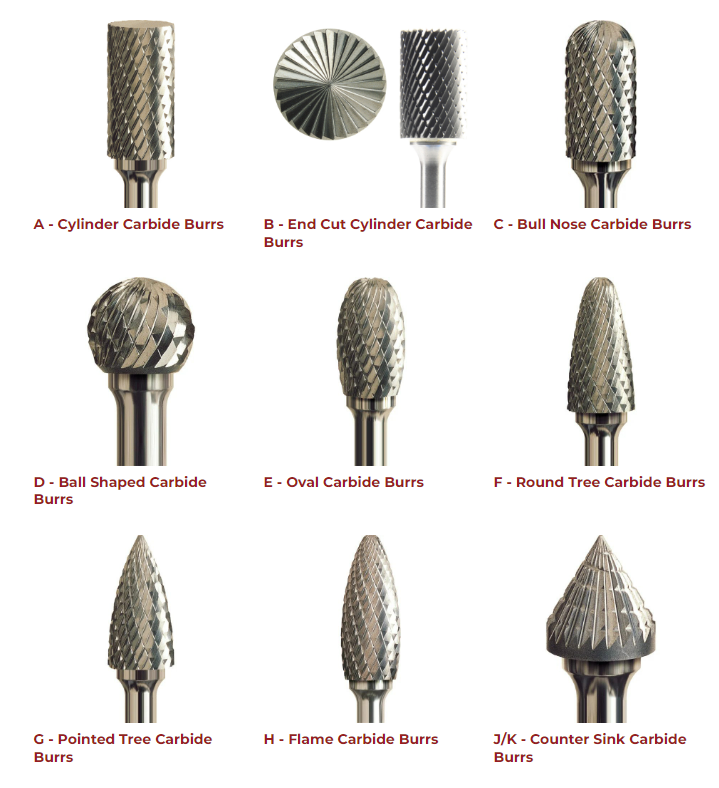

Imilo enqamlezileyo yetungsten intsimbi yokusilaiibharskufuneka zikhethwe ngokwemilo yamalungu aza kufakwa efayilini, ukuze iimilo zamacandelo amabini zilungelelaniswe. Xa ufaka i-arc surface yangaphakathi, khetha i-semi-circular okanye i-carbide bur ejikelezayo; xa ufaka umphezulu wekona yangaphakathi, khetha ifayile engunxantathu; xa ufaka i-right-angle surface yangaphakathi, ungakhetha ifayile ethe tyaba okanye isikwere sokukrola. Xa ukhetha indawo yangaphakathi ye-angle yefayili yefayili, qwa lasela ukuba wenze indawo encinci yefayile engenamazinyo isondele kwicala langaphakathi le-angle-angle ukuphepha umonakalo kwi-right-angle surface.

Ubunzima bamazinyo anqunywe kufuneka bukhethwe ngokobukhulu besibonelelo, ukuchaneka kwe-machining kunye nempahla yezinto eziphathekayo ze-workpiece. Iifayile ze-coarse-tooth zifanelekile kwi-workpieces kunye nezibonelelo ezinkulu ze-machining, ukuchaneka kwe-dimensional low, ukunyamezela okukhulu kwejometri, amaxabiso amakhulu obunzima bomhlaba, kunye nezinto ezithambileyo; ngokuchaseneyo, iifayile ze-fine-tooth kufuneka zisetyenziswe. Xa usebenzisa, kufuneka kukhethwe ngokuhambelana nesibonelelo somatshini, ukuchaneka kobukhulu kunye nobunzima bomhlaba obufunwa yi-workpiece.

