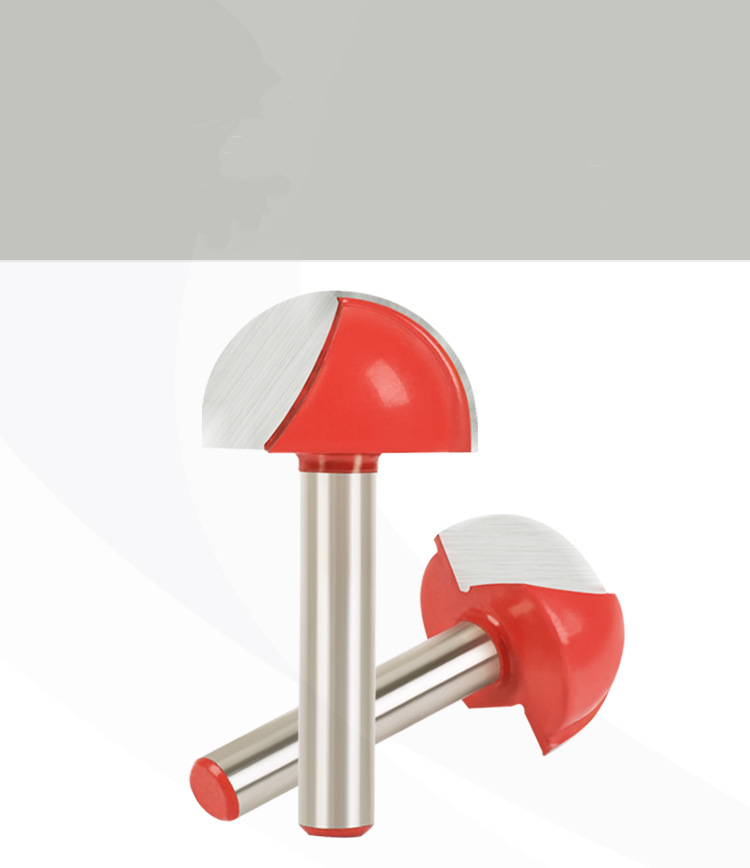

Milling Cutter Core Box Bit Round Round Ezantsi Round Intloko Umsiki womthi

UMBONO

Inkqubo ye-Welding High Frequency

I-interface igcwele umoya, iqinile kwaye akukho lula ukuyiqhawula

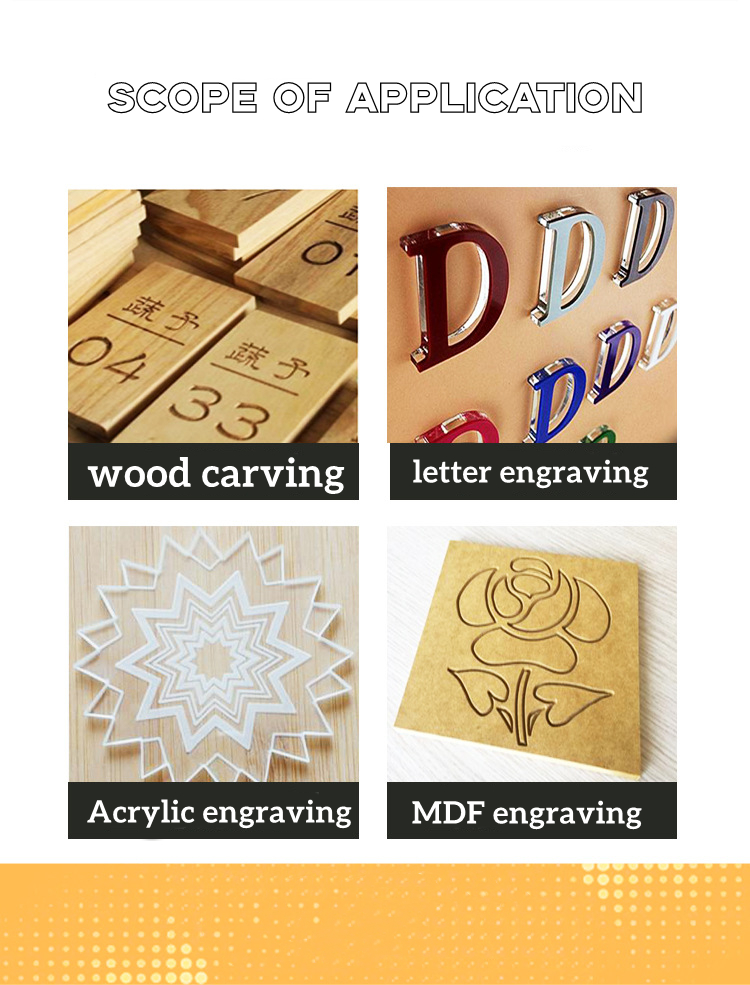

Ifanelekile ukukrola umthi

umkrolo weleta

Umkrolo weAkriliki

Ukukrolwa kweMDF

Ukwenziwa kwentsimbi yeTungsten, ubomi benkonzo ende, ukuxhasa ngokwezifiso

Akukho burrs, ukukhutshwa kakuhle kwetshiphu, udini lwemela ebukhali, ukuxhathisa ukunxiba kunye nokuqina

