Tungsten Carbide Rotary Burr Bits For Metal

TLHALOSO EA SEHLAHISOA

Lifaele tsa rotary tsa Carbide li sebelisoa haholo bakeng sa lisebelisoa tsa motlakase kapa lisebelisoa tsa moea, hape li ka kenngoa lisebelisoa tsa mochini.

TŠEBELETSO

Carbide rotary file ke sesebelisoa sa bohlokoahali se tsoetseng pele bakeng sa li-fitters le lisebelisoa tsa ho sila. E khetholloa ka ho nkela sebaka sa lebili le lenyenyane la ho sila ka letsoho ntle le tšilafalo ea lerōle, bophelo ba tšebeletso bo lekana le makholo a makholo a mabili a manyenyane a sila a nang le molamu, 'me katleho ea ts'ebetso e eketseha ka makhetlo a fetang 5. Ho bonolo ho e laola, e bonolo ho e sebelisa, e bolokehile ebile e ka tšeptjoa, e fokotsa haholo litšenyehelo tse boima tsa mosebetsi oa matsoho le tlhahiso.

Lisebelisoa: Lifaele tsa rotary tsa Carbide li sebelisoa haholo, 'me li sebelisoa ho sebetsa le ho etsa lisebelisoa tsa abrasive. Ho cheka li-chamfering, ho pota-pota le li-grooves bakeng sa mesebetsi e sa tloaelehang ea mechine, ho hloekisa likarolo tsa flash ea li-castings, forgings le likarolo tsa welding; ho phethoa ha liphaephe, limathi tsa li-impeller, le bonono le mesebetsi ea matsoho ea ho betla lisebelisoa tsa tšepe le tse se nang tšepe (lesapo, jade, lejoe) .

TSEBISO

1. Pele o sebetsa, ka kopo bala lebelo la ts'ebetso ho khetha lebelo le loketseng la lebelo (ka kopo, sheba maemo a khothalletsoang a ho qala). Lebelo le tlase le tla ama bophelo ba sehlahisoa le sephetho sa bokaholimo, athe lebelo le tlase le tla ama ho tlosoa ha chip ea sehlahisoa, puisano ea mochini le ho roala ha sehlahisoa pele ho nako.

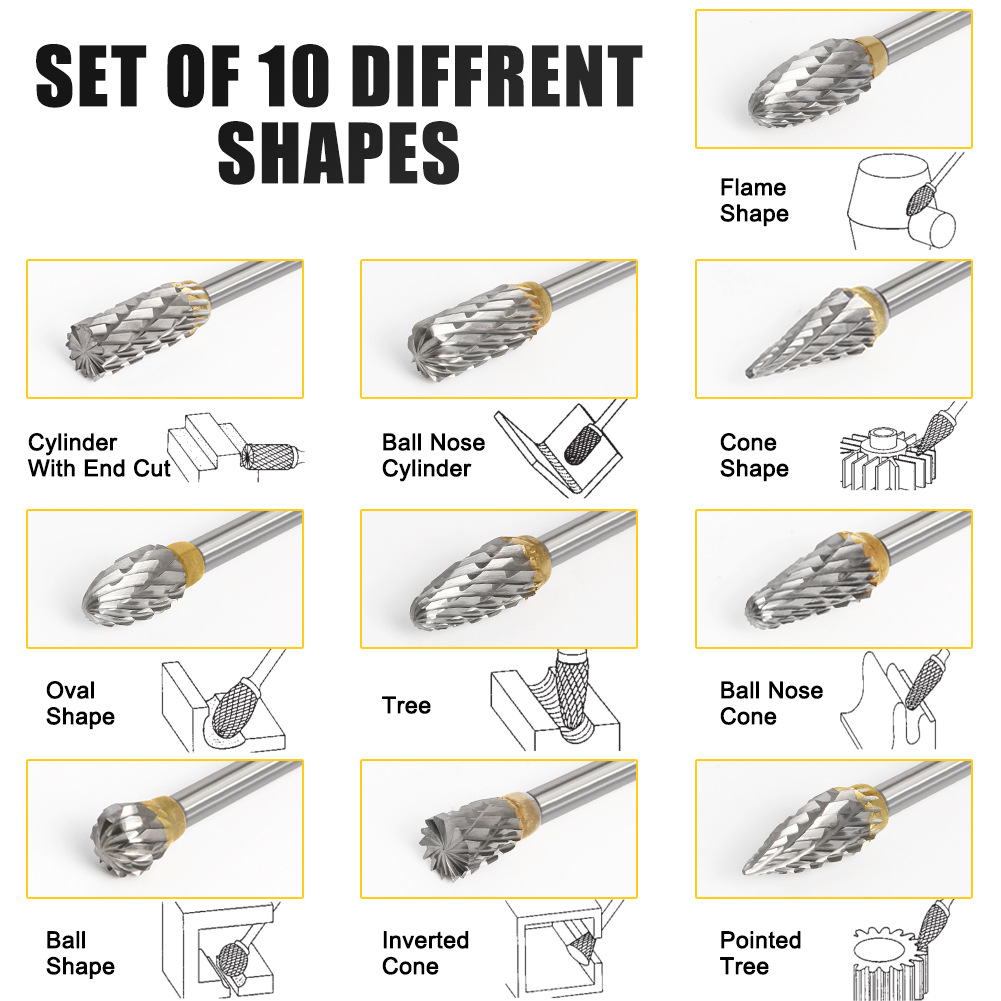

2. Khetha sebopeho se loketseng, bophara le profil ea leino bakeng sa ts'ebetso e fapaneng.

3. Khetha grinder ea motlakase e loketseng e nang le ts'ebetso e tsitsitseng.

4. Bolelele ba karolo e pepeneneng ea sephethephethe se kentsoeng ka har'a chuck ke boholo ba 10mm. (Ntle le sesebelisoa sa katoloso, lebelo le fapane)

5. Idling pele o sebelisoa ho etsa bonnete ba concentricity e ntle ea faele ea rotary, eccentricity le vibration tla baka ho apara pele ho nako le workpiece senya.

6. Ha ho bohlale ho sebelisa khatello e ngata haholo nakong ea tšebeliso. Khatello e ngata haholo e tla fokotsa bophelo le katleho ea sesebelisoa.

7. Hlahloba hore na workpiece le grinder ea motlakase li koaletsoe ka nepo le ka thata pele li sebelisoa.

8. Apara likhalase tse sireletsang tse loketseng ha u sebelisa.