinye iimeko (izinto eziqinileyo, i-pitch enkulu, njl.njl.), Ukuze ufumane amandla angcono amazinyo, i-helical flute tap isetyenziselwa umatshini ngokusebenzisa imingxuma.

3) I-Spiral point tap: idla ngokusetyenziswa kuphela kwimingxuma, umlinganiselo wobude bobude ungafikelela kwi-3D ~ 3.5D, iitshiphusi zentsimbi zikhutshelwa ezantsi, i-torque yokusika incinci, kwaye umgangatho womphezulu womsonto owenziwe ngoomatshini uphezulu, okwaziwa ngokuba yi-edge angle tap okanye i-apex tap.

Xa usika, kuyimfuneko ukuqinisekisa ukuba zonke iindawo zokusika zingenwe, ngaphandle koko ukutshiza kwamazinyo kuya kwenzeka.

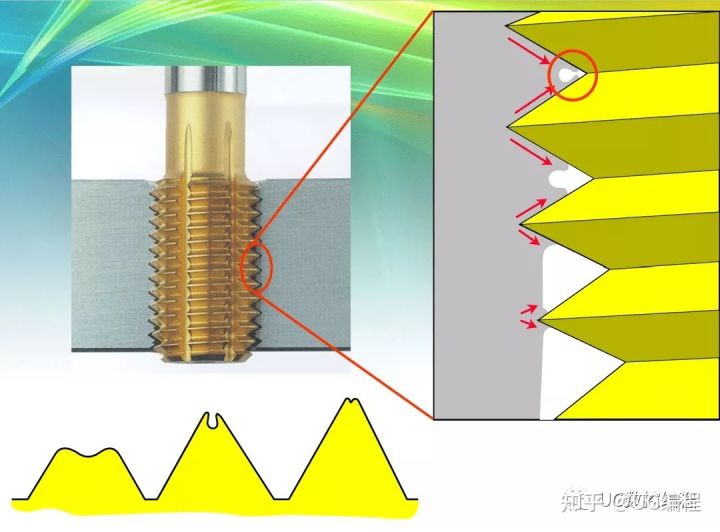

(2) Impompo yokukhupha

Ingasetyenziselwa ukusetyenzwa kwemingxuma kunye nemingxuma eyimfama, kwaye imilo yezinyo yenziwe ngokuguqulwa kweplastiki yezinto eziphathekayo, ezinokusetyenziswa kuphela ukusetyenzwa kwezinto zeplastiki.

Iimpawu zayo eziphambili:

1) Sebenzisa i-deformation yeplastiki ye-workpiece ukucubungula intambo;

2) Ummandla we-cross-sectional we-tap mkhulu, amandla aphezulu, kwaye akulula ukuphula;

I-3) Isantya sokusika sinokuphakama kunompompo wokusika, kwaye imveliso iphinda inyuke ngokufanelekileyo;

I-4) Ngenxa yenkqubo ye-extrusion ebandayo, iipropathi ze-mechanical of the processed thread surface ziphuculwe, uburhabaxa bomhlaba buphezulu, kwaye ukuqina kwentambo, ukuxhathisa ukugqoka kunye nokuxhatshazwa kwe-corrosion kuphuculwe;

5) I-chipless machining.

Iziphene zayo zezi:

1) ingasetyenziselwa kuphela ukucubungula izinto zeplastiki;

2) Iindleko zokuvelisa ziphezulu.

Kukho iifom ezimbini zesakhiwo:

I-1) Iimpompo zokukhupha ngaphandle kwee-oyile zisetyenziselwa kuphela ukucwangciswa okuthe nkqo kwemingxuma eyimfama;

2) Iimpompo ze-Extrusion kunye ne-oil grooves zifanelekile kuzo zonke iimeko zokusebenza, kodwa ngokuqhelekileyo iimpompo ezincinci ze-diameter azenzi i-oil grooves ngenxa yobunzima bokuvelisa.

