Icandelo loku-1

I-workpiece overcut:

isizathu:

I-1) Ukubetha i-cutter, isixhobo asinamandla ngokwaneleyo kwaye side kakhulu okanye sincinci kakhulu, sibangela ukuba isixhobo siqhume.

2) Ukusebenza okungafanelekanga ngumqhubi.

3) Isibonelelo sokusika esingalinganiyo (umzekelo: shiya i-0.5 kwicala lendawo egobileyo kunye ne-0.15 ngasezantsi) 4) Iiparamitha zokusika ezingafanelekanga (umzekelo: ukunyamezela kukhulu kakhulu, ukusetwa kwe-SF kukhawuleza kakhulu, njl.)

ukuphucula:

I-1) Sebenzisa umgaqo wokusika: unokuba mkhulu kodwa ungabi ncinane, unokuba mfutshane kodwa ungabi kude.

2) Yongeza inkqubo yokucoca ikona, kwaye uzame ukugcina umda njengoko kunokwenzeka (umda kwicala kunye nezantsi kufuneka uhambelane).

3) Ukulungelelanisa ngokufanelekileyo iiparitha zokusika kwaye ujikeleze iikona ezinemida emikhulu.

I-4) Ukusebenzisa umsebenzi we-SF wesixhobo somatshini, umqhubi unokulungelelanisa isantya ukuze afezekise umphumo ongcono wokusika wesixhobo somatshini.

Icandelo lesi-2

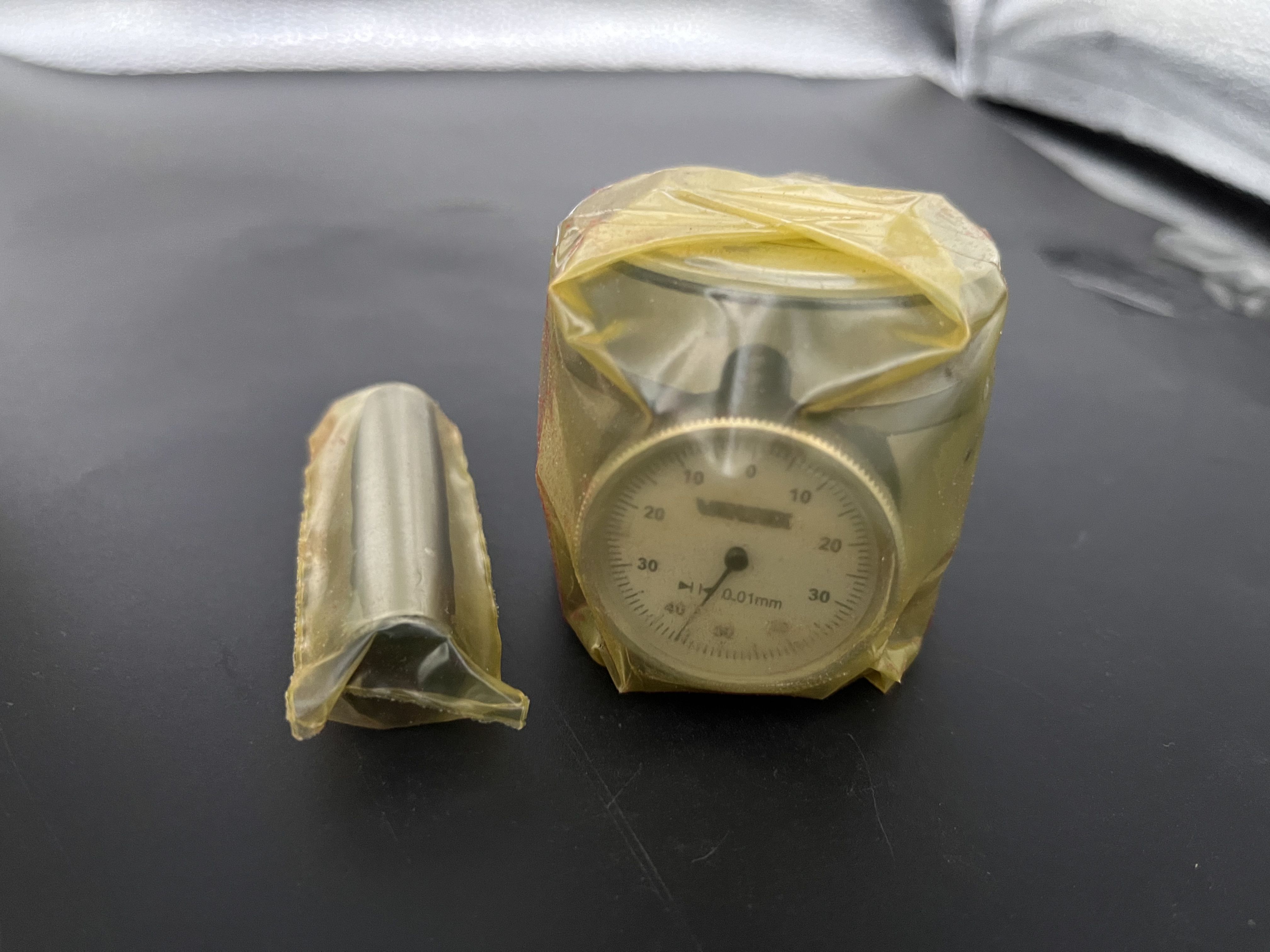

Ingxaki yokumisela isixhobo

isizathu:

1) Umsebenzisi akachanekanga xa esebenza ngesandla.

