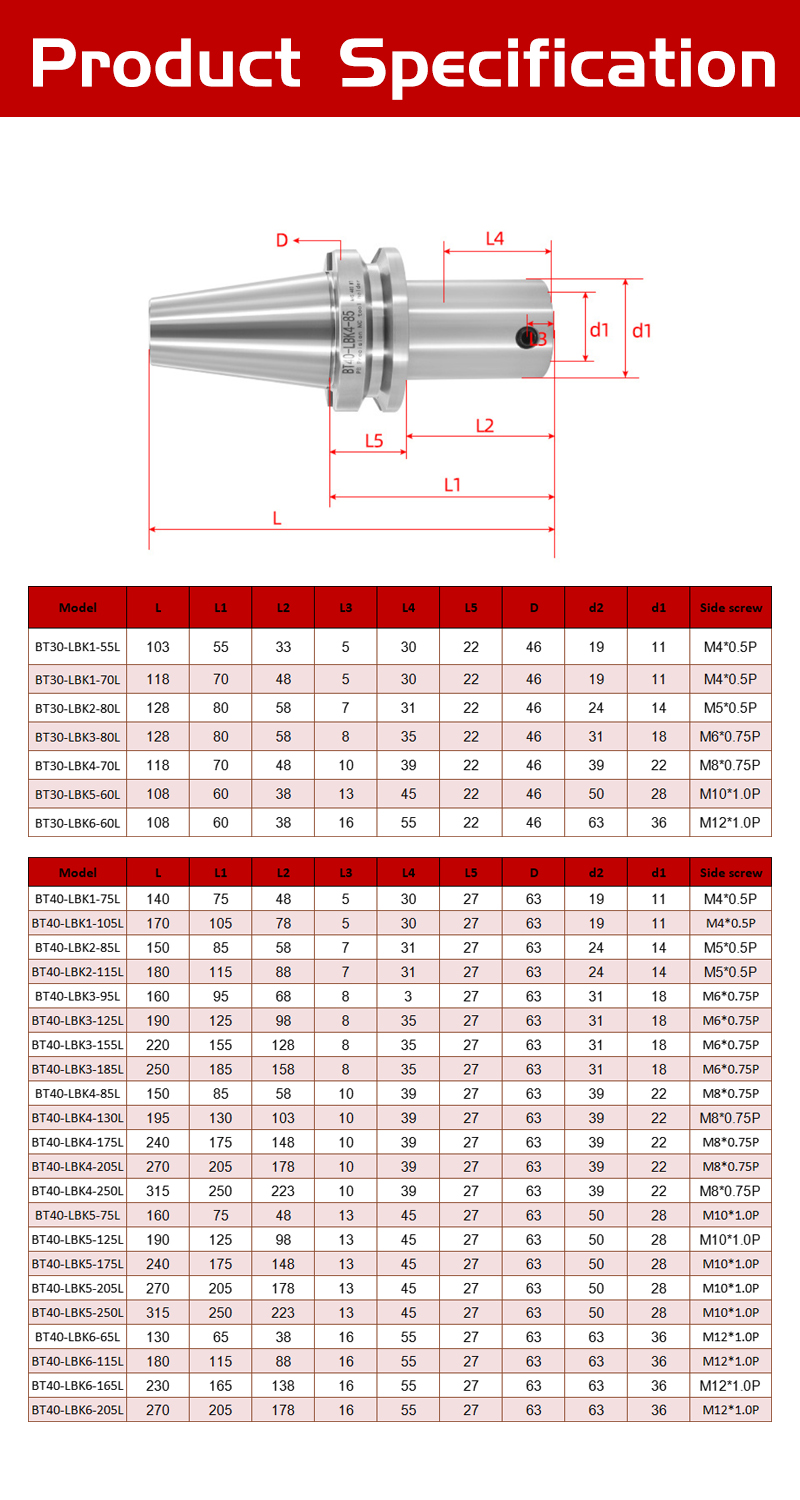

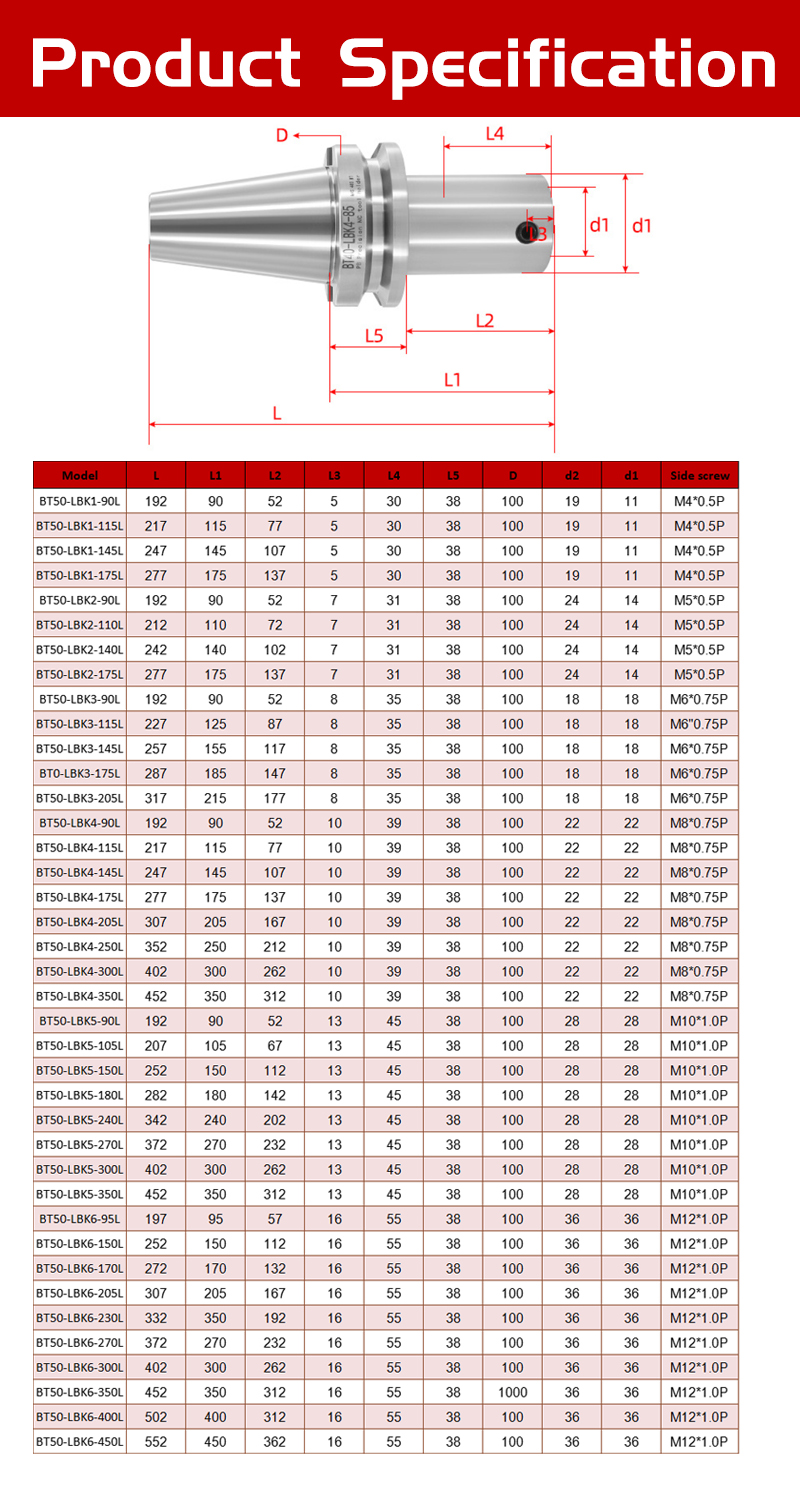

Ultra Precision BT40 BT30 BT50 LBK1 LBK2 LBK3 LBK4 LBK5 LBK6 Boring Tool Handle

Selected material 40CR

The handle body is made of 40CR material, quenched first and then formed

Ensure the hardness and toughness of the tool handle,

greatly increase the accuracy, durability and service life

Product Introduction

After grinding to ensure that the runout is within 0.005mm

Standard speed below 10,000 rpm

Fully inspected the tool handle and repaired both internally and externally

All tool holders use German testers to ensure that the taper of each product is 7:24

The outer taper meets the accuracy ≤AT3, with high appearance and good quality.

It has high thermal strength and oxygen resistance, as well as good comprehensive mechanical properties. Complete carburizing heat treatment and grinding of inner and outer diameters, strong wear resistance, and stable quality.

Each product is made from carefully selected raw materials through multiple processes such as cutting, rough turning, heat treatment, carburizing, fine grinding, and quality inspection.

The edge and arc transition chamfering process is exquisite, and the use of rivets is fast and efficient. The tool holder is clamped inside and outside in one time to achieve concentricity of the tool holder.

| Brand | MSK | Packing | Plastic box or other |

| Material | 20CrMnTi | Usage | Cnc Milling Machine Lathe |

| Customized support | OEM,ODM |

Type | NBT-ER |

What customers say about us

FAQ

Q1: Who are we?

A1: MSK (Tianjin) Cutting Technology Co., Ltd. was established in 2015. It has been growing and has passed Rheinland ISO 9001

With international advanced manufacturing equipment such as SACCKE high-end five-axis grinding center in Germany, ZOLLER six-axis tool testing center in Germany, and PALMARY machine tools in Taiwan, it is committed to producing high-end, professional, efficient and durable CNC tools.

Q2: Are you trading company or manufacturer?

A2: We are manufacturer of carbide tools.

Q3: Can you send the product to our forwarder in China?

