Tungsten Carbide Flow Drill Bit

TLHALOSO EA SEHLAHISOA

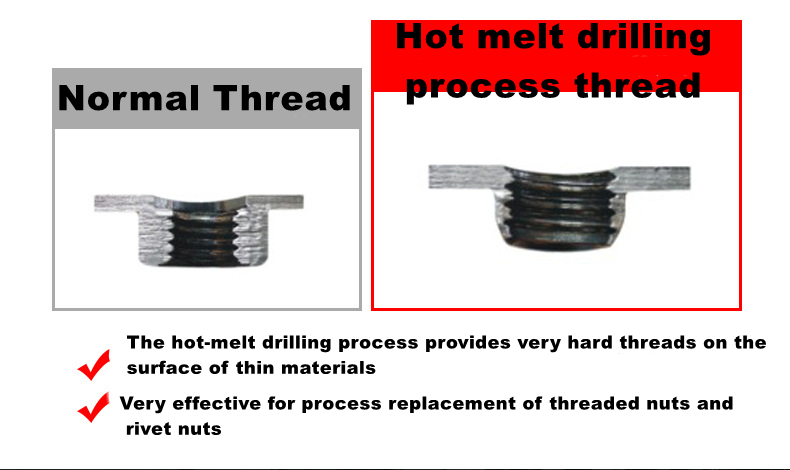

Molao-motheo oa ho cheka ho chesang ho qhibiliha

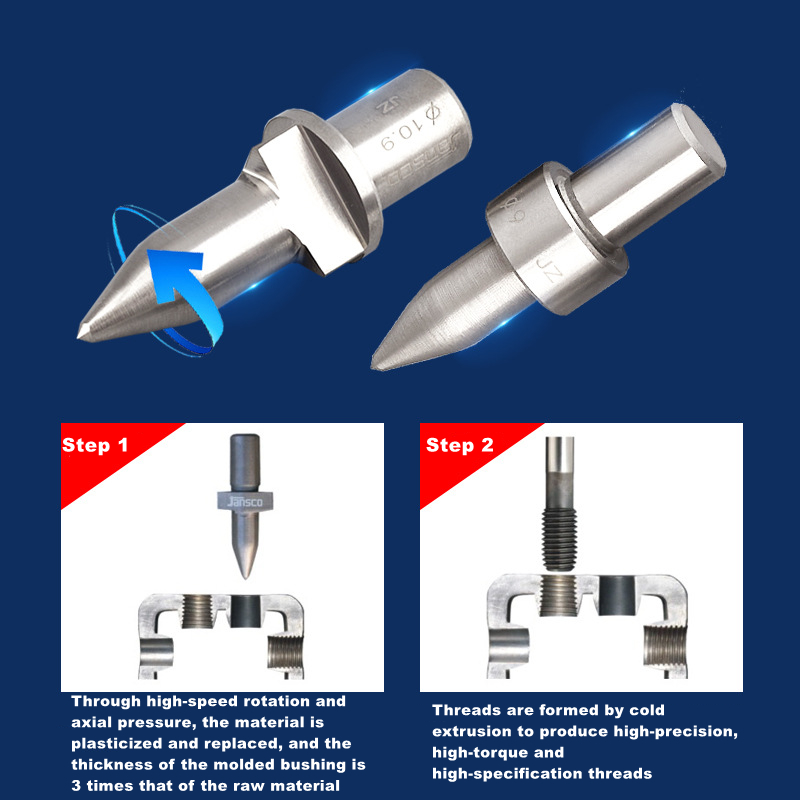

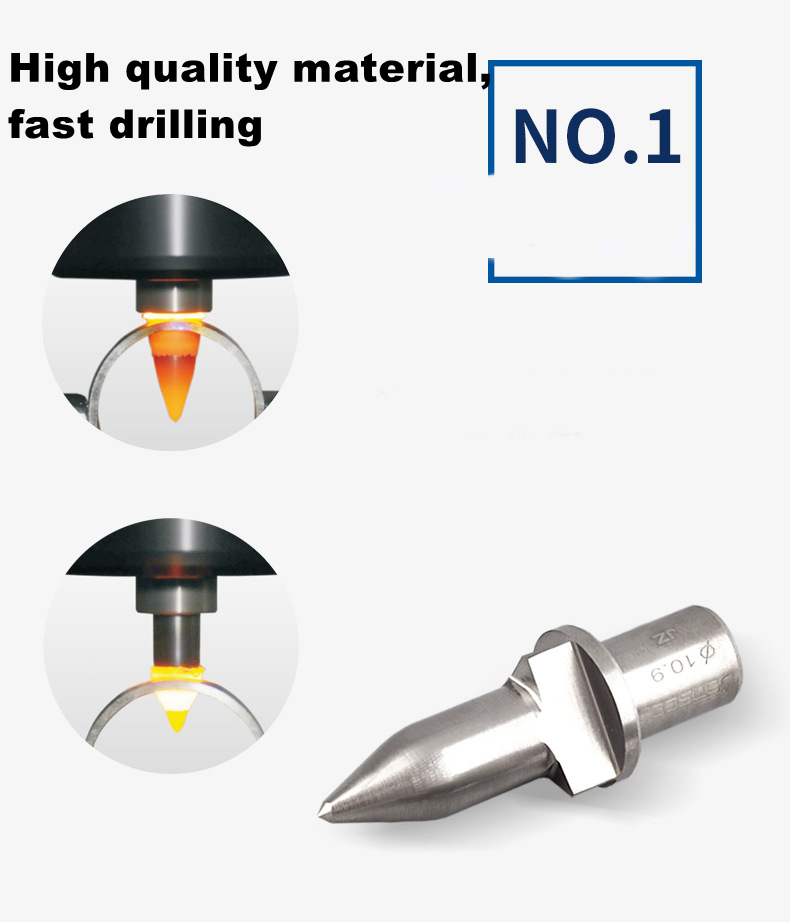

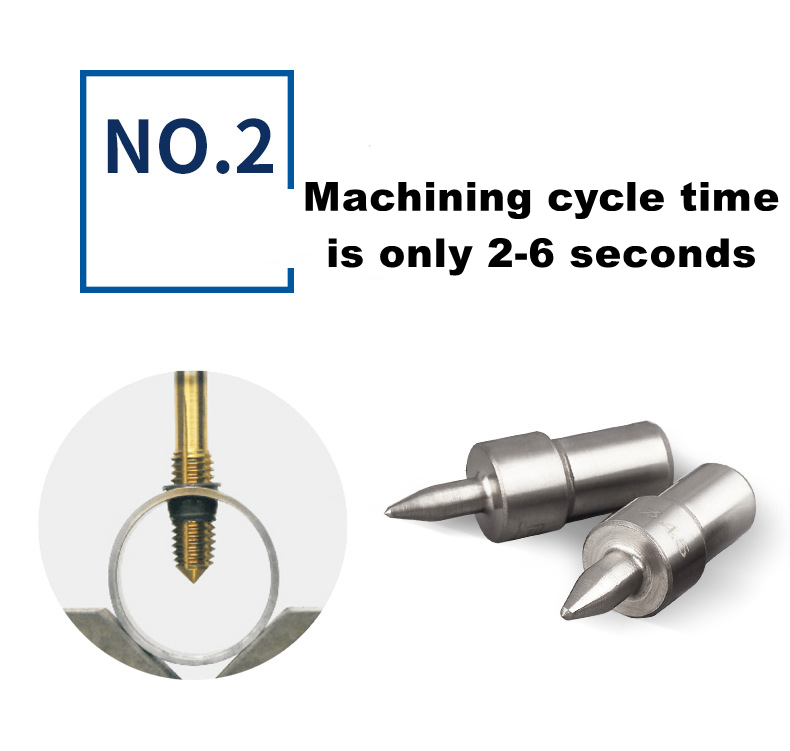

The hot-melt drill e hlahisa mocheso ka ho potoloha ka lebelo le phahameng le axial pressure friction ho polasetiki le ho nkela thepa sebaka. Ka nako e ts'oanang, e