Superior HSS M35 DIN338cobalt Drill Bits for Solid Steel

Feature:

The straight shank twist drill is the most widely used hole processing tool. The diameter range is usually 0.25 to 80 mm. It is mainly composed of a working part and a shank. The working part has two spiral grooves.

| Model | Blade diameter(mm) | Overall length(mm) |

| 2*160mm | 2*160 | Standard |

| 2.5*160mm | 2.5*160 | Standard |

| 2.8*160mm | 2.8 | Standard |

| 3*160mm | 3*160 | Standard |

| 3.2*160mm | 3.2 | Standard |

| 3.5*160mm | 3.5*160 | Standard |

| 4*160mm | 4*160 | Standard |

| 4.2*160mm | 4.2 | Standard |

| 4.5*160mm | 4.5*160 | Standard |

| 5*160mm | 5*160 | Standard |

| 5.2*160mm | 5.2 | Standard |

| 5.5*160mm | 5.5*160 | Standard |

| 6*160mm | 6*160 | Standard |

| 6.5*160mm | 6.5*160 | Standard |

| 2*200mm | 2* | Standard |

| 2.5*200mm | 2.5* | Standard |

| 3*200mm | 3* | Standard |

| 3.2*200mm | 3.2mm | Standard |

| 3.5*200mm | 3.5* | Standard |

| 3.8*200mm | 3.8 | Standard |

| 4*200mm | 4* | Standard |

| 4.2*200mm | 4.2mm | Standard |

| 4.5*200mm | 4.5* | Standard |

| 5*200mm | 5* | Standard |

| 5.2*200mm | 5.2mm | Standard |

| 5.5*200mm | 5.5* | Standard |

| 6*200mm | 6* | Standard |

| 6.5*200mm | 6.5* | Standard |

| 7*200mm | 7* | Standard |

| 7.5*200mm | 7.5* | Standard |

| 8*200mm | 8* | Standard |

| 8.5*200mm | 8.5* | Standard |

| 9*200mm | 9* | Standard |

| 9.5*200mm | 9.5* | Standard |

| 9.8*200mm | 9.8 | Standard |

| 10*200mm | 10* | Standard |

| 10.2*200mm | 10.2 | 200 |

| 10.5*200mm | 10.5* | Standard |

| 3*250mm | 3*250 | Standard |

| 3.5*250mm | 3.5*250 | Standard |

| 4*250mm | 4*250 | Standard |

| 4.5*250mm | 4.5*250 | Standard |

| 5*250mm | 5*250 | Standard |

| 5.5*250mm | 5.5*250 | Standard |

| 6*250mm | 6*250 | Standard |

| 6.5*250mm | 6.5*250 | Standard |

| 7*250mm | 7*250 | Standard |

| 7.5*250mm | 7.5*250 | Standard |

| 8*250mm | 8*250 | Standard |

| 9*250mm | 9*250 | Standard |

| 10*250mm | 10*250 | Standard |

| 11*250mm | 11*250 | Standard |

| 12*250mm | 12*250 | Standard |

| 3*300mm | 3 | Standard |

| 4*300mm | 4.0MM | Standard |

| 5*300mm | 5.0MM | Standard |

| 5.5*300mm | 5.5、 | Standard |

| 6*300mm | 6.0MM | Standard |

| 6.5*300mm | 6.5 | Standard |

| 7*300mm | 7.0MM | Standard |

| 7.5*300mm | 7.5、 | Standard |

| 8*300mm | 8.0MM | Standard |

| 8.5*300mm | 8.5 | 300 |

| 9*300mm | 9.0MM | Standard |

| 9.5*300mm | 9.5 | 300 |

| 10*300mm | 10.0MM | Standard |

| 10.5*300mm | 10.5 | 300 |

| 11*300mm | 11.0MM | Standard |

| 11.5*300mm | 11.5 | 300 |

| 12*300mm | 12.0MM | Standard |

| 12.5*300mm | 12.5 | 12.53 |

| 13*300mm | 13.0MM | Standard |

| 13.5*300mm | 13.5、 | Standard |

| 14*300mm | 14.0MM | Standard |

| 14.5*300mm | 14.5 | |

| 15*300mm | 15 | |

| 15.5*300mm | 15.5 | |

| 16*300mm | 16 | |

| 4*350mm | 4MM | Standard |

| 5*350mm | 5MM | Standard |

| 6*350mm | 6MM | Standard |

| 7*350mm | 7MM | Standard |

| 7.5*350mm | 7.5. | Standard |

| 8*350mm | 8MM | Standard |

| 8.5*350mm | 8.5. | Standard |

| 9*350mm | 9MM | Standard |

| 9.5*350mm | 9.5。 | Standard |

| 10*350mm | 10MM | Standard |

| 10.5*350mm | 10.5 | 350 |

| 11*350mm | 11MM | Standard |

| 11.5*350mm | 11.5。 | Standard |