(1) Imilinganiselo

1) Ubude obupheleleyo: Nika ingqalelo kwezinye iimeko zokusebenza ezifuna ukwandiswa okukhethekileyo

2) Ubude beslot: dlula

3) I-Shank: Okwangoku, imigangatho ye-shank eqhelekileyo yi-DIN (371/374/376), i-ANSI, i-JIS, i-ISO, njl.

(2) Inxalenye enemisonto

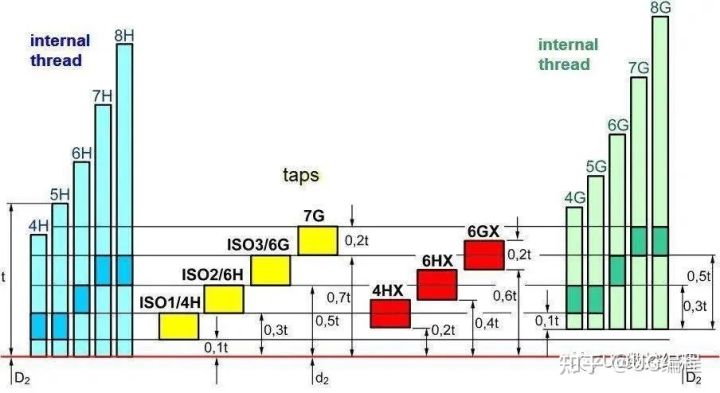

1) Ukuchaneka: Ikhethwe ngumgangatho othile wentambo. Inqanaba le-ISO1/2/3 le-metric thread lilingana nomgangatho wesizwe we-H1/2/3, kodwa kuyimfuneko ukunikela ingqalelo kwimigangatho yolawulo lwangaphakathi lomenzi.

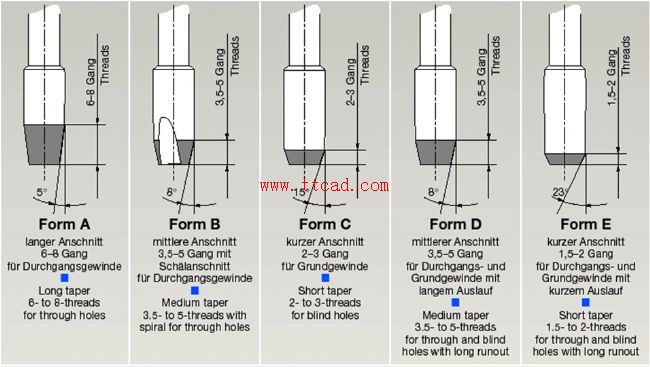

2) Umpompo wokusika: Inxalenye yokusika yempompo yenze inxalenye yepateni emiselweyo. Ngokubanzi, okukhona impompo yokusika inde, kokukhona ubomi bempompo bungcono.

I-3) Amazinyo okulungisa: Idlala indima yokuncedisa kunye nokulungiswa, ngokukodwa kwimeko engazinzanga yenkqubo yokucofa, amazinyo okulungisa amazinyo, ngakumbi ukuchasana nokubetha.

(3) Iifluti zetshiphu

1. Uhlobo lwe-Groove: Ichaphazela ukubunjwa kunye nokukhutshwa kweefayili zensimbi, ngokuqhelekileyo imfihlo yangaphakathi yomenzi ngamnye.

2. I-angle ye-Rake kunye ne-angle yokunceda: xa umpompo unyuswa, umpompo uba bukhali, onokuthi unciphise kakhulu ukuchasana kokusika, kodwa amandla kunye nokuzinza kwezinyo kwehla, kwaye i-angle yokunceda i-angle yokunceda.

3. Inani lee-grooves: inani le-grooves liyakhula kwaye inani leemida zokusika liyenyuka, elinokuphucula ngokufanelekileyo ubomi bompompo; kodwa iyakucinezela indawo yokususa itshiphu, engalunganga ekususweni kwetshiphu.

03 Thepha imathiriyeli kunye nokwaleka

(1) Izinto zempompo

1) Insimbi yesixhobo: Isetyenziswa kakhulu kwiimpompo ze-incisor zezandla, ezingaqhelekanga ngoku.

