Kwihlabathi elikhawulezayo lemveliso ye-elektroniki, apho ukuchaneka kwe-micron-level ichaza impumelelo, ukuqaliswa kwe-Next-Gen PCB Board Drill Bits kuphawula ukutsiba kwe-quantum kwibhodi yesekethe. Yenzelwe ukugrumba, ukukrola, kunye ne-micromachining kwiibhodi zesekethe eziprintiweyo (PCBs) kunye nezinye ii-ultra-thin substrates, ezi Tungsten Steel.Mini Drill PCBIzixhobo zidibanisa izixhobo ze-aerospace-grade kunye neteknoloji yokuzinza kwe-seismic ukuchaza kwakhona ukusebenza kakuhle kunye nokuphila ixesha elide kwimveliso ephezulu.

UbuNjineli obuGqwesileyo: Kutheni i-Tungsten Steel ibalulekile

Embindini wale mibhobho ye-drill ilele i-high-purity tungsten carbide (WC), imathiriyeli ekhethelwe ukudityaniswa kobunzima obungalinganiyo (HRA 92), ukuxhathisa ukunxiba, kunye nokuthembeka kwesakhiwo. Ngokungafaniyo ne-HSS eqhelekileyo (i-High-Speed Steel) yoqheliso, olu qulunqo lwentsimbi ye-tungsten luhambisa:

3X Ubomi obude: Ukumelana nemijikelo eyi-15,000+ yokomba kwiibhodi ze-fiberglass ze-FR-4 ngaphandle kokuthotywa komphetho.

Ulwakhiwo lweMicro-Grain: I-Sub-0.5µm iinkozo ze-carbide ziqinisekisa imiphetho yokusika i-razor-ebukhali, ukufikelela kwidayamitha yomngxuma ibencinci njenge-0.1mm kunye ne-±0.005mm yokunyamezela.

Uyilo lwe-Anti-Fracture: I-geometry ye-shank eyomeleziweyo ikhusela ukuphuka ngexesha le-RPM ephezulu (30,000-60,000) yokusebenza, nakwizinto eziphathekayo ze-PCB ezizaliswe yi-ceramic.

Uvavanyo lomntu wesithathu yi-Precision Machining Institute of Technology iqinisekisa ukuba ezi bits zigcina i-Ra 0.8µm yokugqiba umphezulu emva kwemingxuma ye-10,000 - into ebaluleke kakhulu kwi-high-frequency signal integrity in 5G kunye nezixhobo ze-IoT.

Uzinzo lweSeismic: Ukusika Ngaphandle Kokulalanisa

Ukugrumba kwePCB kufuna uzinzo olupheleleyo ukuthintela "ukuhamba" okanye ukungahambi kakuhle komngxuma. Uyilo loMda weSeismic Blade Edge ujongana noku:

Ijiyometri yeFlute ye-Asymmetric: Ilinganisa ukufuduswa kwetshiphu kunye ne-vibration damping, ukunciphisa amandla asecaleni ngama-40%.

I-Nano-Coated Helix Angle: I-30 ° i-helix ene-TiAlN yokugubungela inciphisa ukwakhiwa kobushushu (<70 ° C) ngexesha lokusebenza okuqhubekayo.

I-Anti-Resonance Grooves: I-Laser-etched micro-channels iphazamisa i-harmonic frequencies, iqinisekisa ukuchaneka kwendawo ngaphakathi kwe-5µm kwi-10-layer PCBs.

Kuvavanyo loxinzelelo lokomba imingxuma eyi-0.3mm nge-2mm yeebhodi ze-aluminium-clad, ezi bits zibonise ukutenxa kwi-zero kwimijikelo engama-500 elandelelanayo - into engenakuthelekiswa nabakhuphisana nabo.

Izicelo kuwo wonke amaShishini

I-Electronics yabathengi

Kubenzi bebhodi ye-smartphone:

I-0.2mm Micro-Vias: Iphumelele i-99.9% imilinganiselo yesivuno kwiibhodi ze-HDI ze-12-layer.

I-20% Amaxabiso okutya okuKhawuleza: Yenziwe ngokunciphisa ukukhuhlana kunye ne-chip clogging.

I-Electronics yeemoto

Kwimveliso yemodyuli yamandla e-EV:

Ngokuthembeka kwe-Hole: Igcinwe i-100% yokuqhubekeka kombane kwi-1.6mm-thick-thermal-conductive substrates.

UkuSebenza kwaMahala okuPholisa: Ukukwazi ukugrumba okomileyo kuthintela ungcoliseko kwiinkqubo zolawulo lwebhetri etywiniweyo.

I-Aerospace kunye noKhuseleko

Ukugrumba imingxunya eyi-0.15mm kwiisekethe ze-polyimide flex:

Zero Delamination: Nakwi-200°C kwindawo zokufuma okuphezulu.

I-EMI Shield Patterning: Umzobo ochanekileyo wegraphene-based RF shielding layering.

