Lefatšeng la lisebelisoa tsa elektronike, liboto tsa potoloho tse hatisitsoeng (PCBs) ke mokokotlo oa hoo e batlang e le lisebelisoa tsohle tseo re li sebelisang kajeno. Ho tloha ho li-smartphone ho ea ho lisebelisoa tsa lapeng, li-PCB li bohlokoa bakeng sa ho hokahanya likarolo tse ngata tsa elektronike. E 'ngoe ea lintlha tsa bohlokoahali tsa tlhahiso ea PCB ke ts'ebetso ea ho cheka, e leng moolikotoana tsa boto ea potoloho tse hatisitsoengkena papaling. Ho blog ena, re tla hlahloba mefuta e fapaneng ea likotoana tsa ho cheka tse sebelisetsoang li-PCB, litlhaloso tsa tsona, le malebela a ho khetha sesebelisoa se nepahetseng bakeng sa projeke ea hau.

Ho utloisisa likarolo tsa PCB Drill

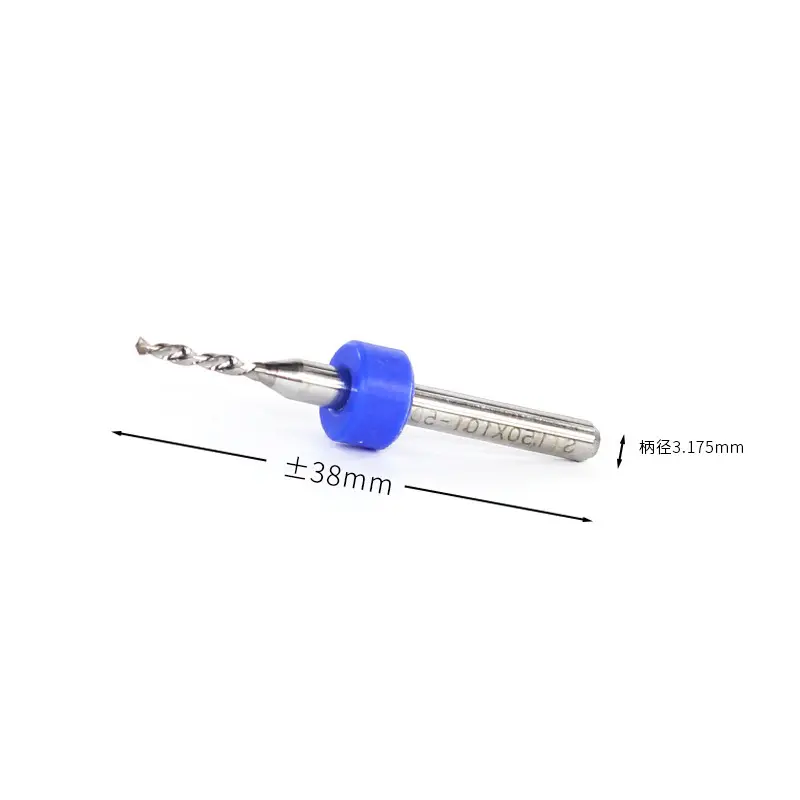

Likotoana tse hatisitsoeng tsa boto ea potoloho ke lisebelisoa tse khethehileng tse sebelisetsoang ho phunya masoba ho li-PCB ho beha likarolo le ho etsa likhokahano tsa motlakase. Likotoana tsena tsa boro li tla ka boholo le lisebelisoa tse fapaneng, e 'ngoe le e' ngoe e etselitsoe ts'ebeliso e itseng. Ho nepahala le boleng ba palo ea ho cheka ka kotloloho ho ama ts'ebetso e akaretsang le ts'epahalo ea PCB.

PCB Drill Bit Mefuta

1. Twist Drill Bit:Ona ke mofuta o atileng haholo oa ho cheka o sebelisoang bakeng sa li-PCB. Li na le sebopeho sa spiral se thusang ho tlosa litšila ha li ntse li cheka. Li-drill tsa twist li tla ka bophara bo fapaneng bakeng sa masoba a boholo bo fapaneng.

2. Micro Drill Bits:Li-Micro drill bits li bohlokoa bakeng sa lits'ebetso tse hlokang masoba a manyane haholo. Likotoana tsena tsa ho phunya li ka phunya masoba a manyane joalo ka 0.1 mm, tsa etsa hore e be tse loketseng li-PCB tse matla haholo moo sebaka se lekanyelitsoeng.

