Lefatšeng le potlakileng la tlhahiso ea lisebelisoa tsa elektroniki, moo ho nepahala ha boemo ba micron ho hlalosang katleho, ho hlahisoa ha Next-Gen PCB Board Drill Bits ho tšoaea ho tlola ho hoholo ha boto ea potoloho. E etselitsoe ho cheka, ho betla le ho etsa micromachining libotong tsa potoloho tse hatisitsoeng (PCBs) le likaroloana tse ling tse tšesaane haholo, tsena tsa Tungsten Steel.Mini Drill PCBLisebelisoa li kopanya lisebelisoa tsa boemo ba sefofane le thekenoloji ea botsitso ba seismic ho hlalosa hape katleho le nako e telele tlhahisong e phahameng.

Bokhabane ba Boenjiniere: Hobaneng ha Tungsten Steel e le Bohlokoa

Bohareng ba likotoana tsena tsa ho cheka ho na le high-purity tungsten carbide (WC), thepa e khethiloeng bakeng sa motsoako oa eona o ke keng oa lekanngoa oa boima ba 'mele (HRA 92), ho hanyetsa ho apara, le botšepehi ba sebopeho. Ho fapana le liboro tse tloaelehileng tsa HSS (High-Speed Steel), mofuta ona oa tšepe oa tungsten o fana ka:

3X Nako e Telele ea Bophelo: E mamella lipotoloho tse 15,000+ tsa ho cheka libotong tsa fiberglass tsa FR-4 ntle le ho senyeha ha moeli.

Micro-Grain Structure: Sub-0.5µm ea lijo-thollo tsa carbide e netefatsa likarolo tse sehang ka lehare, ho fihlela bophara ba lesoba bo nyane joalo ka 0.1mm ka mamello ea ± 0.005mm.

Moralo oa Anti-Fracture: Shank geometry e matlafalitsoeng e thibela ho robeha nakong ea ts'ebetso ea RPM e phahameng (30,000-60,000), leha e le lisebelisoa tsa PCB tse brittle tse tlatsitsoeng ka ceramic.

Teko ea motho oa boraro ke Setsi sa Theknoloji sa Precision Machining e tiisa hore li-bits tsena li boloka Ra 0.8µm e qeta ho qeta ka mor'a masoba a 10,000 - ntlha ea bohlokoa bakeng sa botšepehi ba matšoao a phahameng ho lisebelisoa tsa 5G le IoT.

Botsitso ba Seismic: Ho Seha Ntle le ho Sekisetsa

Ho cheka ha PCB ho hloka botsitso bo felletseng ho thibela "ho tsamaea" kapa ho se tsamaisane hantle ha lesoba. Proprietary Seismic Blade Edge Design e sebetsana le sena ka:

Asymmetric Flute Geometry: E leka-lekanya ho ntšoa ha chip le ho thothomela, ho fokotsa matla a ka morao ka 40%.

Nano-Coated Helix Angle: Helix ea 30 ° e nang le seaparo sa TiAlN e fokotsa mocheso oa mocheso (<70 ° C) nakong ea ts'ebetso e tsoelang pele.

Anti-Resonance Grooves: Likanale tse emisitsoeng ka Laser li senya maqhubu a harmonic, li netefatsa ho nepahala ha maemo ka har'a 5µm ho pholletsa le 10-layer PCBs.

Tekong ea khatello ea maikutlo ea ho phunya masoba a 0.3mm ka liboto tse koahetsoeng ka aluminium tse 2mm, likotoana tsena li bonts'itse ho kheloha ho feta lipotoloho tse 500 tse latellanang - ts'ebetso e ke keng ea lekanngoa ke bahlolisani.

Likopo Hohle Liindasteri

Electronics ea bareki

Bakeng sa baetsi ba li-motherboard tsa li-smartphone:

0.2mm Micro-Vias: E fihletse litefiso tsa 99.9% tsa lihlahisoa ho liboto tse 12 tsa HDI.

20% Litefiso tsa Phepelo e Potlakileng: E nolofalitsoe ke likhohlano tse fokotsehileng le ho koaloa ha chip.

Likoloi tsa Elektronike

Ka tlhahiso ea module ea motlakase ea EV:

Ho Tšepahala ka Mokoti: E bolokile ts'ebetso ea motlakase ea 100% ho li-substrates tsa 1.6mm-thick thermal-conductive.

Ts'ebetso e sa Pholiseng: Bokhoni ba ho cheka bo omileng bo qoba tšilafalo lits'ebetsong tsa taolo ea betri e tiisitsoeng.

Sefofane le Tšireletso

Ho cheka masoba a 0.15mm ho li-circuits tsa polyimide flex:

Zero Delamination: Le maemong a 200°C a mongobo o phahameng.

EMI Shield Patterning: Ho betla ka mokhoa o nepahetseng bakeng sa likarolo tse sireletsang tsa RF tse thehiloeng ho graphene.