2) I-Cobalt-free-speed steel high-speed steel: Okwangoku, isetyenziswa ngokubanzi njengezinto zompompo, ezifana ne-M2 (W6Mo5Cr4V2, 6542), M3, njl., kunye nekhowudi yokumakisha yi-HSS.

3) I-Cobalt ene-high-speed steel: okwangoku isetyenziswa ngokubanzi njengezixhobo zompompo, ezifana ne-M35, i-M42, njl., ikhowudi yokumakisha yi-HSS-E.

I-4) I-metallurgy ye-powder high-speed steel: Isetyenziswe njengempompo ephezulu yokusebenza, ukusebenza kuphuculwe kakhulu xa kuthelekiswa nezi zimbini zingasentla. Iindlela zokuqamba zomenzi ngamnye zikwahluke, kwaye ikhowudi yokumakisha yi-HSS-E-PM.

I-5) Izixhobo ze-carbide ezenziwe ngesamente: ngokuqhelekileyo zisebenzisa amasuntswana e-ultra-fine kunye namabakala amahle okuqina, asetyenziswa kakhulu ukwenza iimpompo zeflute ezithe tye ukusetyenzwa kwezixhobo ezimfutshane ze-chip, ezifana nentsimbi engwevu, i-aluminium ephezulu yesilicon, njl.

Iimpompo zixhomekeke kakhulu kwizinto eziphathekayo, kwaye ukukhethwa kwezinto ezilungileyo kunokwandisa ngakumbi iiparitha zesakhiwo seempompo, zizenze zilungele ukusebenza kakuhle kunye neemeko zokusebenza ezinzima, kwaye kwangaxeshanye zinobomi benkonzo ephezulu. Okwangoku, abavelisi beempompo ezinkulu banemizi-mveliso yabo yezinto eziphathekayo okanye iifomyula eziphathekayo. Ngexesha elifanayo, ngenxa yeengxaki zemithombo ye-cobalt kunye namaxabiso, iintsimbi ezintsha ezingenayo i-cobalt-high-performance high-speed steels nazo ziphumile.

(2) Ukugquma itephu

1) I-Steam oxidation: Itephu ifakwe kumphunga wamanzi wobushushu obuphezulu ukwenza ifilimu ye-oxide phezu komhlaba, ene-adsorption elungileyo kwisipholisi, inokunciphisa ukukhuhlana, kwaye ithintele impompo kunye nezinto ezinokuthi zisikwe. Ifanelekile ukwenza intsimbi ethambileyo.

2) unyango Nitriding: Umphezulu impompo nitrided ukwenza umaleko umphezulu lukhuni, nto leyo ilungele machining cast iron, cast aluminiyam kunye nezinye izinto ezinxibe izixhobo ezinkulu.

3) Umphunga + Nitriding: Dibanisa iingenelo kwezi zimbini zingasentla.

I-4) I-TiN: i-Tin yegolide etyheli, enobulukhuni obuhle bokugquma kunye nokuthambisa, kunye nokuncamathela okulungileyo, okufanelekile ukusetyenzwa kwezinto ezininzi.

I-5) I-TiCN: i-blue-gray coating kunye nobunzima malunga ne-3000HV kunye nokumelana nokushisa kwe-400 ° C.

I-6) i-TiN + TiCN: i-coat emnyama emnyama, enobunzima obuhle bokugquma kunye nokuthambisa, ilungele ukusetyenzwa kwezinto ezininzi.

I-7) I-TiAlN: i-blue-gray coating, ubunzima be-3300HV, ukumelana nobushushu ukuya kwi-900 ° C, ingasetyenziselwa umatshini we-high-speed.

I-8) I-CrN: I-coating yesilivere-ngwevu, intsebenzo egqwesileyo yokuthambisa, eyona nto isetyenziselwa ukusetyenzwa kweentsimbi ezingenayo i-ferrous.

Impembelelo yokugquma kompompo ekusebenzeni kompompo ibonakala kakhulu, kodwa okwangoku, abaninzi abavelisi kunye nabavelisi beengubo bayasebenzisana ukuze bafunde iingubo ezikhethekileyo.

