Ukuqhuba okungayekiyo ukuya kwiimoto ezikhaphukhaphu, ezomeleleyo, nezisebenzayo ngakumbi, ngakumbi ngokukhula okugqabhukileyo kweZiThuthi zoMbane (EVs), kubeka uxinzelelo olukhulu ekwenzeni iimoto. Iindlela zemveli zokwenza uqhagamshelo oluluqilima oluluqilima kwintsimbi ecekethekileyo - isiseko semizimba yemoto yanamhlanje, iifreyimu, kunye neendawo ezivaliweyo - zihlala zibandakanya iziqhoboshi ezongezelelweyo ezifana ne-weld nuts okanye rivet nuts. Ezi zazisa ubunzima, ubunzima, amanqaku angaphumeleli, kunye namaxesha okucotha komjikelo. Faka i-Thermal Friction Drilling (TFD) kunye nezixhobo zayo ezikhethekileyo-I-Carbide Flow Drill Bits kunye ne-Thermal Friction Drill Bit Sets - iteknoloji eguqula ngokukhawuleza imigca yemveliso yeemoto ngokwenza ngokuzenzekelayo ukudala okudibeneyo, okunamandla aphezulu ngokuthe ngqo ngaphakathi kwezinto ezincinci.

Umngeni wokuQinisa iMoto: Ubunzima, amandla, isantya

Iinjineli zeemoto zihlala zisilwa nomxakatho wokomelela ubunzima. Iintsimbi ezinqabileyo, eziphezulu kunye ne-aluminium alloys ziyimfuneko ekunciphiseni ubunzima bezithuthi kunye nokuphucula ukusebenza kakuhle kwamafutha okanye uluhlu lwe-EV. Nangona kunjalo, ukwenza imisonto enokuthenjwa ethwele umthwalo kula macandelo amancinci kuyingxaki:

Uthethathethwano olulinganiselweyo: Ukuchwetheza ngokwemveli kwiphepha elicekethekileyo kunika ukubandakanyeka okuncinci komsonto, okukhokelela kumandla aphantsi wokutsalwa kunye nokuba sesichengeni sokuhluba.

I-Complexity eyongeziweyo kunye nobunzima: I-Weld nuts, i-clinch nuts, okanye i-rivet nuts yongeza iinxalenye, ifuna imisebenzi yesibini (i-welding, i-pressing), ukwandisa ubunzima, kunye nokwazisa iindawo ezinokubakho zokubola okanye imiba yokulawula umgangatho.

IiBottlenecks zeNkqubo: Ukugaya okwahlukileyo, ukufakwa kwe-fastener / uncamathiselo, kunye nokucofa amanyathelo acotha imigca yokuvelisa umthamo ophezulu.

Ubushushu kunye nokuPhathwa: I-Welding nuts ivelisa ubushushu obubonakalayo, obunokuthi bube ne-warping panels ezibhityileyo okanye ezichaphazela iipropathi zemathiriyeli kwiNdawo eChatshazelwe bubushushu (HAZ).

Flow Drills: Isisombululo esizenzekelayo kumgca

I-Thermal Friction Drilling, edityaniswe kumaziko omatshini e-CNC, iiseli zerobhothi, okanye oomatshini abajikijelweyo abaninzi, inika impendulo enyanzelisayo:

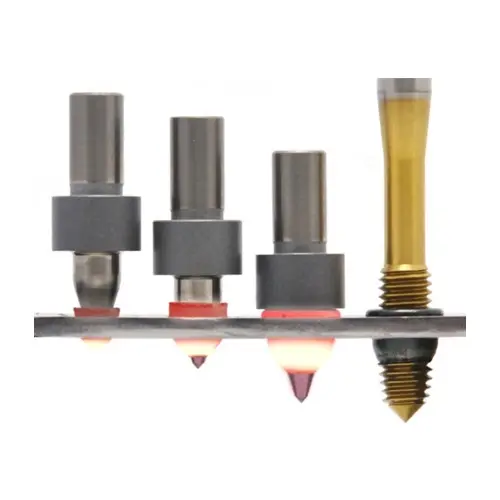

I-Single Operation Powerhouse: Owona mlingo we-TFD ulele ekudibaniseni ukomba, ukubunjwa kwamahlahla, kunye nokucofa kwintsebenzo enye engenamthungo, ezenzekelayo. I-Carbide Flow Drill Bit enye, ejikelezayo ngesantya esiphezulu (ngokuqhelekileyo i-3000-6000 RPM yentsimbi, ephezulu ye-aluminiyam) phantsi kwe-axial force ebalulekileyo, ivelisa ukushisa okukhulu kwe-friction. Oku kwenza isinyithi seplastiki senziwe ngeplastiki, sivumela ijometri ekhethekileyo yesuntswana ukuba ihambe kwaye ishenxise imathiriyeli, yenze i-bushing engenamthungo, edityanisiweyo malunga namaxesha ama-3 ubukhulu bephepha lokuqala.