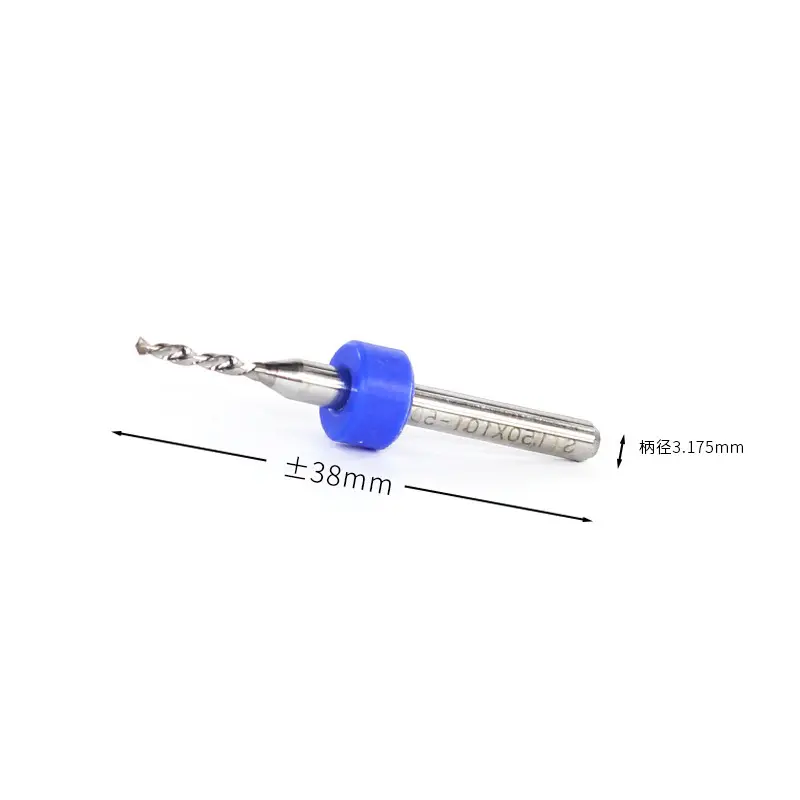

IiNgcaciso zobuGcisa

Uluhlu lweDiameter: 0.1mm–3.175mm (0.004"–1/8")

Uhlobo lwe-Shank: Umgangatho we-3.175mm (1/8") okanye ukuhambelana kwe-collet yesiko le-ER

Iinketho zokugquma: iTiN (igolide), iTiCN (ebhlowu), okanye iDiamond-NjengeCarbon (DLC)

Ubukhulu be-RPM: 80,000 (ixhomekeke kububanzi)

Ukuhambelana: oomatshini bokomba be-CNC, oomatshini bokuchwetheza bePCB abazenzekelayo, izixhobo ezijikelezayo eziphathwa ngesandla

Ukuchazwa ngokutsha kweendleko

Uhlalutyo lweendleko-inzuzo eyenziwe ngumqambi ophambili we-PCB waseTaiwan utyhile:

$18,500 Annual Savings: Yehlisiwe drill bit replacements (ukusuka 12 ukuba 4 iiseti / ngonyaka).

I-15% yokuNcitshiswa kwamandla: Iimfuno eziphantsi ze-spindle torque.

I-Zero Rework: Kupheliswe i-220k yeedola ngonyaka kwiibhodi ezilahliweyo ukusuka kwi-drill wander.

Uzinzo olwakhelwe ngaphakathi

Ukupakishwa okuRecyclable: I-100% yeetreyi ze-foam ezinokonakala.

I-RoHS & FIKELELA kuThotyelo: Isimahla kwilothe, i-cadmium, kunye nezinye izinto eziyingozi.

Ubomi besixhobo esandisiweyo: I-60% yokusetyenziswa kwe-tungsten ephantsi vs.

Iingqinisiso zabasebenzisi

"Ukutshintshela kwezi ntsimbi zentsimbi ye-tungsten kwakutshintshile," utshilo u-Hiroshi Tanaka, uMphathi weMveliso kumenzi wenzwa esekwe eKyoto. "Sigrumba imingxuma engama-20,000 kwishifti nganye ngaphandle kotshintsho lwesixhobo - into engenakucingelwa ngoqheliso lwethu oludala lwe-HSS. Uyilo lwenyikima lulodwa lunqumle ukugatywa kwethu kwemingxuma ngama-95%.

Kutheni le nto ukhethe ezi Bits zeBhodi yePCB?

Ukuchaneka okungaqhawukiyo: Ukuchaneka okufana ne-laser kwiibhodi ze-high-density interconnect (HDI).

Isantya ngaphandle kwedini: Gcoba imingxuma eyi-0.3mm kwimingxuma engama-400 / ngomzuzu ngaphandle kokunciphisa umgangatho womgangatho.

I-Universal Compatibility: Isebenza kunye ne-FR-4, i-Rogers, i-aluminium, kunye ne-laminates eqiniswe ngeglasi.

Uyilo-bubungqina bexesha elizayo: Ilungele izixhobo zePCB ezizayo ezifana ne-halogen-free kunye ne-ultra-low-low- loss dielectrics.

Ukuqukumbela

Kwishishini apho yonke i-micron iyalela ingeniso kunye nokusebenza, ezi Tungsten SteelPCB Board Drill Bitszingaphezulu kwezixhobo – ziluncedo lweqhinga. Ngokudibanisa isayensi yezinto eziphathekayo kunye nobunjineli obuzinzo, baxhobisa abavelisi ukuba batyhale imida ye-miniaturization ngelixa beqhekeza.

Ixesha lokuposa: Mar-21-2025