Joalo ka sesebelisoa se tloaelehileng sa ho sebetsana le likhoele tse ka hare, lipompo li ka aroloa ka lipompo tsa spiral groove, lipompo tse sekametseng moeling, lipompo tse otlolohileng tsa groove le likhoele tsa likhoele ho latela libopeho tsa tsona, 'me li ka aroloa ka lipompo tsa letsoho le lipompo tsa mochini ho latela tikoloho ea ts'ebeliso. E arotsoe ka lipompo tsa metric, tsa Amerika le tsa borena. Na u li tseba kaofela?

01 Tlanya tlhophiso

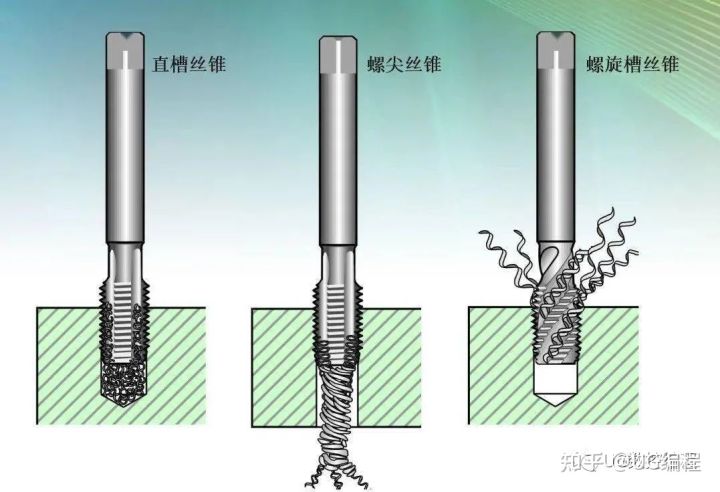

(1) Ho khaola lipompo

1) Tlanya e otlolohileng ya lekolilo: e sebelisetsoang ho sebetsana le likoti le masoba a foufetseng, li-chips tsa tšepe li teng ka har'a pompong ea pompong, boleng ba khoele e entsoeng ha bo phahameng, 'me e sebelisoa haholo bakeng sa ho sebetsana le lisebelisoa tse khutšoanyane tsa chip, tse kang tšepe ea grey cast, joalo-joalo.

2) Thepa ea spiral groove: e sebelisetsoa ho sebetsana le lesoba le sa boneng ka botebo ba lesoba le ka tlase ho kapa ho lekana le 3D, lithapo tsa tšepe li ntšoa ka har'a spiral groove, 'me boleng ba khoele bo phahame.

10 ~ 20 ° helix angle tap e ka sebetsana le botebo ba khoele ka tlase ho kapa ho lekana le 2D;

28 ~ 40 ° helix angle tap e ka sebetsana le botebo ba khoele ka tlase ho kapa ho lekana le 3D;

Thepa ea 50 ° helix angle e ka sebetsana le botebo ba khoele ka tlase ho kapa ho lekana le 3.5D (boemo bo khethehileng ba ho sebetsa 4D).

Maemong a mang (lisebelisoa tse thata, molumo o moholo, joalo-joalo), e le ho fumana matla a betere a leino, ho sebelisoa pompo ea lekolilo ea helical ho etsa mochini ka masoba.