2) Isixhobo asibambeki kakuhle.

3) I-blade kwi-flying cutter ayilunganga (i-flying cutter ngokwayo ineempazamo ezithile).

4) Kukho impazamo phakathi kwe-R cutter, i-flat cutter kunye ne-flying cutter.

ukuphucula:

I-1) Imisebenzi yezandla kufuneka ihlolwe ngokucophelela ngokuphindaphindiweyo, kwaye isixhobo kufuneka sibekwe kwindawo efanayo kangangoko kunokwenzeka.

2) Xa ufaka isixhobo, sivuthele ngompu womoya okanye usule nge-rag.

3) Xa i-blade kwi-flying cutter idinga ukulinganiswa kumphathi wesixhobo kwaye umgangatho ophantsi uphothiwe, i-blade ingasetyenziswa.

I-4) Inkqubo yokumisela isixhobo esahlukileyo inokuphepha iimpazamo phakathi kwe-R cutter, i-flat cutter kunye ne-flying cutter.

Icandelo lesi-3

Collider-Ucwangciso

isizathu:

1) Ukuphakama kokhuseleko akwanelanga okanye kungacwangciswanga (i-cutter okanye i-chuck ibetha i-workpiece ngexesha lokutya ngokukhawuleza kwe-G00).

2) Isixhobo esikuluhlu lweprogram kunye nesona sixhobo seprogram sibhalwe ngokungalunganga.

3) Ubude besixhobo (ubude be-blade) kunye nobunzulu bokusebenza ngokuchanekileyo kwiphepha leprogram kubhalwe ngokungalunganga.

4) Ubunzulu be-Z-axis fetch kunye neyona nto yokulanda i-Z-axis ibhalwe ngokungachanekanga kwiphepha leprogram.

5) Ulungelelwaniso lusekwe ngokungalunganga ngexesha lokucwangcisa.

ukuphucula:

1) Ukulinganisa ngokuchanekileyo ubude bomsebenzi kwaye uqinisekise ukuba ukuphakama okukhuselekileyo kungaphezulu kwendawo yokusebenza.

2) Izixhobo ezikuluhlu lwenkqubo kufuneka zihambelane nezona zixhobo zeprogram (zama ukusebenzisa uluhlu lwenkqubo oluzenzekelayo okanye usebenzise imifanekiso ukuvelisa uluhlu lweprogram).

3) Ukulinganisa ubunzulu bokwenene bokucubungula kwi-workpiece, kwaye ubhale ngokucacileyo ubude kunye nobude be-blade yesixhobo kwiphepha leprogram (ngokubanzi ubude be-clamp yesixhobo buyi-2-3MM ephezulu kune-workpiece, kunye nobude be-blade yi-0.5-1.0MM).

4) Thatha eyona nombolo ye-Z-axis kwi-workpiece kwaye uyibhale ngokucacileyo kwiphepha leprogram. (Lo msebenzi ubhalwa ngokubanzi ngesandla kwaye kufuneka ujongwe ngokuphindaphindiweyo).

Icandelo 4

Collider-Operator

isizathu:

1) Ubunzulu Z impazamo yokucwangcisa isixhobo somgca ohamba phambili

2) Inani lamanqaku libethelwe kwaye umsebenzi awulunganga (njengoku: ukuthabatha unilateral ngaphandle kweradius feed, njl.).

3) Sebenzisa isixhobo esingalunganga (umzekelo: sebenzisa isixhobo se-D4 kunye nesixhobo se-D10 sokucubungula).

4) Inkqubo ayihambanga kakuhle (umzekelo: i-A7.NC iye kwi-A9.NC).

5) I-handwheel ijikeleza kwicala elingalunganga ngexesha lokusebenza ngesandla.

6) Cinezela indlela engalunganga ngexesha lokuhamba ngokukhawuleza (umzekelo: -X cinezela +X).

ukuphucula:

1) Xa usenza isixhobo esinzulu se-Z-axis, kufuneka ubeke ingqalelo apho isixhobo sisetwa khona. (Umphezulu osezantsi, umphezulu, umphezulu wokuhlalutya, njl.).

2) Jonga inani lokubetha kunye nokusebenza ngokuphindaphindiweyo emva kokugqitywa.

3) Xa ufaka isixhobo, jonga ngokuphindaphindiweyo ngephepha leprogram kunye neprogram ngaphambi kokuba uyifake.

4) Inkqubo kufuneka ilandelwe nganye nganye ngokulandelelana.

5) Xa usebenzisa umsebenzi wezandla, umqhubi ngokwakhe kufuneka aphucule ubuchule bakhe ekusebenziseni isixhobo somatshini.