A3: Yes, if you have a forwarder in China, we are happy to send the products to him/her.

Q4: What payment terms can be accepted?

A4: Usually we accept T/T.

Q5: Do you accept OEM orders?

A5: Yes, OEM and customization are available, we also provide custom label printing service.

Q6: Why choose us?

1) Cost control - purchase high-quality products at an appropriate price.

2) Quick response - within 48 hours, professionals will provide you with quotations and solve your doubts

consider.

3) High quality - the company always proves with a sincere heart that the products it provides are 100% high-quality, so that you have no worries.

4) After-sales service and technical guidance - we will provide one-on-one customized service and technical guidance according to your requirements.

The BT40 LBK Boring Tool Handle is a tool handle specially designed for turning and cutting operations, with the following features:

BT40 LBK Boring Tool Handle is designed with BT40 interface and can be matched with corresponding types of turning tools. The BT40 interface can provide a more stable connection to ensure processing accuracy and workpiece quality. The tool shank has good rigidity and stability and can withstand large cutting forces and vibrations, thereby providing stable cutting performance and processing quality. BT40 LBK Boring Tool Handle adopts LBK design, that is, long tool shank design, which can better meet the needs of large hole diameter and deep hole processing. The long shank design extends the length of the tool, thereby increasing its rigidity and stability. The tool handle has good wear resistance and uses high-quality materials and precision manufacturing processes to maintain good performance and lifespan over a long period of use. The BT40 LBK Boring Tool Handle is designed to be simple and easy to install and disassemble, improving work efficiency and reducing operating time. In short, BT40 LBK Boring Tool Handle has good rigidity, stability and wear resistance, and is suitable for turning and cutting processing, especially for large hole diameter and deep hole processing.