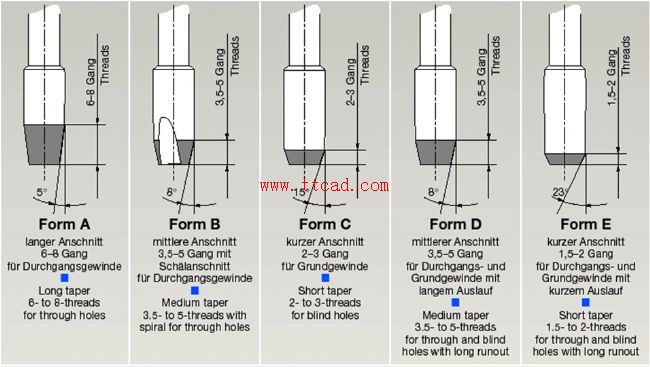

3) Thepa ea ntlha ea spiral: hangata e sebelisoa feela ka masoba, karo-karolelano ea bolelele ba bophara e ka fihla ho 3D ~ 3.5D, li-chips tsa tšepe li lahleloa ho ea tlase, torque ea ho itšeha e nyane, 'me boleng ba bokaholimo ba khoele e entsoeng ka mochini bo phahameng, bo tsejoang hape e le the angle angle tap kapa apex tap.

Ha u seha, hoa hlokahala ho etsa bonnete ba hore likarolo tsohle tsa ho itšeha li kenelletse, ho seng joalo ho phunya meno ho tla etsahala.

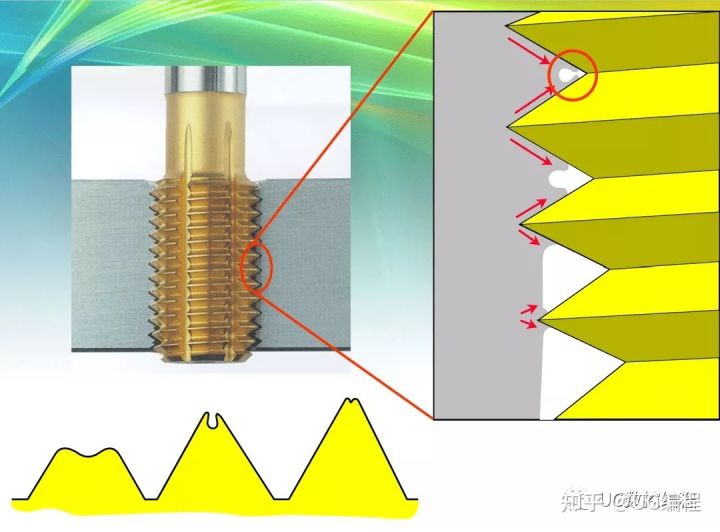

(2) Tlanya ea Extrusion

E ka sebelisoa bakeng sa ho sebetsa ka likoti le likoti tse foufetseng, 'me sebopeho sa leino se thehoa ke deformation ea polasetiki ea thepa, e ka sebelisoang feela bakeng sa ho sebetsana le lisebelisoa tsa polasetiki.

Likarolo tsa eona tsa mantlha:

1) Sebelisa deformation ea polasetiki ea workpiece ho sebetsana le khoele;

2) Sebaka sa sefapano sa pompong se seholo, matla a phahame, 'me ha ho bonolo ho senya;

3) Lebelo la ho itšeha le ka ba holimo ho feta la lipompo tsa ho itšeha, 'me tlhahiso e boetse e eketseha ka tsela e nepahetseng;

4) Ka lebaka la mokhoa o batang oa extrusion, lisebelisoa tsa mochine oa khoele e entsoeng li ntlafatsoa, ho ba le boima bo phahameng, 'me matla a khoele, ho hanyetsa ho roala le ho hanyetsa kutu hoa ntlafatsoa;

5) Machining a se nang Chipless.

Mefokolo ea eona ke:

1) e ka sebelisoa feela ho sebetsa thepa ea polasetiki;

2) Theko ea tlhahiso e phahame.

Ho na le mefuta e 'meli ea sebopeho:

1) Lipompo tsa Extrusion ntle le li-grooves tsa oli li sebelisoa feela bakeng sa machining a otlolohileng a masoba a foufetseng;

2) Lipompo tsa extrusion tse nang le li-grooves tsa oli li loketse maemo ohle a ho sebetsa, empa hangata lipompo tse nyane tsa bophara ha li etse moralo oa li-groove tsa oli ka lebaka la mathata a tlhahiso.