Litlhaloso tsa Tekheniki

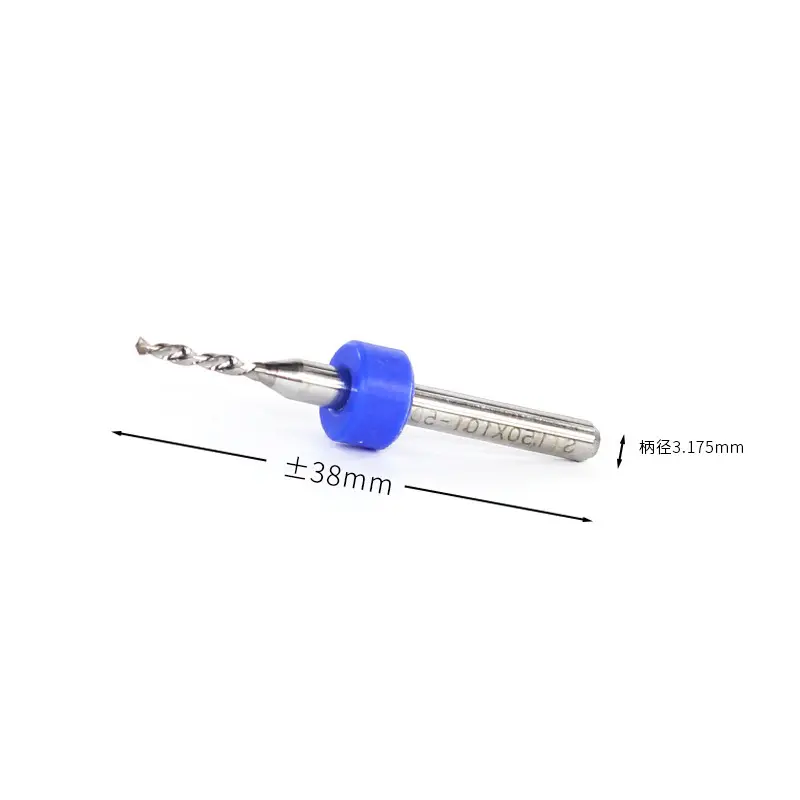

Sebaka sa bophara: 0.1mm–3.175mm (0.004"–1/8")

Mofuta oa Shank: Standard 3.175mm (1/8") kapa e tsamaellana le collet ea ER

Likhetho tsa ho roala: TiN (khauta), TiCN (putsoa), kapa Carbon-Joaloka Diamond (DLC)

Max RPM: 80,000 (ho itšetlehile ka bophara)

Tšebelisano: Mechini ea ho cheka ea CNC, mochini oa khatiso oa PCB o ikemetseng, lisebelisoa tsa rotary tse tšoaroang ka letsoho

Tšebeliso ea Litšenyehelo e Hlalositsoe bocha

Tlhahlobo ea melemo ea litšenyehelo e entsoeng ke moetsi ea ka sehloohong oa PCB oa Taiwan e senotse:

$18,500 Chelete ea Selemo le Selemo: Ho fokotsoa ha li-drill bits (ho tloha ho tse 12 ho isa ho tse 4 ka selemo).

15% Phokotso ea Matla: Litlhoko tse tlase tsa torque ea spindle.

Zero Rework: E felisitse $ 220k / selemo ka liboto tse lahliloeng ho tloha ho drill Wander.

Sustainability e hahiloeng ka hare

Sephutheloana se ka sebelisoang hape: 100% literei tsa foam tse senyehang.

RoHS & REACH Compliance: Ha e na loto, cadmium, le lintho tse ling tse kotsi.

Bophelo ba Sesebelisoa se Atolositsoeng: 60% e tlase ea tšebeliso ea tungsten khahlanong le li-drill tse tloaelehileng.

Litlhaloso tsa Basebelisi

"Ho fetohela litsing tsena tsa tšepe tsa tungsten ho bile phetoho," ho bolela Hiroshi Tanaka, Motsamaisi oa Tlhahiso ho moetsi oa sensor o thehiloeng Kyoto. "Re ntse re phunya masoba a 20,000 ka nako e le 'ngoe re sa fetole lisebelisoa - ntho e ke keng ea nahanoa ka li-drill tsa rona tsa khale tsa HSS. Moralo oa ho sisinyeha ha lefatše o le mong o fokotsa likoti tsa rona ka 95%.

Hobaneng o Khetha Li-Bits tsena tsa PCB Board Drill?

Precision e sa Senyeheng: Bakeng sa ho nepahala ho kang laser ho liboto tsa high-density interconnect (HDI).

Lebelo Ntle le Sehlabelo: Cheka masoba a 0.3mm ho likoti tse 400 / motsotso ntle le ho senya boleng ba bohale.

Tšebelisano e Akaretsang: E sebetsa le FR-4, Rogers, aluminium, esita le laminates tse matlafalitsoeng ka khalase.

Moralo oa Bopaki ba Bokamoso: E itokiselitse lisebelisoa tsa PCB tsa mofuta o latelang joalo ka li-dielectric tse se nang halogen le tse tlase haholo.

Qetello

Indastering moo micron e 'ngoe le e' ngoe e laelang phaello le ts'ebetso, tsena Tungsten SteelPCB Board Drill Bitsli ngata ho feta lisebelisoa - ke molemong oa maano. Ka ho kopanya mahlale a lintho tse bonahalang le boenjiniere ba botsitso, ba matlafatsa bahlahisi ho sutumelletsa meeli ea miniaturization ha ba ntse ba senya.

Nako ea poso: Mar-21-2025