Ukucofa kwangoku: Njengoko i-Flow Drill irhoxa, impompo eqhelekileyo (ehlala ikwisixhobo esinye kwisiphathi-sixhobo sotshintshiselwano ngokuzenzekelayo okanye i-spindle yesibini elungelelanisiweyo) ilandela ngokukhawuleza, ukusika imisonto echaneke kakhulu kule bushing entsha, enodonga olungqindilili. Oku kuphelisa ukuphatha phakathi kwemisebenzi kwaye kunciphisa kakhulu ixesha lokujikeleza.

Ukudityaniswa kweRobhothi: Iseti yeBit ye-Thermal Friction Drill ifanelekele ngokufanelekileyo iingalo zerobhothi. Ukukwazi kwabo ukwenza yonke inkqubo yokudala intambo ngendlela enye yesixhobo (ukuqhuba phantsi, ukwenza i-bushing, ukuhlehlisa, ukucofa phantsi, ukurhoxisa) kwenza kube lula ukucwangciswa kwerobhothi kunye nokwenziwa. Iirobhothi zinokusibeka ngokuchanekileyo isixhobo phezu kweekhontolo ezintsonkothileyo kwizakhiwo zomzimba-ezimhlophe (BIW) okanye ii-sub-assemblies.

Kutheni abavelisi beeMoto besenza iiDrills eziHambayo:

Ukonyuka ngamandla komsonto: Le yeyona nzuzo iphambili. Imisonto ibandakanya ihlathi elishinyeneyo (umzekelo, ukwenza i-9mm ubude ukusuka kwiphepha le-3mm), okukhokelela ekutsaleni ngaphandle kunye namandla okuqhawula ahlala edlula lawo e-weld nuts okanye i-rivet nuts. Oku kubalulekile kumacandelo abalulekileyo okhuseleko (iiankile zebhanti lesihlalo, ukuxhoma okuxhomayo) kunye neendawo ezingcangcazelayo.

Ukunciphisa Ubunzima obubalulekileyo: Ukuphelisa i-weld nut, i-rivet nut, okanye i-clinch nut ngokwayo isusa ubunzima. Okubaluleke ngakumbi, ihlala ivumela abaqulunqi ukuba basebenzise i-gauge ye-thinner material ngokubanzi ekubeni i-bushing ebunjiweyo ibonelela ngokuqiniswa kwendawo apho kufuneka khona amandla, ngaphandle kokongeza ubunzima kwenye indawo. Iigram ezigciniweyo ngoqhagamshelwano ziphindaphinda ngokukhawuleza kwisithuthi.

Ubuchule beNkqubo obungahambelaniyo kunye nesantya: Ukudibanisa imisebenzi emithathu ibe ngamaxesha omjikelo we-slash. Umjikelo we-thermal friction drilling kunye nomjikelo wokucofa unokugqitywa kwimizuzwana emi-2-6, ngokukhawuleza kakhulu kunokwemba okulandelelanayo, ukubekwa kwamantongomane / ukuwelda, kunye nokucofa. Oku kwandisa umthamo kwimigca yomthamo ophezulu.

Umgangatho owomeleziweyo kunye nokungaguquguquki: I-TFD ezenzekelayo ihambisa umngxuma ukuya kumngxunya ngendlela engaqhelekanga. Inkqubo iphinda iphindwe phantsi kwe-CNC elawulwayo okanye i-robotic parameters, ukunciphisa impazamo yomntu eqhelekileyo ekubekeni i-nut manual okanye i-welding. I-bushing ebunjiweyo idala umngxuma ogudileyo, osoloko uvalekile, uphucula ukumelana nokubola kunye nokuncamathela kwepeyinti.

UkuNcitshiswa kweNkqubo yokuNxina kunye neNdleko: Ukuphelisa i-nut feeders eyahlukileyo, izikhululo ze-welding, abalawuli be-weld, kunye nokujonga umgangatho ohambelanayo kunciphisa iindleko zezixhobo zenkunzi, iimfuno zendawo yomgangatho, ubunzima bokulondolozwa, kunye nezinto ezisetyenziswayo (akukho cingo lwe-welding / igesi, akukho nuts).

UkuPhuculwa kweMfezeko eDityanisiweyo: I-integrated bushing yenza i-metallurgical eqhubekayo inxalenye yesiseko semathiriyeli. Akukho mngcipheko wokukhulula i-nut, ukujikeleza, okanye ukuwa njengezibophelelo zoomatshini, kwaye akukho nkxalabo ye-HAZ inokuthelekiswa ne-welding.

I-Material Versatility: I-Carbide Flow Drill Bits iphatha ngokufanelekileyo izinto ezahlukeneyo kwiimoto zanamhlanje: insimbi ethambileyo, i-High-Strength Low-Alloy (HSLA) insimbi, i-Advanced High-Strength Steel (AHSS), i-aluminium alloys (5xxx, 6xxx), kunye nezinye izinto ezingenasici. Iingubo zesixhobo (ezifana ne-AlCrN ye-aluminium, i-TiAlN yentsimbi) yenza ngcono ukusebenza kunye nobomi.