(1) Litekanyo

1) Bolelele ka kakaretso: Ela hloko maemo a mang a ho sebetsa a hlokang ho lelefatsa ka mokhoa o khethehileng

2) Bolelele ba slot: feta

3) Shank: Hona joale, litekanyetso tse tloaelehileng tsa shank ke DIN (371/374/376), ANSI, JIS, ISO, joalo-joalo Ha u khetha, ela hloko kamano e lumellanang le shank ea ho tlanya.

(2) Karolo e khoele

1) Ho nepahala: E khethoa ka mokhoa o khethehileng oa khoele. Tekanyo ea metric ea ISO1/2/3 e lekana le boemo ba naha ea H1/2/3, empa hoa hlokahala ho ela hloko litekanyetso tsa taolo ea ka hare ea moetsi.

2) Tlanya ea ho itšeha: Karolo e sehang ea pompo e thehile karolo ea mokhoa o tsitsitseng. Ka kakaretso, ha pompo e sehang nako e telele, bophelo ba pompo bo ntlafala.

3) Meno a ho lokisa: E phetha karolo ea ho thusa le ho lokisoa, haholo-holo boemong bo sa tsitsang ba tsamaiso ea ho tlanya, meno a ho lokisa a mangata, ho ba le khanyetso e kholoanyane ea ho otla.

(3) Likolutu tsa chip

1. Mofuta oa Groove: E ama ho thehoa le ho lokolloa ha li-filings tsa tšepe, tseo hangata e leng lekunutu la ka hare la moetsi e mong le e mong.

2. Rake angle le liphallelo angle: ha pompo e eketseha, pompo e fetoha bohale, e ka fokotsang haholo ho itšeha ho hanyetsa, empa matla le botsitso ba ntlha ea leino li fokotseha, 'me lehlakoreng la liphallelo ke lehlakoreng la liphallelo.

3. Palo ea li-grooves: palo ea li-grooves e eketseha 'me palo ea ho itšeha e eketseha, e ka ntlafatsang bophelo ba pompong ka katleho; empa e tla hatella sebaka sa ho tlosa chip, se seng hantle bakeng sa ho tlosa chip.

03 Thepa ea thepa le ho roala

(1) Thepa ea pompong

1) Tool steel: E sebelisoa haholo bakeng sa lipompo tsa incisor ka letsoho, tse sa tloaelehang hajoale.

2) Cobalt e se nang lebelo le phahameng la tšepe: Hajoale, e sebelisoa haholo joalo ka lisebelisoa tsa pompo, joalo ka M2 (W6Mo5Cr4V2, 6542), M3, joalo-joalo, mme khoutu ea ho tšoaea ke HSS.

3) Cobalt e nang le tšepe e phahameng ea lebelo: hajoale e sebelisoa haholo e le lisebelisoa tsa pompo, joalo ka M35, M42, joalo-joalo, khoutu ea ho tšoaea ke HSS-E.

4) Powder metallurgy high-speed steel: E sebelisoa e le thepa ea pompo e sebetsang hantle, ts'ebetso e ntlafala haholo ha e bapisoa le tse peli tse ka holimo. Mekhoa ea ho reha mabitso ea moetsi e mong le e mong le eona e fapane, 'me khoutu ea ho tšoaea ke HSS-E-PM.

5) Lisebelisoa tsa carbide tse entsoeng ka samente: hangata li sebelisa likaroloana tse ntle haholo le limaraka tse thata, tse sebelisoang haholo ho etsa lipompo tse otlolohileng tsa lekolilo ho sebetsa lisebelisoa tse khutšoane tsa chip, joalo ka tšepe e bohlooho, silicon e phahameng ea aluminium, jj.