04 Elements Ezichaphazela Ukucofa

(1) Izixhobo zokucofa

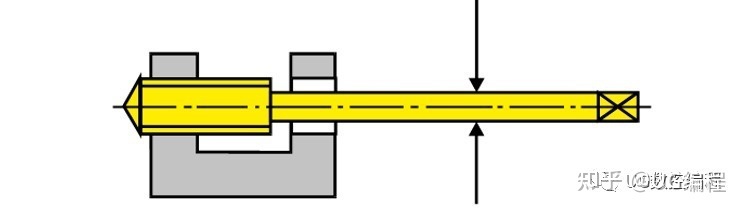

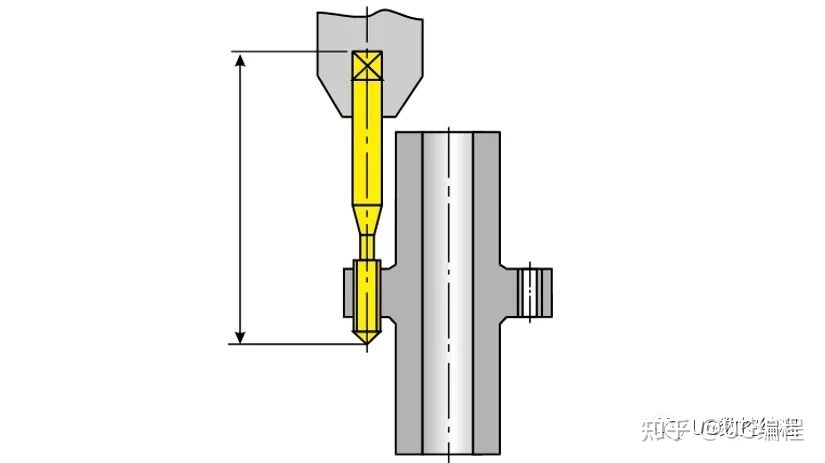

I-1) Isixhobo somatshini: Inokwahlulwa ngokweendlela ezithe nkqo nezithe tye. Ukucofa, ukusetyenzwa ngokuthe nkqo kungcono kunokulungiswa okuthe tye. Xa ukupholisa kwangaphandle kwenziwa kwi-horizontal processing, kuyimfuneko ukuqwalasela ukuba ngaba ukupholisa kwanele.

2) Umphathi wesixhobo sokucofa: Kucetyiswa ukuba usebenzise isixhobo esikhethekileyo sokucofa isixhobo sokucofa. Isixhobo somatshini siqinile kwaye sizinzile, kwaye i-synchronous tool holder ikhethwayo. Ngokuchasene noko, isibambi sesixhobo sokucofa esine-axial/radial kufuneka sisetyenziswe kangangoko. . Ngaphandle kweempompo zedayamitha ezincinci (

(2) Izinto zokusebenza

1) Izinto kunye nokuqina kwesixhobo sokusebenza: ukuqina kwesixhobo sokusebenza kufuneka kufane, kwaye akukhuthazwa ngokubanzi ukusebenzisa itephu ukucubungula izixhobo zokusebenza ezidlula i-HRC42.

2) Ukucofa umngxuma ongezantsi: isakhiwo somngxuma osezantsi, khetha i-drill bit efanelekileyo; ukuchaneka kobungakanani bomngxuma ongezantsi; umgangatho wodonga lomngxuma ongezantsi.

(3) Iiparamitha zokucubungula

I-1) Isantya sokujikeleza: Isiseko sesantya esinikiweyo luhlobo lwempompo, izinto eziphathekayo, izinto eziza kucutshungulwa kunye nobunzima, umgangatho wezixhobo zokucofa, njl.

Ngokuqhelekileyo ikhethwe ngokweeparamitha ezinikwe ngumenzi wempompo, isantya kufuneka sincitshiswe phantsi kwezi meko zilandelayo:

- ukuqina komatshini; ukuphuma kwempompo enkulu; ukupholisa okungonelanga;

- izinto ezingalinganiyo okanye ubunzima kwindawo yokucofa, njengamalungu e-solder;

- impompo yandiswa, okanye intonga yokwandisa isetyenziswe;

- Recumbent plus, ukupholisa ngaphandle;

- Ukusebenza ngesandla, okufana ne-bench drill, i-radial drill, njl.;

2) Ukutya: ukucofa okuqinileyo, ukondla = i-1 thread pitch / revolution.