Uzinzo lwesakhiwo inkqubo evuthiweyo / intle kwaye ihlala ixesha elide

Umgangatho owenziwe ngokwezifiso uthembekile

Ubomi obude, ukuqina okuphezulu / ukusebenza kakuhle kweendleko

Inkonzo egqibeleleyo, inkonzo esondeleyo

Material Tungsten steel

Ukusika kunye nokukrola iinkuni, i-MDF, njl

Ubungakanani besicelo: ishishini leemoto, i-aerospace, ishishini lokungunda, ishishini le-IT

Inamachaphaza ngokupheleleyo

1.Ukwenza ngokwezifiso / ngaphezulu kweshelufu / umgangatho othembekileyo

2.Izinto ezikhethwayo zaseJamani tungsten steel toughness / imela ezine ezibukhali

3.Igudile ngaphandle kweebhula

Umphezulu ugudileyo kwaye uqhakazile, ubuninzi beechips bukhulu, kwaye umgca ukhawuleza

4. Ukumelana nokunxiba kunye nokuxhathisa okuphezulu kwe-corrosion

Akukho mhlwa kunye nokuxhathisa kwi-oxidation kwiindawo ezifumileyo

Indlela yokusebenzisa isixhobo somatshini wokukrola umthi:

1. I-Multi-stripe milling cutters iyacetyiswa ukuba i-rough machining ye-particleboard, njl.

2. Imela yokukrola idayimani iyacetyiswa ukuba ikrolwe kwisibuko se-acrylic.

3. Isiphumo sokusetyenziswa kwe-cutter ephantsi, indawo ephezulu yemveliso esetyenzisiweyo ayinayo i-burrs, kwaye akukho rocker ngexesha lokucubungula.

4. Kwibhodi ye-multi-layer kunye ne-splint processing, kucetyiswa ukuba usebenzise i-double-edged straight groove milling cutter.

5. Kwibhodi yoxinaniso oluphezulu kunye neenkuni eziqinileyo, kucetyiswa ukuba usebenzise i-ribbed cutter.

6. Ukusika okuphezulu kunye nezantsi kwe-burr-free, kucetyiswa ukuba usebenzise i-single-edge, i-double-edge top and bottom milling cutter.

7. Kuba isikhokho, MDF, virgin wood, PVC, acrylic enkulu-scale deep relief processing, kuyacetyiswa ukuba usebenzise enye-edged helical ball end milling cutter.

8. Ukuchaneka ngokuchanekileyo ukucutshungulwa koncedo oluncinci, kucetyiswa ukuba usebenzise i-cutter-bottomed cutter.

9. Ukusika i-aluminium plate, kucetyiswa ukuba usebenzise i-cutter ekhethekileyo ye-aluminium yokugaya i-single-edged. Akukho ukunamathela kwimela ngexesha lokucubungula, isantya esiphezulu kunye nokusebenza okuphezulu.

10. Ukusika i-MDF, kucetyiswa ukuba usebenzise i-helical milling cutter ephindwe kabini kunye nokususwa kwe-chip enkulu. Inemibhobho emibini yokususwa kwe-chip kunye ne-design-edged-eded, engenawo umsebenzi omhle wokususa i-chip, kodwa ifezekisa ibhalansi yesixhobo esihle. Xa kucutshungulwa iibhodi zoxinaniso oluphakathi kunye noluphezulu, luneempawu zokungabi namnyama, akukho msi womsi, kunye nobomi obude benkonzo.

11. Ukusika i-acrylic, kucetyiswa ukuba kusetyenziswe i-cutter ye-spiral milling cutter, ebonakaliswe ngokucofa umsi kunye nokungenavumba, isantya esikhawulezayo, ukusebenza kakuhle okuphezulu, akukho chips ezinamathele, kunye nokusingqongileyo ngokwenene. Inkqubo yayo ekhethekileyo yokuvelisa iqinisekisa ukuba i-acrylic ayiyi kuqhuma. , Ipateni yemela entle kakhulu (nangona ngaphandle kwepateni yemela), umphezulu ugudile kwaye ugudile. Umphezulu owenziwe ngoomatshini ufuna ukufezekisa i-frosted effect, kwaye kuyacetyiswa ukuba usebenzise i-double-edged three-edged three-edged spiral cutter.