Lipompo li itšetlehile haholo ka thepa, 'me khetho ea thepa e ntle e ka ntlafatsa mekhoa ea lipompo, ea etsa hore e tšoanelehe bakeng sa maemo a holimo le a thata a ho sebetsa,' me ka nako e ts'oanang a be le bophelo bo phahameng ba tšebeletso. Hajoale, baetsi ba lipompo tse kholo ba na le lifeme tsa bona tsa thepa kapa liforomo tsa thepa. Ka nako e ts'oanang, ka lebaka la mathata a lisebelisoa tsa cobalt le litheko, litšepe tse ncha tsa cobalt tse sa sebetseng ka lebelo le phahameng le tsona li tsoile.

(2) Ho roala ha pompo

1) Oxidation ea mouoane: Theipi e kenngoa ka mouoane oa metsi o nang le mocheso o phahameng ho etsa filimi ea oxide holim'a metsi, e nang le adsorption e ntle ho se pholisang, e ka fokotsang khohlano, 'me ea thibela pompo le lisebelisoa ho khaoloa. E loketse ho sebetsa tšepe e bonolo.

2) Phekolo ea Nitriding: Bokaholimo ba pompo bo na le nitrided ho etsa lera le thatafalitsoeng, le loketseng machining iron cast, cast aluminium le lisebelisoa tse ling tse nang le lisebelisoa tse ntle haholo.

3) Steam + Nitriding: Kopanya melemo ea tse peli tse ka holimo.

4) TIN: seaparo sa khauta se mosehla, se nang le boima bo botle ba ho roala le mafura, le sekhomaretsi se setle sa ho roala, se loketseng ho sebetsana le lisebelisoa tse ngata.

5) TiCN: boputsoa bo boputsoa bo nang le boima bo ka bang 3000HV le ho hanyetsa mocheso oa 400 ° C.

6) TiN + TiCN: seaparo se mosehla se lefifi, se nang le boima bo botle ba ho roala le mafura, se loketseng ho sebetsana le lisebelisoa tse ngata.

7) TiAlN: ho roala botala bo botala, boima ba 3300HV, ho hanyetsa mocheso ho fihlela ho 900 ° C, ho ka sebelisoa bakeng sa machining a lebelo le phahameng.

8) CrN: ho roala silevera-grey, ts'ebetso e ntle ea ho tlotsa, e sebelisoang haholo bakeng sa ho lokisa litšepe tse se nang ferrous.

Tšusumetso ea ho roala ha pompo mabapi le ts'ebetso ea pompong e totobetse haholo, empa hona joale, bahlahisi ba bangata le bahlahisi ba ho roala ba sebelisana hammoho ho ithuta liaparo tse khethehileng.