3. Lisebelisoa tsa Carbide Drill:E entsoe ka tungsten carbide, likotoana tsena tsa boro li tsebahala ka ho tšoarella ha tsona le bokhoni ba ho lula li le bohale nako e telele. Li sebetsa ka ho khetheha bakeng sa ho cheka ka thepa e thata, e leng se etsang hore e be khetho e tsebahalang bakeng sa li-PCB tse ngata.

4. Likotoana tsa ho Sebetsa ka Taemane:Bakeng sa ho qetela ka ho nepahala le ho phela nako e telele, likotoana tsa boro tse koahetsoeng ke taemane ke maemo a khauta. Sekoaelo sa daemane se fokotsa khohlano le mocheso bakeng sa ho khaola ho hloekisa le bophelo bo bolelele ba lisebelisoa. Li-drill bits hangata li sebelisoa lits'ebetsong tsa maemo a holimo moo ho nepahala ho leng bohlokoa.

Lintlha tsa bohlokoa tse lokelang ho nahanoa

Ha u khetha mochini oa ho cheka bakeng sa liboto tsa potoloho tse hatisitsoeng, ho na le lintlha tse 'maloa tseo u lokelang ho nahana ka tsona:

- Diameter:Boholo ba sekoti sa ho phunya bo bohlokoa ho netefatsa hore lesoba le kopana le litlhaloso tsa moralo oa PCB. Li-diameter tse tloaelehileng li tloha ho 0.2mm ho isa ho 3.2mm.

- Bolelele:Bolelele ba palo ea ho cheka bo lokela ho lumellana le botenya ba PCB. Liboto tse ngata li ka hloka sebaka se selelele sa ho phunya.

- Li-angles tse bohale:Li-angles tse bohale li ama bokhoni ba ho itšeha le boleng ba lesoba. Li-angles tse bohale tse tloaelehileng hangata ke likhato tse 118, empa li-angles tse khethehileng li ka sebelisoa bakeng sa lits'ebetso tse ikhethileng.

- Boitsebiso:Thepa ea "drill bit" e ama ts'ebetso ea eona le nako ea bophelo. Likotoana tsa ho cheka tsa Carbide le taemane li ratoa bakeng sa ho tšoarella ha tsona.

Litlhahiso tsa ho khetha karolo e nepahetseng ea ho phunya

1. Lekola litlhoko tsa projeke ea hau:Pele o reka sejana sa ho phunya, lekola lintlha tsa moralo oa PCB ea hau. Nahana ka boholo ba lesoba, palo ea li-layers, le lisebelisoa tse sebelisoang.

2. Boleng holim'a theko:Le hoja ho ka 'na ha e-ba tekong ea ho khetha mochini oa ho cheka o theko e tlaase, ho tsetela ka boro ea boleng bo phahameng ho ka u bolokela nako le chelete ha nako e ntse e ea. Lisebelisoa tsa pele tsa ho cheka li fokotsa kotsi ea ho robeha le ho netefatsa hore ho na le lesoba le hloekileng.

3. Leka Mefuta e fapaneng:Haeba o sa tiisehe hore na ke borona bofe bo loketseng projeke ea hau, nahana ka ho leka mefuta e 'maloa e fapaneng ea li-drill. Sena se tla u thusa ho tseba hore na ke karolo efe ea ho cheka e loketseng ts'ebeliso ea hau e khethehileng.

4. Boloka Lisebelisoa tsa Hao:Tlhokomelo e nepahetseng ea li-drill tsa hau ke ea bohlokoa ho lelefatsa bophelo ba bona. Hloekisa 'me u hlahlobe likotoana tsa ho cheka khafetsa hore na li senyehile, 'me u fetole likotoana ha ho hlokahala ho boloka tšebetso e nepahetseng.

Ha re phethela

Likotoana tse hatisitsoeng tsa boto ea potoloho ke karolo ea bohlokoa ea tlhahiso ea PCB 'me li bapala karolo ea bohlokoa ho netefatsa ho nepahala le ho ts'epahala. Ka ho utloisisa mefuta e fapaneng ea li-drill tse fumanehang le ho nahana ka lintlha tsa bohlokoa, u ka etsa qeto e nang le tsebo e tla ntlafatsa boleng ba merero ea hau ea elektroniki. Hore na o motho ea ratang ho itlosa bolutu kapa moenjineri ea hloahloa, ho tsetela ka lisebelisoa tse nepahetseng ho tla qetella ho lebisitse ho litholoana tse ntle le ts'ebetso e atlehileng haholoanyane.

Nako ea poso: Feb-20-2025