ER11 ER20 ER25 ER32 ER40 Collet Sets for Lathe

PRODUCT DESCRIPTION

1.Grinding treatment process, bright, wear-resistant and heat-resistant, high precision

2.65 high hardness spring steel, high elasticity, high tensile strength, good clamping performance

3.Two fine turning processes, high polishing, anti-rust design, high elasticity

RECOMMENDATION FOR USE IN WORKSHOPS

– After thermal processing and high temperature treatment, the strength is relatively high, and it has certain flexibility and plasticity.

– High-quality spring steel elastic design, high elasticity, strong clamping force, not easy to deform after repeated use.

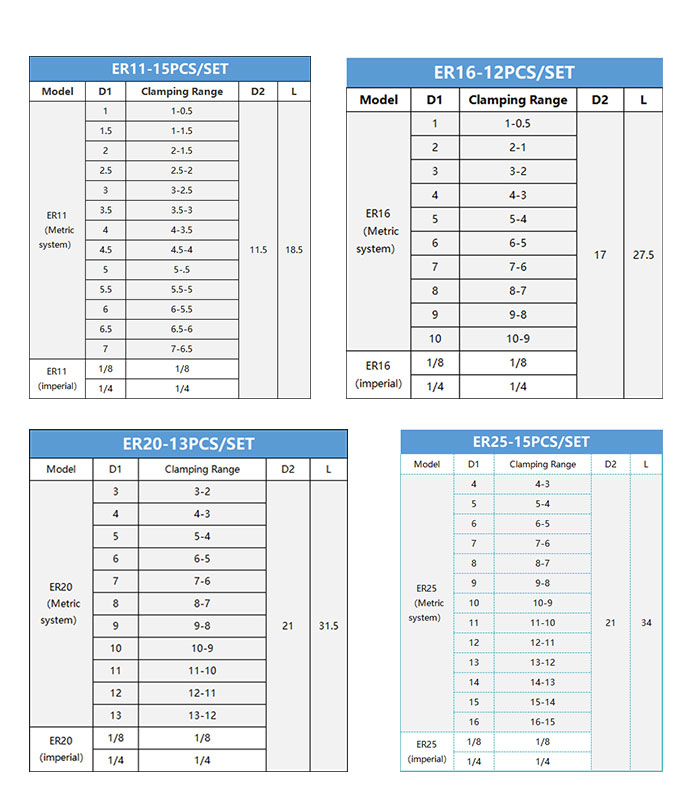

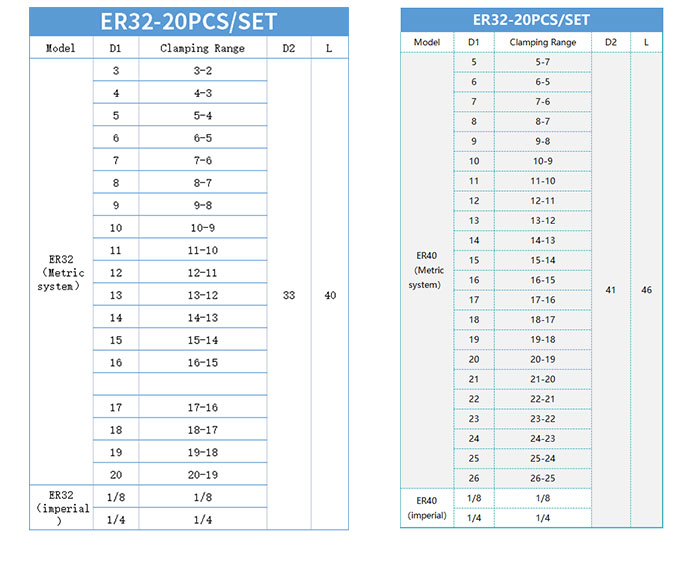

– ER collet (metric/imperial) series set, there are 6 sets of specifications, you can choose any one or multiple sets of sets according to actual needs, and at the same time meet the clamps of drills, milling cutters, dumpling cutters and other tools of various specifications Support, more convenient to use, more cost-effective.

| Brand | MSK | Stock | TiYes |

| Product Name | Collets | Precision | 0.008mm |

| Material | 65Mn | Applicable machine tools | Milling machine Boring machine Lathe |

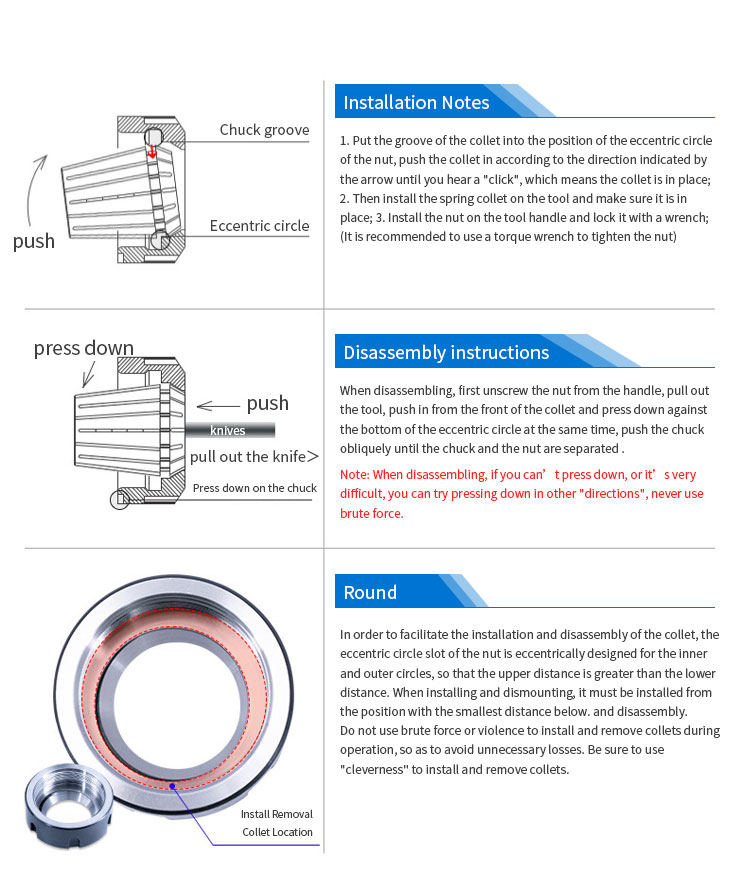

INSTALLATION NOTES

1. Put the groove of the collet into the position of the eccentric circle of the nut, push the collet in according to the direction indicated by the arrow until you hear a "click", which means the collet is in place;

2. Then install the spring collet on the tool and make sure it is in place; 3. Install the nut on the tool handle and lock it with a wrench;

(It is recommended to use a torque wrench to tighten the nut).