Ukwenziwa koMfundiso oPhambili kwiZithuthi zokuQhuba:

I-EV iBattery Enclosures & Tray: Mhlawumbi umqhubi omnye omkhulu. Ezi zakhiwo zinkulu, ezinodonga olucekethekileyo (ngokuqhelekileyo i-aluminiyam) zifuna amandla amaninzi aphezulu, iindawo ezivuzayo ezivuzayo zokuxhoma, izigqubuthelo, iipleyiti zokupholisa, kunye nezixhobo zombane. I-TFD inika amandla afunekayo ngaphandle kokongeza ubunzima okanye ubunzima. I-bushing evaliweyo inceda ukuthintela ukungena kwesipholisi.

I-Chassis kunye ne-Subframes: Iibrakethi, ii-crossmembers, kunye neendawo zokuxhoma zokuxhoma zixhamla kumandla e-TFD kunye nokumelana nokungcangcazela kwiintsimbi ezincinci, eziphezulu.

Iifreyimu zeZitulo kunye neeNdlela zokuSebenza: Amacandelo okhuseleko abalulekileyo afuna ukomelela okuphezulu kakhulu kokutsalwa kwee-ankile zebhanti kunye neendawo ezomeleleyo zokuxhoma. I-TFD isusa izibophelelo ezinkulu kunye nokuphazamiseka kwe-welding.

I-Body-in-White (BIW): Izibiyeli ezahlukeneyo, iziqinisekiso, kunye neendawo zokunyusela zangaphakathi ngaphakathi kwesakhiwo sesithuthi apho amandongomane adityanisiweyo anzima kwaye ukuwelda kungafuneki.

I-Exhaust Systems: Ukuxhoma ii-hangers kunye neziqhotyoshelo zokukhusela ubushushu kwintsimbi encinci engenasici okanye i-aluminized steel inzuzo kumngxuma otywiniweyo onganyangekiyo kunye nokumelana nokungcangcazela.

IiYunithi ze-HVAC kunye nokuThuthwa: Iindawo zokunyuka kunye neepaneli zokufikelela kwinkonzo ezifuna imisonto eyomeleleyo kwiindawo ezivaliweyo zentsimbi.

Imfuneko yeCarbide kwi-Automotive TFD:

Imveliso yeemoto ibaleka inde, ifuna ukuthembeka kwesixhobo esipheleleyo kunye nobomi obude. I-Carbide Flow Drill Bits ayinakuxoxisana. Bamelana namaqondo obushushu obunzima obugqithisileyo (amaxesha amaninzi adlula i-800 ° C/1472 ° F kwincam), isantya esiphezulu sokujikeleza, kunye nemikhosi ebalulekileyo ye-axial idibane namawaka amaxesha ngokutshintsha. I-substrates ye-micro-grain carbide ephezulu kunye neengubo ezikhethekileyo (i-TiAlN, i-AlTiN, i-AlCrN) ilungiselelwe izinto ezithile zeemoto, ukwandisa ubomi besixhobo kunye nokugcina ukubunjwa kwe-bushing okuhambelanayo kunye nomgangatho womngxuma obaluleke kakhulu kwiinkqubo ezizenzekelayo. A egcinwe kakuhleIseti yeBit ye-Thermal Friction Drillinokuqhuba amawaka emingxuma phambi kokuba ifune ukutshintshwa, inikezela ngeendleko ezibalaseleyo ngomngxuma ngamnye.

Umanyaniso kunye neKamva:

Udibaniso oluyimpumelelo lubandakanya ulawulo oluchanekileyo lwe-RPM, amazinga esondlo, amandla e-axial, kunye nokupholisa (okuhlala kuncinci ukugqabhuka komoya endaweni yesikhukula esipholileyo ukunqanda ukucima ukwenza i-bushing). Iisistim zokubek'esweni zilandelela ukunxitywa kwesixhobo kunye nenkqubo yeeparamitha ukulungiselela ukugcinwa kwangaphambili. Njengoko uyilo lweemoto lutyhalela phambili kwizakhiwo zezinto ezininzi (umzekelo, imizimba ye-aluminiyam kwiifreyimu zentsimbi) kunye nokukhanya okukhulu ngakumbi, imfuno yetekhnoloji ye-Flow Drill iya kuqina kuphela. Ikhono layo lokudala i-localized, i-ultra-strong threads kwizinto ezincinci, ezihlukeneyo, ngokuthe ngqo ngaphakathi kokuhamba kwemveliso ezenzekelayo, izikhundla ze-Thermal Friction Drilling kungekhona nje njengenye indlela, kodwa njengomgangatho wexesha elizayo we-automotive fasting. Luguquguquko oluthe cwaka lwakha iimoto ezomeleleyo, ezikhaphukhaphu enye into edibeneyo ngexesha.

Ixesha lokuposa: Aug-21-2025