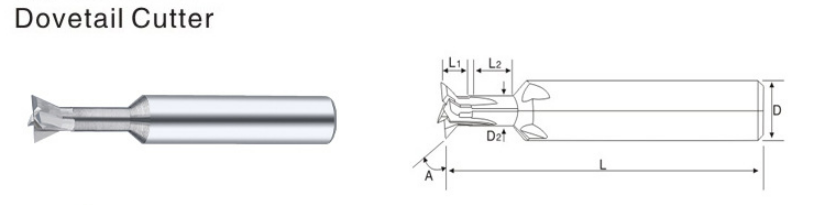

Tungsten Carbide Dovetail Milling Cutters Tool

The whole item is made of high-quality tungsten steel, with high hardness and high wear resistance. The use of high performance alloy steel material, with good seismic resistance.It is made of new fine-grained tungsten steel bars, which has high wear resistance and strength. It is a high-quality dovetail knife for high-hardness high-speed cutting applications. It can perform high-speed processing on stainless steel, aluminum alloy, cast iron and other materials below HRC55 (including HRC55). Machining, reducing the number of tool changes and improving efficiency

Advantage:

Cost-effective and we choose high-quality tungsten steel with high hardness and high wear resistance

Precision machine building, fine grinding. Precision processing, less burrs in product processing-high smoothness

Strict quality control, high precision and sharper finished products

Feature:

1. Sharp edge angles greatly improve cutting efficiency

2. Straight groove design, smooth chip evacuation without sticking to the knife

3. Reasonably avoid the air and extend the tool life

4. Strengthen the rigidity of cutting edge, and the arc edge belt is conductive to the sharper side edge and effectively remove burr.

5. The large capacity chip removal groove cuts the force, and the cutting is more fluent, achieving high efficiency machining, and the workpiece is more precise and more awesome.

| Type |

Tungsten Dovetail Milling Cutter |

Material |

Tungsten Steel |

| Workpiece Material | Stainless steel, aluminum, die steel, cast iron, aluminum alloy, alloy steel, titanium alloy, etc. | Applicable machine tool | CNC machining center, CNC machine tool, engraving machine, engraving machine, high-speed machine |

| Transport Package | Box | Flute | 3/4 |

| Coating | No | Hardness | <=55 |

|

Flute Diameter(mm) |

D2(mm) |

L2(mm) |

Flute Height(mm) |

Shank Diameter(mm) |

Total Length(mm) |

Flutes |

|

3 |

1.5 |

5 |

0.7 |

3 |

50 |

3 |

|

4 |

2 |

6 |

1 |

4 |

50 |

3 |

|

5 |

2.5 |

8 |

1.2 |

5 |

50 |

3 |

|

6 |

3 |

8 |

1.5 |

6 |

50 |

3 |

|

7 |

3.5 |

10 |

1.7 |

7 |

50 |

4 |

|

8 |

4 |

10 |

2 |

8 |

50 |

4 |

|

9 |

4.5 |

15 |

2.2 |

9 |

60 |

4 |

|

10 |

5 |

15 |

2.5 |

10 |

60 |

4 |

|

11 |

5.5 |

15 |

2.7 |

11 |

60 |

4 |

|

12 |

6 |

15 |

3 |

12 |

60 |

4 |

|

16 |

8 |

20 |

4 |

16 |

65 |

4 |

|

20 |

10 |

25 |

5 |

20 |

75 |

4 |

|

3 |

1.5 |

5 |

1.4 |

3 |

50 |

3 |

|

4 |

2 |

6 |

1.7 |

4 |

50 |

3 |

|

5 |

2.5 |

8 |

2.1 |

5 |

50 |

3 |

|

6 |

3 |

8 |

2.6 |

6 |

50 |

3 |

|

7 |

3.5 |

10 |

3 |

7 |

60 |

4 |

|

8 |

4 |

10 |

3.4 |

8 |

60 |

4 |

|

9 |

4.5 |

15 |

3.8 |

9 |

60 |

4 |

|

10 |

5 |

15 |

4.3 |

10 |

60 |

4 |

|

11 |

5.5 |

15 |

4.7 |

11 |

60 |

4 |

|

12 |

6 |

15 |

5.2 |

12 |

60 |

4 |

|

16 |

8 |

20 |

6.9 |

16 |

65 |

4 |

|

20 |

10 |

25 |

8.6 |

20 |

70 |

4 |

|

3 |

1.5 |

5 |

2.7 |

3 |

50 |

3 |

|

4 |

2 |

6 |

3.7 |

4 |

50 |

3 |

|

5 |

2.5 |

8 |

4.6 |

5 |

50 |

3 |

|

6 |

3 |

8 |

5.5 |

6 |

50 |

3 |

|

7 |

3.5 |

10 |

6.5 |

7 |

60 |

4 |

|

8 |

4 |

10 |

7.4 |

8 |

60 |

4 |

|

9 |

4.5 |

15 |

8.3 |

9 |

60 |

4 |

|

10 |

5 |

15 |

9.3 |

10 |

60 |

4 |

|

11 |

5.5 |

15 |

10.2 |

11 |

60 |

4 |

|

12 |

6 |

15 |

11.1 |

12 |

60 |

4 |

|

16 |

8 |

20 |

14.9 |

16 |

65 |

4 |

|

20 |

10 |

25 |

18.6 |

20 |

75 |

4 |

Use:

Widely used in many fields

Aviation Manufacturing

Machine Production

Car manufacturer

Mold making

Electrical Manufacturing

Lathe processing