04 Lintho tse Amang ho Tlanya

(1) Thepa ea ho tlanya

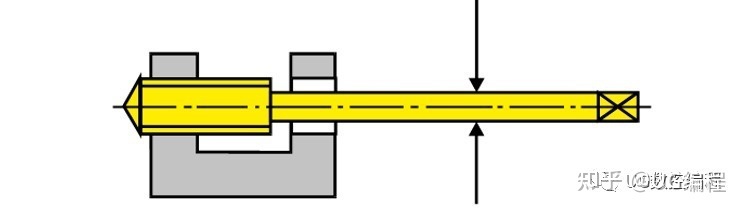

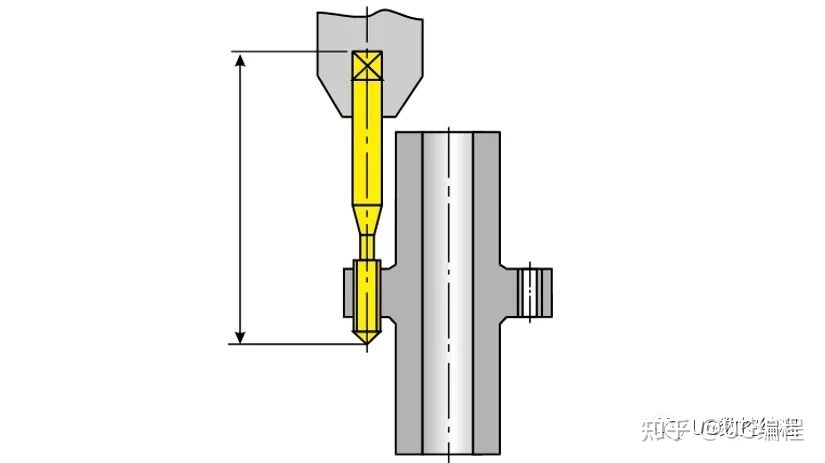

1) Sesebelisoa sa mochini: E ka aroloa ka mekhoa ea ts'ebetso e otlolohileng le e otlolohileng. Bakeng sa ho tlanya, ts'ebetso e otlolohileng e molemo ho feta ts'ebetso e otlolohileng. Ha ho pholile ka ntle ho etsoa ts'ebetsong e otlolohileng, hoa hlokahala ho nahana hore na ho pholile ho lekane.

2) Sets'oants'o sa lisebelisoa: Ho khothaletsoa ho sebelisa sesebelisoa se khethehileng sa ho tlanya bakeng sa ho tlanya. Sesebelisoa sa mochini se thata ebile se tsitsitse, 'me sets'oants'o sa sesebelisoa sa ho tapa se khethoa. Ho fapana le hoo, sets'oants'o sa sesebelisoa se tenyetsehang se nang le matšeliso a axial / radial se lokela ho sebelisoa ka hohle kamoo ho ka khonehang. . Ntle le lipompo tse nyane tsa bophara (

(2) Lisebelisoa

1) Thepa le ho thatafala ha sesebelisoa sa mosebetsi: ho thatafala ha lisebelisoa tsa mosebetsi ho lokela ho tšoana, 'me hangata ha ho khothalletsoe ho sebelisa pompo ho sebetsana le lisebelisoa tse fetang HRC42.

2) Ho tlanya sekoti se ka tlase: sebopeho sa sekoti se ka tlase, khetha sekhahla se nepahetseng sa ho phunya; ho nepahala ha boholo ba lesoba le tlase; boleng bo tlase ba lesoba la lebota.

(3) Mekhoa ea ho sebetsa

1) Lebelo la ho potoloha: Motheo oa lebelo le fanoeng la ho potoloha ke mofuta oa pompo, thepa, thepa e lokelang ho sebetsoa le ho thatafala, boleng ba lisebelisoa tsa ho penya, jj.

Hangata e khethoa ho latela litekanyo tse fanoeng ke moetsi oa pompo, lebelo le tlameha ho fokotsoa tlasa maemo a latelang:

- ho se tsitse ha mochine; phepelo e kholo ea lipompo; pholiso e sa lekaneng;

- thepa e sa lekaneng kapa boima sebakeng sa ho phunya, joalo ka manonyeletso a solder;

- pompo e lelefalitsoe, kapa ho sebelisoa molamu oa katoloso;

- Recumbent plus, pholileng ka ntle;

- Ts'ebetso ea matsoho, joalo ka ho cheka benche, ho cheka radial, joalo-joalo;

2) Fepa: ho tlanya ka thata, fepa = 1 khoele sekontiri / phetoho.

Tabeng ea ho penya habonolo le mefuta e lekaneng ea matšeliso a shank:

Fepa = (0.95-0.98) li-pitches/rev.