6) Xa uhambisa ngesandla ngokukhawuleza, unokuphakamisa kuqala i-Z-axis kwindawo yokusebenza ngaphambi kokuba uhambe.

Icandelo 5

Ukuchaneka komphezulu

isizathu:

I-1) Iiparamitha zokusika azinangqiqo kwaye i-workpiece surface inzima.

2) Umgca wokusika wesixhobo awubukhali.

I-3) Isixhobo sokudibanisa isixhobo side kakhulu kwaye ukukhutshwa kwe-blade kude kakhulu.

4) Ukususwa kweChip, ukuvuthuza komoya, kunye nokugungxulwa kweoyile akulunganga.

5) Inkqubo yokondla isixhobo senkqubo (ungazama ukuqwalasela ukugaya).

6) I-workpiece ine-burrs.

ukuphucula:

I-1) Ukusika iiparamitha, ukunyamezela, izibonelelo, isantya kunye nezicwangciso zesondlo kufuneka zibe nengqiqo.

I-2) Isixhobo sifuna ukuba umqhubi ahlolisise kwaye athathe indawo yaso ngamaxesha athile.

I-3) Xa i-clamping isixhobo, umqhubi kufuneka agcine i-clamp mfutshane kangangoko kunokwenzeka, kwaye i-blade ayifanele ibe yinde kakhulu ukuphepha umoya.

4) Ukunciphisa ngeemela ezisicaba, iimela ze-R, kunye neemela zempumlo ezingqukuva, isantya kunye noseto lwesondlo kufuneka lube nengqiqo.

I-5) I-workpiece ine-burrs: Ihambelana ngokuthe ngqo kwisixhobo sethu somatshini, isixhobo, kunye nendlela yokondla izixhobo, ngoko ke kufuneka siqonde ukusebenza kwesixhobo somatshini kwaye senze imida ngee-burrs.

Icandelo 6

edge yokutshiphuza

1) Yondla ngokukhawuleza kakhulu--cotha ukuya kwisantya esifanelekileyo sokutya.

2) Isondlo sikhawuleza kakhulu ekuqaleni kokusika--cotha isantya sokutya ekuqaleni kokusika.

3) I-clamp ikhululekile (isixhobo) - i-clamp.

4) I-clamp ikhululekile (i-workpiece) - i-clamp.

5) Ukungonelanga kokuqina (isixhobo) - Sebenzisa esona sixhobo sifutshane sivumelekileyo, cinezela isiphatho nzulu, kwaye uzame ukusila.

I-6) Umgca wokusika wesixhobo ubukhali kakhulu - tshintsha i-angle e-fragile cut edge, i-primary edge.

I-7) Isixhobo somatshini kunye nomphathi wesixhobo asiqinile ngokwaneleyo - sebenzisa isixhobo somatshini kunye nomphathi wesixhobo esinobungqongqo obuhle.

Icandelo lesi-7

nxibela ukuyikrazula

1) Isantya somatshini sikhawuleza kakhulu-cotha kwaye wongeze i-coolant eyaneleyo.

I-2) Izinto ezilukhuni-zisebenzise izixhobo zokusika eziphambili kunye nezixhobo zesixhobo, kunye nokwandisa iindlela zonyango zonyango.

3) I-chip adhesion - tshintsha isantya sokutya, ubukhulu be-chip okanye usebenzise ioli yokupholisa okanye umpu womoya ukucoca iitshiphusi.

4) Isantya feed ayifanelekanga (ephantsi kakhulu) - ukwandisa isantya feed kwaye uzame phantsi milling.

5) I-angle yokusika ayifanelekanga--yitshintshe kwi-angle yokusika efanelekileyo.

I-6) I-angle yokunceda ephambili yesixhobo incinci kakhulu - yitshintshe kwi-angle enkulu yokunceda.

Icandelo 8

ipateni yokungcangcazela

I-1) Ukutya kunye nesantya sokusika ngokukhawuleza--lungisa ukutya kunye nesantya sokusika

2) Ukungonelanga kokuqina (isixhobo somatshini kunye nomphathi wesixhobo) -sebenzisa izixhobo zomatshini ezingcono kunye nabaphethe izixhobo okanye utshintshe iimeko zokusika

3) I-engile yokukhulula inkulu kakhulu-yitshintshe ibe yi-engile yokukhulula encinci kwaye usebenze umda (sebenzisa i-whetstone ukuze ulole i-edge kube kanye)

4) Bamba ngokukhululekileyo--bamba i-workpiece

5) Qwalasela isantya kunye nemali yokutya

Ubudlelwane phakathi kwezinto ezintathu zesantya, ukondla kunye nokusika ubunzulu yeyona nto ibalulekileyo ekunqumeni umphumo wokusika. Isondlo esingafanelekanga kunye nesantya sisoloko sikhokelela ekunciphiseni imveliso, umgangatho ombi womsebenzi, kunye nomonakalo omkhulu wesixhobo.

Ixesha lokuposa: Jan-03-2024