Lisebelisoa tsa carbide tse koahetsoeng li na le melemo e latelang:

(1) Thepa ea ho roala holim'a lera e na le boima bo phahameng haholo le ho hanyetsa ho roala. Ha ho bapisoa le carbide e sa koaetsoeng e entsoeng ka samente, carbide e entsoeng ka samente e koahetsoeng e lumella tšebeliso ea lebelo le phahameng la ho itšeha, kahoo e ntlafatsa ts'ebetso ea ts'ebetso, kapa E ka eketsa haholo bophelo ba sesebelisoa ka lebelo le tšoanang la ho itšeha.

(2) Coefficient ea khohlano pakeng tsa thepa e koahetsoeng le thepa e entsoeng e nyenyane. Ha ho bapisoa le carbide e sa koaeloang e entsoeng ka samente, matla a ho itšeha a carbide e koahetsoeng e fokotsehile ho isa tekanyong e itseng, 'me boleng ba holim'a metsi bo sebetsang bo molemo.

(3) Ka lebaka la ts'ebetso e ntle e felletseng, thipa e koahetsoeng ea carbide e na le mefuta e mengata e fapaneng le mefuta e mengata ea ts'ebeliso. Mokhoa o sebelisoang ka ho fetesisa oa ho roala ka samente ea carbide ke mocheso o phahameng oa mouoane oa lik'hemik'hale (HTCVD). Plasma chemical vapor deposition (PCVD) e sebelisoa ho koahela bokaholimo ba carbide e entsoeng ka samente.

Mefuta ea ho roala ea li-cutter tse entsoeng ka samente ea carbide:

Lisebelisoa tse tharo tse tloaelehileng tsa ho roala ke titanium nitride (TiN), titanium carbonitride (TiCN) le titanium aluminide (TiAIN).

Ho roala ha "titanium nitride" ho ka eketsa ho thatafala le ho roala ho hanyetsa ha sesebelisoa, ho fokotsa coefficient ea likhohlano, ho fokotsa tlhahiso ea bohale bo hahiloeng, le ho lelefatsa bophelo ba sesebelisoa. Lisebelisoa tse koahetsoeng ka titanium nitride li loketse ho sebetsana le tšepe e tlaase ea alloy le tšepe e sa hloekang.

Bokaholimo ba lesela la titanium carbonitride bo bohlooho, boima bo phahame ho feta ba titanium nitride coating, 'me ho hanyetsa ho apara ho molemo. Ha ho bapisoa le ho roala ha titanium nitride, sesebelisoa sa ho roala sa titanium carbonitride se ka sebetsoa ka lebelo le leholo la fepa le lebelo la ho itšeha (40% le 60% e phahameng ho feta ea titanium nitride bar, ka ho latellana), 'me sekhahla sa ho tlosoa ha thepa ea workpiece se phahame. Lisebelisoa tse koahetsoeng ka Titanium carbonitride li ka sebetsana le lisebelisoa tse fapaneng tsa mosebetsi.

Thepa ea titanium aluminide e bohlooho kapa e ntšo. Haholo-holo e koahetsoe ka holim'a setsi sa sesebelisoa sa carbide se entsoeng ka samente. E ntse e ka sebetsoa ha mocheso oa ho itšeha o fihla ho 800 ℃. E loketse ho itšeha ka lebelo le phahameng. Nakong ea ho khaola ho omileng, li-chips sebakeng sa ho itšeha li ka tlosoa ka moea o hatelitsoeng. Titanium aluminide e loketse ho sebetsana le lisebelisoa tse brittle joalo ka tšepe e thata, alloy ea titanium, alloy e thehiloeng ho nickel, tšepe e entsoeng ka tšepe le alloy e phahameng ea silicon.

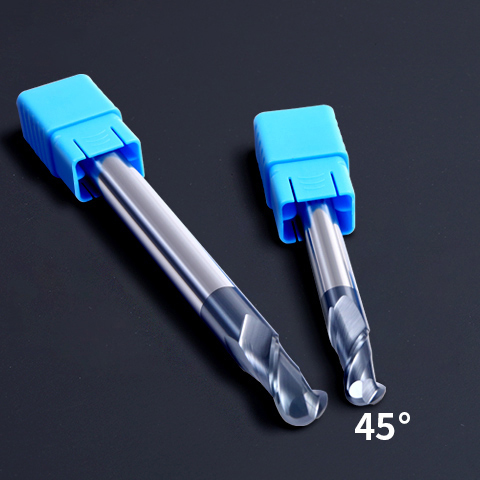

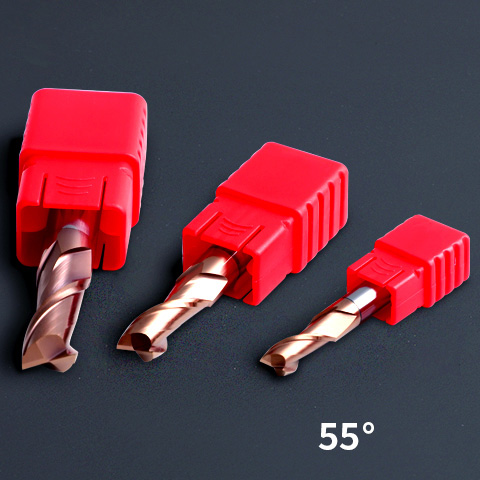

Tšebeliso ea ho roala ea seha sekontiri se entsoeng ka carbide:

Tsoelo-pele ea theknoloji ea ho roala lisebelisoa e boetse e bonahala ka ts'ebetso ea nano-coating. Ho roala lisebelisoa tse makholo tse nang le botenya ba li-nanometer tse 'maloa holim'a lisebelisoa tsa motheo tsa lisebelisoa ho bitsoa nano-coating. Boholo ba karolo e 'ngoe le e' ngoe ea thepa ea ho roala ka nano e nyenyane haholo, kahoo moeli oa lijo-thollo o telele haholo, o nang le boima bo phahameng ba mocheso o phahameng. , Matla le fracture toughness.

Boima ba Vickers ba nano-coating bo ka fihla HV2800 ~ 3000, 'me ho hanyetsa ho apara ho ntlafatsoa ka 5% ~ 50% ho feta ea thepa ea micron. Ho latela litlaleho, hajoale, ho entsoe likarolo tse 62 tsa lisebelisoa tsa ho roala tse nang le liphaephe tse fapaneng tsa titanium carbide le titanium carbonitride le likarolo tse 400 tsa lisebelisoa tsa nano-coated tsa TiAlN-TiAlN/Al2O3.

Ha ho bapisoa le liphahlo tse thata tse ka holimo, sulfide (MoS2, WS2) e koahetsoeng ka tšepe e lebelo le phahameng e bitsoa "soft coating", e sebelisoang haholo-holo bakeng sa ho seha lisebelisoa tsa aluminium tse matla haholo, li-alloys tsa titanium le lisebelisoa tse ling tse sa tloaelehang.

Haeba u na le tlhoko, ka kopo ikopanye le MSK, re ikemiselitse ho fana ka lisebelisoa tsa boholo bo tloaelehileng ka nako e khuts'oane le moralo oa lisebelisoa tse etselitsoeng bareki.

Nako ea poso: Sep-22-2021