HSS Tap M3, M4, M5, M6, M8, M10 Drill Tap Bits

INGCACISO YEMVELISO

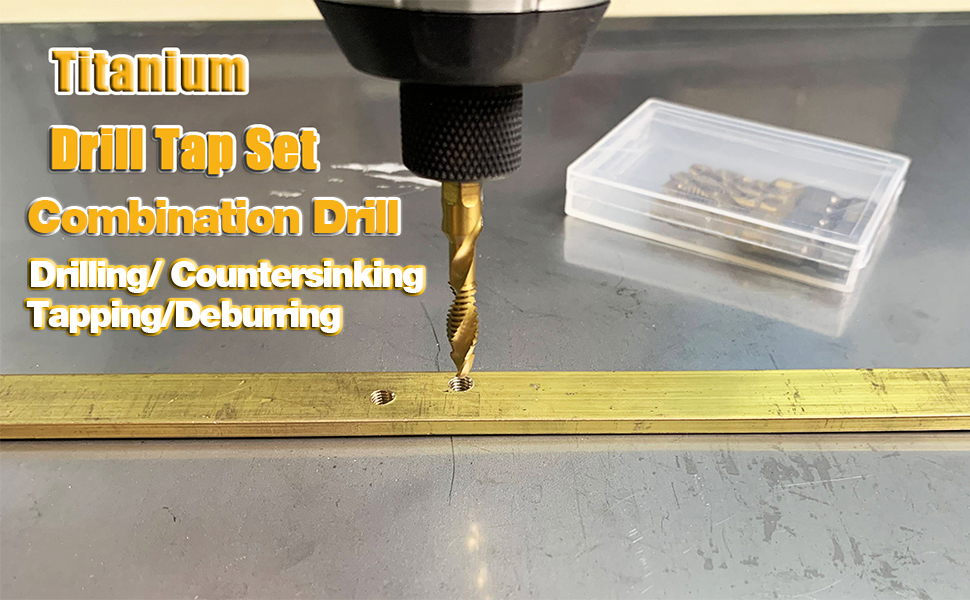

Kwisiphelo sangaphambili sempompo (impompo yomsonto) kukho i-drill bit, eyimpompo ephezulu esebenzayo (impompo yentambo) yokomba rhoqo kunye nokucofa ukugqiba ukusetyenzwa ngexesha elinye.

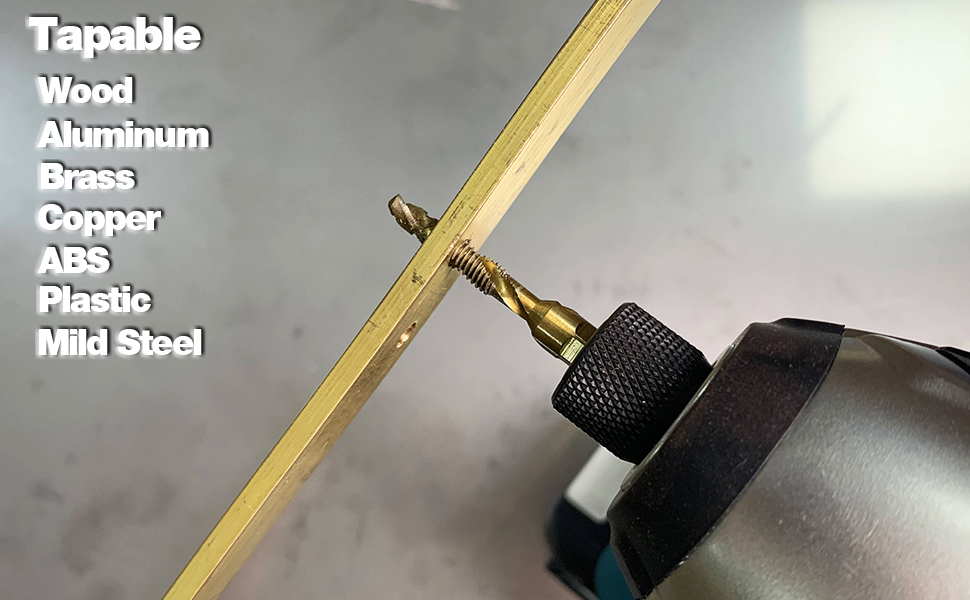

I-Speed-speed steel 4341 impahla, ifanele iplastiki, i-PVC, imithi kunye nezinye izinto.

I-Speed-Speed steel 6542 impahla, ifanelekile kwiintsimbi ezithambileyo ezifana ne-aluminium alloy, i-tin alloy, iindawo ezahlukeneyo zobhedu, kunye nentsimbi.

Isantya esiphezulu sentsimbi ye-M35, esetyenziselwa izinto ezinzima ezifana nepleyiti yentsimbi, intsimbi etyhidiweyo, i-204, i-304 yentsimbi engenasici.

INGCEBISO YOKUSETYENZISWA KWIINDAWO YOKUSEBENZA

- Ilungele ukulungiswa kwe-auto kunye nomatshini apho i-UNC idityanisiwe iingcingo ze-intshi ze-metric zichazwe.

– Zisetyenziswa kanye njenge lathe. Ngokukhawuleza, kwaye ichaneke ngokubanzi ngenxa yokuba impazamo yomntu isusiwe.

-Inokudityaniswa kwi-drill yebhentshi.

-Ifanelekile ukusetyenziswa kwi-drill ngesandla

| Uphawu | MSK | Ukwaleka | I-TiCN; uTi; Cobalt |

| Igama lemveliso | Gqoka amasuntswana eMpompo | Uhlobo lomsonto | Umsonto oQhelekileyo |

| Izinto eziphathekayo | HSS 6542/4341/4241 | Sebenzisa | I-Hand Drill |

I-ADVANTAGE

1.Ibukhali kwaye akukho burrs

Umphetho wokusika wamkela uyilo lwe-groove oluthe ngqo, olunciphisa ukunxiba ngexesha lokusika, kwaye intloko ye-cutter ibukhali kwaye ihlala ihlala njalo.

2.Ukusila ngokupheleleyo

Yonke isemhlabeni emva konyango lobushushu, kwaye umphezulu we-blade ugudile, ukuxhathisa ukususwa kwe-chip kuncinci, kwaye ukuqina kuphezulu.

3.Ukhetho olugqwesileyo lwezixhobo

Ukusebenzisa i-cobalt egqwesileyo equlethe izinto eziluhlaza, ineenzuzo zokuqina okuphezulu, ubunzima obuphezulu kunye nokumelana nokunxiba.

4.Uluhlu olubanzi lwezicelo

Iimpompo zombhobho zeCobalt eziqulathe ngqo zingasetyenziselwa ukugrumba izinto ezahlukeneyo, ezinoluhlu olupheleleyo lweemveliso.

5.Spiral groove isakhiwo

Yenziwe ngezinto zentsimbi ezinesantya esiphezulu, umphezulu ugcwele i-titanium, kwaye ubomi benkonzo bude.

| Inkcazo | Ubude bubonke(mm) | Ubude boMbhobho(mm) | Ubude befluti(mm) | Ubunzima obububo (g/pc) |

| M3 | 65 | 7.5 | 13.5 | 12.5 |

| M4 | 65 | 8.5 | 14.5 | 12.6 |

| M5 | 69 | 9.5 | 15.5 | 12.8 |

| M6 | 69 | 10 | 17.5 | 13.6 |

| M8 | 72 | 14.5 | 20 | 15.2 |

| M10 | 72 | 14.5 | 22 | 17.8 |