05 Malebela a ho khetha lipompo

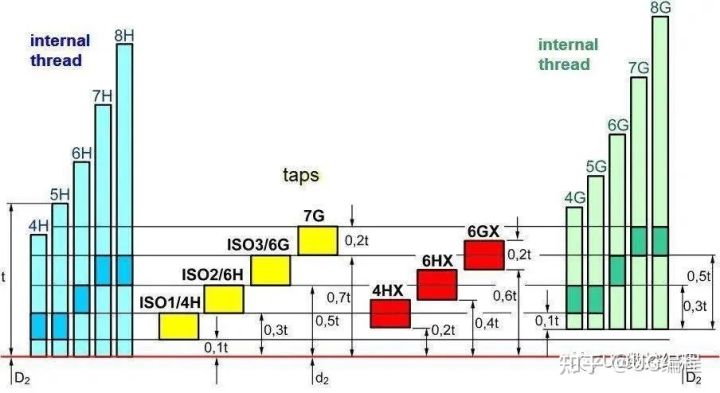

(1) Mamello ea lipompo tsa limaraka tse fapaneng tse nepahetseng

Khetho ea motheo: boemo ba ho nepahala ha pompo bo ke ke ba khethoa le ho khethoa feela ho latela boemo bo nepahetseng ba khoele e etsoang.

1) Thepa le ho thatafala ha workpiece e lokelang ho sebetsoa;

2) Lisebelisoa tsa ho tlanya (tse kang maemo a lisebelisoa tsa mochine, li-clamping holder, mehele e pholileng, joalo-joalo);

3) Ho nepahala le phoso ea tlhahiso ea pompo ka boeona.

Ka mohlala, ha u sebetsana le likhoele tsa 6H, ha u sebetsana le likarolo tsa tšepe, lipompo tse nepahetseng tsa 6H li ka sebelisoa; ha o sebetsana le tšepe e bohlooho, hobane bophara bo bohareng ba lipompo bo sebetsa ka potlako 'me katoloso ea masoba a screw e nyane, ho molemo ho sebelisa lipompo tse nepahetseng tsa 6HX. Tlanya, bophelo bo tla ba betere.

Tsebiso mabapi le ho nepahala ha lipompo tsa Majapane:

1) OSG ea pompo ea ho itšeha e sebelisa sistimi e nepahetseng ea OH, e fapaneng le maemo a ISO. Tsamaiso ea OH e nepahetseng e qobella bophara ba sehlopha sohle sa mamello ho qala ho tloha moeling o tlaase ka ho fetisisa, 'me 0.02mm e 'ngoe le e' ngoe e sebelisoa e le tekanyo e nepahetseng, e bitsoang OH1, OH2, OH3, joalo-joalo;

2) Thepa ea extrusion OSG e sebelisa sistimi e nepahetseng ea RH. Sistimi e nepahetseng ea RH e qobella bophara ba sehlopha sohle sa mamello ho qala ho tloha moeling o tlase, 'me e' ngoe le e 'ngoe ea 0.0127mm e sebelisoa e le boemo ba ho nepahala, bo bitsoang RH1, RH2, RH3, joalo-joalo.

Ka hona, ha u sebelisa lipompo tse nepahetseng tsa ISO ho nkela lipompo tse nepahetseng tsa OH sebaka, ho ke ke ha nkoa feela hore 6H e batla e lekana le kereiti ea OH3 kapa OH4. E hloka ho khethoa ka ho sokoloha, kapa ho ea ka boemo ba sebele ba moreki.

(2) Litekanyo tsa pompo

1) Tse sebelisoang haholo ke DIN, ANSI, ISO, JIS, joalo-joalo;

2) E lumelloa ho khetha bolelele bo loketseng ka kakaretso, bolelele ba lehare le boholo ba shank ho latela litlhoko tse fapaneng tsa ho sebetsana le bareki kapa maemo a teng;

3) Tšitiso nakong ea ts'ebetso;

(3) Lintlha tse 6 tsa motheo bakeng sa khetho ea lipompo

1) Mofuta oa khoele ea ho sebetsa, metric, inch, American, joalo-joalo;

2) Mofuta oa sekoti se ka tlase se khoele, ka lesoba kapa lesoba le foufetseng;

3) Thepa le ho thatafala ha workpiece e lokelang ho sebetsoa;

4) botebo ba khoele e feletseng ea workpiece le botebo ba sekoti se ka tlaase;

5) Ho nepahala ho hlokahalang ha khoele ea workpiece;

6) Boemo ba sebopeho sa pompo

Nako ea poso: Jul-20-2022