phunya le ho etsa sehlahla ka makhetlo a ka bang 3 ho feta botenya ba thepa e tala, 'me e ntša le ho penya ka pompong ho e etsa holim'a thepa e tšesaane. Likhoele tse nepahetseng, tse matla haholo.

KHOTHATSO EA HO SEBELISA LITHUPANG

Mohato oa pele: polasetiki ea thepa ka ho potoloha ka lebelo le phahameng le khatello ea axial. Botenya ba bushing e bōpiloeng ke makhetlo a 3 a thepa e tala.

Mohato oa bobeli: khoele e entsoe ka extrusion e batang ho hlahisa boleng bo phahameng, torque e phahameng le e phahameng haholo.n likhoele

| Brand | MSK | Ho roala | No |

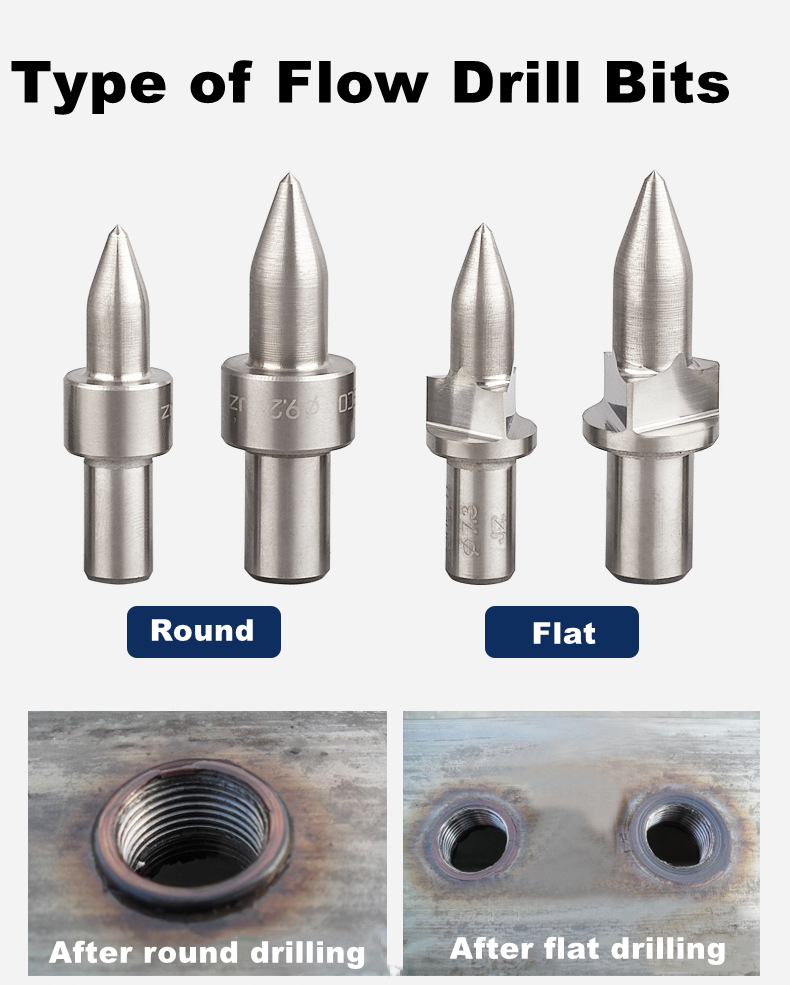

| Lebitso la Sehlahiswa | Thermal Friction Drill Bit Bit Set | Mofuta | Mofuta o bataletseng / o chitja |

| Lintho tse bonahalang | Carbide Tungsten | Sebelisa | Ho phunya |

TŠEBELETSO

Litlhokomelo bakeng sa tšebeliso ea li-drill tse chesang tse chesang:

