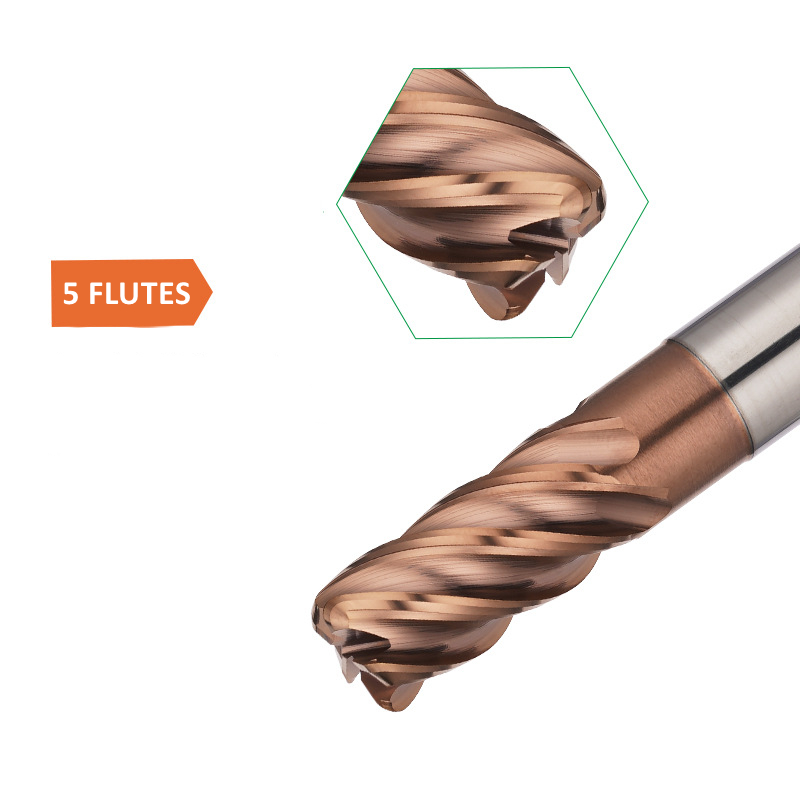

I-Corn Radius Mill ye-Nickel-Based High-Temp Alloys

INGCACISO YEMVELISO

I-Titanium yinto eyaziwayo enzima kakhulu kumatshini, ngakumbi kwiindlela zesixhobo ezinobundlongondlongo, ezifana nezo zinxulunyaniswa ne-High Efficiency Milling (HEM). Lo mgawuli wekona weradius milling usetyenziswa ngokukodwa ukusetyenzwa kwemathiriyeli kushishino lwenqwelomoya. Yamkela isitokhwe sebar yentsimbi ye-tungsten engeniswe ngaphandle kwaye inobomi obude benkonzo.

INGCEBISO YOKUSETYENZISWA KWIINDAWO YOKUSEBENZA

I-Titanium alloy TC18-21, i-ferrite, i-alloy ye-nickel ephezulu ngaphezu kwe-35%, i-high-temperature stainless steel, i-nickel-chromium-cobalt kunye nezinye i-alloys ze-titanium ezinzima, i-high-temperature alloy alloys.

Uyilo lwe-5-flute luyi-30% -40% ngokukhawuleza kune-3-flute/4-flute yokusila

Uyilo lweSeismic/Ultra High Metal Removal Rate/Uxinzelelo oluphantsi lwangaphakathi

| Flute Diameter | D6-D12 | Ubude beFlute | 8-24mm |

| Uhlobo lweFlute | Helical | Izinto eziphathekayo | I-tungsten yomgangatho ophezulu |

| Ukwaleka | Ewe | Uphawu | MSK |

| Uluhlu lokuqhubekekisa | Izinto ezinzima-ukusika izinto ezifana ne-titanium alloys, superalloys, ferrites, imizimba ye-nickel, i-high-temperature stainless steels, kunye ne-nickel-chromium-cobalt | ||

| Oomatshini abaSebenzayo | Oomatshini bokugaya, amaziko omatshini eCNC, iigongs zekhompyuter, oomatshini bokukrola | ||

UMBONO

1.Ekhethekileyo kwi-Titanium / i-superalloy enzima-ukusika izinto

Ixhotyiswe nge-lubricating ephezulu kunye ne-low friction coefficient coefficient coefficient yokunciphisa uxinzelelo lwangaphakathi lwezinto ezicutshungulwayo.

2.Geometry Flute

Uyilo olugqwesileyo lwe-5-blade ye-U-groove yejometri lunokwandisa indawo yoqhagamshelwano kunye nezinto eziza kucutshungulwa, ngelixa ukwandisa ukuqina kwesixhobo kunye nokuqinisekisa uburhabaxa obugqwesileyo bomhlaba.

3.Ibar yentsimbi ye-tungsten evela ngaphandle

Ukuchaneka kokunyamezela kwe-Shank ye-H5, eyenzelwe ngokukodwa iinkqubo ezichanekileyo ze-shank clamping.

4.Uyilo lweChamfer

Yenza kube lula ukuyibamba.

5.Uyilo lweSeismic

Isantya esiphezulu sokususa isinyithi, uxinzelelo lwangaphakathi olusezantsi, i-30% -40% ngokukhawuleza kune-3-blade / 4-blade yokusika abasiki

Isicelo:

I-aerospace, umkhosi, iinxalenye zoomatshini, iimoto, unxibelelwano olukhethekileyo lwe-elektroniki kunye namanye amacandelo

Inqaku lomthengi:

1. Ngaphambi kokusebenzisa isixhobo, nceda ulinganise ukuphambuka kwesixhobo. Xa ukuchaneka kwesixhobo sokuphambuka kudlula i-0.01mm, nceda ulungise ngaphambi kokusika.

2. Ubude obufutshane besixhobo esiphuma kwi-chuck, kungcono. Ukuba isixhobo sihlala ixesha elide, isantya, izinga lokutya kunye nexabiso lokusika kufuneka lincitshiswe.

3. Ngexesha lokusika, ukuba kukho ukungcangcazela okungaqhelekanga okanye isandi, nceda unciphise isantya kunye nesixa sokusika de imeko iphucule.

4. Ukupholisa insimbi kukhethwa ukutshiza kunye nejethi yomoya, enokuphucula umphumo wokusetyenziswa kwe-milling cutter. I-Titanium alloys kunye nezinye ii-superalloys azikhuthazwa.