Kwimeko yokucofa okuguquguqukayo kunye neenguqu ezaneleyo zembuyekezo ye-shank:

Ukutya = (0.95-0.98) pitches / rev.

05 Iingcebiso zokukhetha iimpompo

(1) Ukunyamezela iimpompo zamabakala ahlukeneyo achanekileyo

Isiseko sokhetho: ibakala lokuchaneka kwempompo alinakukhethwa kwaye limiselwe kuphela ngokwebakala lokuchaneka komsonto owenziwa ngoomatshini.

1) Izinto kunye nobunzima bomsebenzi oza kuqhutyelwa phambili;

2) Izixhobo zokucofa (ezifana neemeko zesixhobo somatshini, izixhobo zokubamba izixhobo, amakhonkco okupholisa, njl.);

3) Ukuchaneka kunye nempazamo yokwenziwa kwempompo ngokwayo.

Ngokomzekelo, xa kusetyenzwa imicu ye-6H, xa kusetyenzwa iinxalenye zentsimbi, iimpompo ezichanekileyo ze-6H zingasetyenziswa; xa kusetyenzwa intsimbi engwevu, kuba i-diameter ephakathi yeetephu inxiba ngokukhawuleza kwaye ukwandiswa kwemingxuma ye-screw kuncinci, kungcono ukusebenzisa iimpompo ezichanekileyo ze-6HX. Thepha, ubomi buya kuba ngcono.

Inqaku malunga nokuchaneka kweempompo zaseJapan:

I-1) I-OSG yokusika itephu isebenzisa inkqubo ye-OH echanekileyo, eyahlukileyo kwi-ISO standard. Inkqubo yokuchaneka kwe-OH inyanzelisa ububanzi bebhendi yonke yokunyamezela ukuqala ukusuka kumda ophantsi, kwaye yonke i-0.02mm isetyenziswe njengebakala elichanekileyo, elibizwa ngokuba yi-OH1, OH2, OH3, njl.;

2) Itephu ye-extrusion ye-OSG isebenzisa inkqubo yokuchaneka kwe-RH. Inkqubo yokuchaneka kwe-RH inyanzelisa ububanzi bebhendi yonke yokunyamezela ukuqala ukusuka kumda ophantsi, kwaye nganye i-0.0127mm isetyenziswe njengezinga lokuchaneka, elibizwa ngokuba ngu-RH1, RH2, RH3, njl.

Ke ngoko, xa usebenzisa iitephu ezichanekileyo ze-ISO ukufaka indawo yeempompo ezichanekileyo ze-OH, ayinakuthathwa ngokulula ukuba i-6H iphantse ilingane ne-OH3 okanye ibakala le-OH4. Kufuneka kugqitywe ngokuguqulwa, okanye ngokwemeko yangempela yomthengi.

(2) Imilinganiselo yempompo

1) Ezona zisetyenziswa kakhulu zi-DIN, ANSI, ISO, JIS, njl.;

2) Kuvunyelwe ukukhetha ubude obufanelekileyo obupheleleyo, ubude be-blade kunye nobukhulu be-shank ngokweemfuno ezahlukeneyo zokucubungula abathengi okanye iimeko ezikhoyo;

3) Ukuphazamiseka ngexesha lokucubungula;

(3) Izinto ezi-6 ezisisiseko zokukhetha impompo

1) Uhlobo lwentambo yokucubungula, i-metric, intshi, i-American, njl.;

2) Uhlobo lomngxuma ongezantsi ophothiweyo, ngomngxuma okanye umngxuma oyimfama;

3) Izinto kunye nobunzima bomsebenzi oza kuqhutyelwa phambili;

4) Ubunzulu bomtya opheleleyo we-workpiece kunye nobunzulu bomngxuma ophantsi;

5) Ukuchaneka okufunekayo kwentambo yomsebenzi;

6) Umgangatho wemilo yempompo

Ixesha lokuposa: Jul-20-2022