1. Workpiece lintho tse bonahalang: hot-qhibidiha ho cheka ho loketse ho sebetsana le lisebelisoa tse sa tšoaneng tsa tšepe tse nang le bophara ba 1.8-32mm le botenya ba lerako la 0.8-4mm, joalo ka tšepe, tšepe e bonolo, tšepe e sa hloekang, titanium, aluminium, koporo, koporo, koporo (Zn content ka tlase ho 40%), aluminium e ka tlaase ho 40%, aluminium e ka tlaase ho feta 0. khutsufatsa bophelo ba ho cheka ho chesa.

2. Sekhahla se chesang se chesang: Ha mochine o chesang o chesang o sebetsa, mocheso o phahameng oa likhato tse fetang 600 o hlahisoa hang-hang. Sekhahla se khethehileng sa ho qhibiliha se chesang se ka lelefatsa bophelo ba tšebeletso ea ho cheka ho chesang ho chesang, ho ntlafatsa boleng ba bokahare ba ka hare ho silinda, le ho hlahisa sebopeho se hloekileng le se khotsofatsang. Ho kgothaletswa ho eketsa palo e nyane ea peista e chesang e chesang holim'a sesebelisoa bakeng sa likoti tse ling le tse ling tse 2-5 tse entsoeng ka tšepe e tloaelehileng ea carbon; bakeng sa lisebelisoa tsa tšepe tse sa hloekang, bakeng sa sekoti se seng le se seng se phuntsoeng, eketsa pente e chesang e qhibilihisang ka letsoho; ha thepa e teteana le ho feta, e phahamisa makhetlo a mangata.

3. Shank le chuck ea hot melt drill: Haeba ho se na metsi a khethehileng a mocheso, sebelisa moea o hatelitsoeng ho pholile.

4. Lisebelisoa tsa mochine oa ho phunya: hafeela mechine e fapa-fapaneng ea ho phunya, mechine ea ho cheka le litsi tsa machining tse nang le lebelo le matla a loketseng li loketse ho cheka ho qhibiliha ho chesang; Botenya ba thepa le phapang ea thepa ka boeona kaofela li ama boikemisetso ba lebelo la ho potoloha.

5. Likoti tse entsoeng esale pele: Ka ho phunya lesoba le lenyenyane la ho qala, deformation ea workpiece e ka qojoa. Likoti tse entsoeng esale pele li ka fokotsa matla a axial le bophahamo ba silindara, hape li ka hlahisa moeli o bataletseng qetellong ea silinda ho qoba ho kobeha ha li-workpieces tse tšesaane (tse ka tlase ho 1.5mm).

6. Ha u tlanya, sebelisa oli ea ho phunya: ho kgothaletswa ho sebelisa lipompo tsa extrusion, tse sa thehoang ka ho khaola empa ka extrusion, kahoo li na le matla a phahameng a matla le boleng ba torsion. Hape hoa khoneha ho sebelisa lipompo tse tloaelehileng tsa ho itšeha, empa ho bonolo ho khaola cylinder, 'me bophara ba mochine o chesang o chesang o fapane' me o hloka ho etsoa ka thoko.

7. Tlhokomelo ea ho cheka hot-melt: Ka mor'a hore mochine o chesang o chesang o sebelisoe ka nako e itseng, bokaholimo bo tla apara, 'me litšila tse ling tsa hot-mellt kapa li-workpiece li tla kopanngoa le' mele oa sehahi. Tobetsa boro e qhibilihang ka har'a chuck ea lathe kapa mochini o silang, 'me u o sile ka peista ea abrasive. U se ke ua ela hloko polokeho.