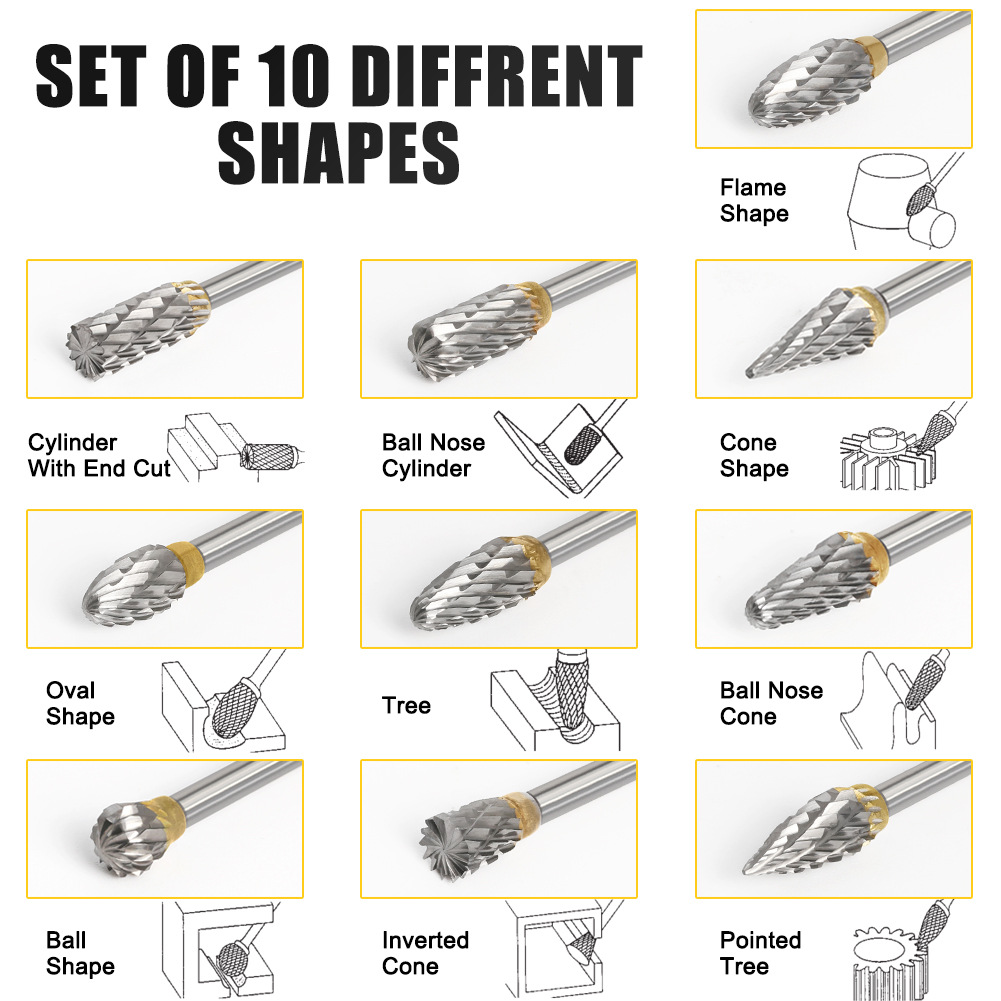

Ubungakanani kunye nokucaciswa kwentloko yensimbi ye-tungsten kufuneka ikhethwe ngokuhambelana nobukhulu kunye nesibonelelo somatshini womsebenzi oza kucutshungulwa. Xa ubukhulu bokucubungula bukhulu kwaye isibonelelo sikhulu, ifayile enobungakanani obukhulu kufuneka ikhethwe. Ubume bezinyo lwefayile ye-tungsten yensimbi yokugaya kufuneka ikhethwe ngokobume bezinto eziza kufakwa. Xa ufaka izinto ezithambileyo ezifana ne-aluminium, ubhedu, kunye nentsimbi ephantsi yekhabhoni, kungcono ukusebenzisa ifayile yezinyo elinye.

Izinto eziluncedo zeCarbide Tip Rotary Burr:

1. Iyakwazi ukucubungula izinyithi ezifana nentsimbi, isinyithi, i-carbon steel, i-alloy steel, isinyithi esingenasici, ithusi kunye ne-aluminium, kunye ne-non-metals njenge-marble, i-jade kunye nethambo.

2. Inokuthi ngokusisiseko ithathe indawo yevili elincinane lokusila ngesiphatho, akukho lungcoliseko lothuli kunye nokusebenza kakuhle kwemveliso. Ukusebenza kakuhle kokusebenza kumaxesha amaninzi aphezulu kuneefayile zezandla, kwaye phantse amaxesha alishumi aphezulu kunalawo amavili amancinci okusila anezibambo.

3. Umgangatho wokuqhuba kakuhle kunye nokugqiba okuphezulu. Iyakwazi ukwenza imingxuma yokungunda yeemilo ezahlukahlukeneyo ezichaneke kakhulu, kwaye ukuqina kwayo kuphakame ngokuphindwe kalishumi kunoko kwezixhobo zentsimbi ezinesantya esiphezulu yaye ngaphezu kwamaxesha angama-200 aphezulu kunokwamavili amancinane okusila. Kulula ukuyiqonda, kulula ukuyisebenzisa, ikhuselekile kwaye inokuthenjwa.

Ukwandisa ubomi benkonzo ye-tungsten yentsimbi yokusila intloko, le migaqo ilandelayo kufuneka igcinwe:

1. Akuvumelekanga ukusebenzisa iifayile ezintsha ze-carbide rotary ukutyumza iintsimbi ezinzima;

2. Akuvumelekanga ukusebenzisa i-tungsten steel head grinding head to file material hard, forgings and castings with skin hard or isanti sticky sand. Kufuneka zicolwe kwi-grinder ngaphambi kokuba zifakwe kwifayile enesiqingatha;

3. Sebenzisa elinye icala le-tungsten carbide rotary burrs kuqala, uze usebenzise elinye icala emva kokuba umphezulu uba buthuntu. Ngalo lonke ixesha sebenzisa ibrashi yocingo ukususa inkunkuma kwindawo esikiweyo xa usikwa, kwaye ukusikwa akufuneki kugqithe okanye kupakishwe nezinye izixhobo.

Ukuba ufuna ukuthenga i-carbide rotary burrs, nceda undwendwele iwebhusayithi yethu:https://www.mskcnctools.com/3mm-shank-carbide-tip-rotary-burr-cut-carving-bit-product/

Okanye uqhagamshelane noMolly WhatsApp: +8613602071763 ukufumana uluhlu lwamaxabiso.

Ixesha lokuposa: Oct-19-2022