| 12*350mm | 12MM | Standard |

| 4*400mm | 4mm | Standard |

| 5*400mm | 5mm | Standard |

| 5.5*400mm | 5.5 | Standard |

| 6*400mm | 6mm | Standard |

| 6.5*400mm | 6.5, | Standard |

| 7*400mm | 7mm | Standard |

| 7.5*400mm | 7.5, | Standard |

| 8*400mm | 8mm | Standard |

| 8.5*400mm | 8.5 | 400 |

| 9*400mm | 9mm | Standard |

| 9.5*400mm | 9.5, | Standard |

| 10*400mm | 10mm | Standard |

| 10.5*400mm | 10.5, | Standard |

| 11*400mm | 11mm | Standard |

| 11.5*400mm | 11.5, | Standard |

| 12*400mm | 12mm | Standard |

| 12.5*400mm | 12.5, | Standard |

| 13*400mm | 13mm | Standard |

| 13.5*400mm | 13.5 | |

| 14*400mm | 14 | |

| 14.5*400mm | 14.5- | |

| 15*400mm | 15 | |

| 15.5*400mm | 15.5- | |

| 16*400mm | 16 | |

| 5*450mm | 5 | Standard |

| 6*450mm | 6 | Standard |

| 7*450mm | 7 | Standard |

| 8*450mm | 8 | Standard |

| 9*450mm | 9 | Standard |

| 10*450mm | 10 | Standard |

| 11*450mm | 11 | Standard |

| 12*450mm | 12 | Standard |

| 13*450mm | 13 | Standard |

| 14*450mm | 14 | Standard |

| 5*500mm | 5 | Standard |

| 6*500mm | 6 | Standard |

| 7*500mm | 7 | Standard |

| 7.5*500 | 7.5 | Standard |

| 8*500mm | 8 | Standard |

| 8.5*500mm | 8.5 | 500 |

| 9*500mm | 9 | Standard |

| 9.5*500mm | 9.5 | Standard |

| 10*500mm | 10 | Standard |

| 10.5*500mm | 10.5 | Standard |

| 11*500mm | 11 | Standard |

| 11.5*500mm | 11.5 | Standard |

| 12*500mm | 12 | Standard |

| 12.5*500 | 12.5 | Standard |

| 13*500mm | 13 | Standard |

| 13.5*500 | 13.5 | Standard |

| 14*500mm | 14 | Standard |

| 8*550mm | 8 | 550 |

| 9*550mm | 9 | 550 |

| 10*550mm | 10 | 550 |

| 11*550mm | 11 | 550 |

| 12*550mm | 12 | 550 |

| 8*600mm | 8 | 600 |

| 9*600mm | 9 | 600 |

| 10*600mm | 10 | 600 |

| 11*600mm | 11 | 600 |

| 12*600mm | 12 | 600 |

| 13*600mm | 13 | 600 |

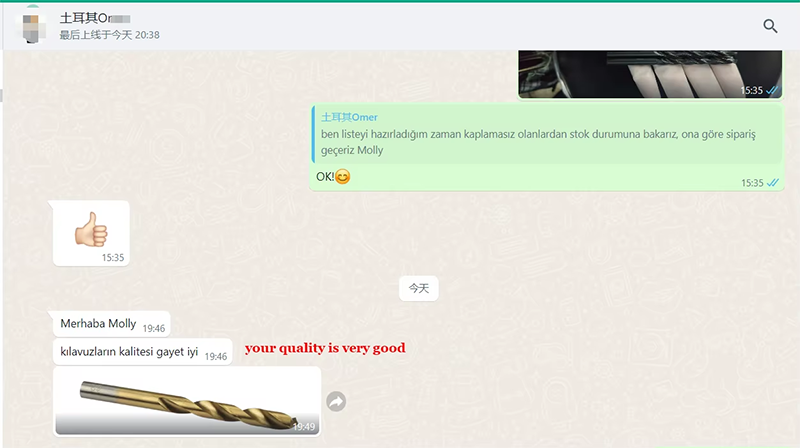

Why Choose Us

Factory Profile

About Us

FAQ

Q1: who are we?

A1: Founded in 2015, MSK (Tianjin) Cutting Technology CO.Ltd has grown continuously and passed Rheinland ISO 9001

authentication.With German SACCKE high-end five-axis grinding centers, German ZOLLER six-axis tool inspection center, Taiwan PALMARY machine and other international advanced manufacturing equipment, we are committed to producing high-end,professional and efficient CNC tool.

Q2: Are you trading company or manufacturer?

A2: We are the factory of carbide tools.

Q3: Can you send products to our Forwarder in China?

A3: Yes,if you have Forwarder in China,we will glad to send products to him/her.Q4: What terms of payment are acceptable?

A4: Normally we accept T/T.

Q5: Do you accept OEM orders?

A5: Yes, OEM and customization are available, and we also provide label printing service.

Q6: Why should you choose us?

A6:1) Cost control - purchasing high-quality products at an appropriate price.

2) Quick response - within 48 hours, professional personnel will provide you with a quote and address your concerns.

3) High quality - The company always proves with sincere intention that the products it provides are 100% high-quality.

4) After sales service and technical guidance - The company provides after-sales service and technical guidance according to customer requirements and needs.