Ho khanna ho sa khaotseng ho lebisa likoloing tse bobebe, tse matla, le tse sebetsang hantle, haholo-holo ka kholo e phatlohang ea Likoloi tsa Motlakase (EVs), e beha khatello e kholo tlhahisong ea likoloi. Mekhoa ea setso ea ho theha likhokahano tse matla ka tšepe e tšesaane - e leng setsi sa 'mele ea sejoale-joale ea likoloi, liforeimi le liphaello - hangata li kenyelletsa li-fasteners tse kang linate tsa weld kapa linate tsa rivet. Tsena li hlahisa ho rarahana, boima, lintlha tse ka bang teng tsa ho hloleha, le linako tse liehang tsa potoloho. Kenya Thermal Friction Drilling (TFD) le lisebelisoa tsa eona tse khethehileng -Carbide Flow Drill Bits le Thermal Friction Drill Bit Sets - thekenoloji e fetolang mela ea tlhahiso ea likoloi ka potlako ka ho iketsetsa ho thehoa ha likhoele tsa bohlokoa, tse matla ka ho toba ka har'a lisebelisoa tse tšesaane.

Bothata ba ho Itima Likoloi: Boima, Matla, Lebelo

Baenjiniere ba likoloi ba lula ba loana le bothata ba ho matlafatsa boima ba 'mele. Litšepe tse tšesaane, tse matla a phahameng le lialloys tsa aluminium li bohlokoa bakeng sa ho fokotsa boima ba koloi le ho ntlafatsa ts'ebetso ea mafura kapa mefuta ea EV. Leha ho le joalo, ho theha likhoele tse ka tšeptjoang tse jarang moroalo likarolong tsena tse tšesaane ho na le bothata:

Ho Kopanelana ho Lekanyelitsoeng: Ho tlanya ka tloaelo pampiring e tšesaane ho fana ka khoele e fokolang, e lebisang ho matla a tlase a ho hula le ho ba le monyetla oa ho hlobola.

Mathata a Eketsehileng le Boima ba 'Mele: Li-weld nuts, clinch nuts, kapa rivet nuts li eketsa likarolo, li hloka ts'ebetso ea bobeli (ho cheselletsa, ho hatella), ho eketsa boima ba' mele, le ho hlahisa liwebsaete tse ka senyehang kapa mathata a ho laola boleng.

Li-bottlenecks tsa Ts'ebetso: Ho cheka ho arohaneng, ho kenya li-fasteners / ho kenya letsoho, le mehato ea ho tlanya e liehisa mela ea tlhahiso e phahameng.

Mocheso le Khopamiso: Linate tse chesellang li hlahisa mocheso o moholo, o ka bang o sotha liphanele tse tšesaane kapa tse amang thepa sebakeng sa Heat Affected Zone (HAZ).

Phallo Drills: The Automated Solution on the Line

Thermal Friction Drilling, e kenyellelitsoeng litsing tsa machining tsa CNC, lisele tsa liroboto, kapa metjhini e inehetseng ea li-spindle tse ngata, e fana ka karabo e matla:

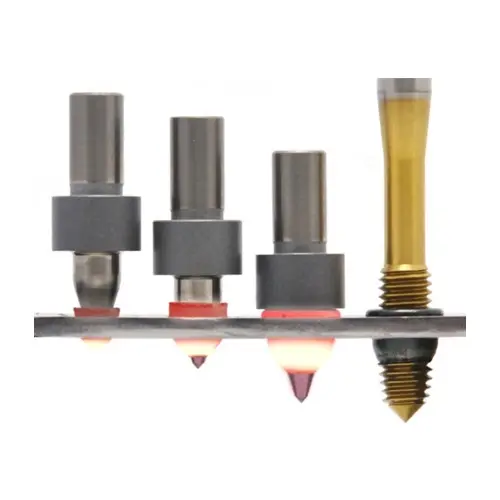

Single Operation Powerhouse: Boloi ba mantlha ba TFD bo ka har'a ho kopanya ho cheka, ho etsa lihlahla, le ho kenella ts'ebetsong e le 'ngoe e se nang moeli, e ikemetseng. Carbide Flow Drill Bit e le 'ngoe, e potolohang ka lebelo le phahameng (ka tloaelo 3000-6000 RPM bakeng sa tšepe, e phahameng bakeng sa aluminium) tlas'a matla a bohlokoa a axial, e hlahisa mocheso o matla oa likhohlano. Sena se etsa hore tšepe e be polasetiki, e lumellang geometry e ikhethang ea karoloana hore e phalle le ho tlosa thepa sebakeng sa eona, e etsa sehlahla se se nang sekoli, se kopanyang hoo e ka bang makhetlo a 3 ho feta botenya ba lakane ea mantlha.

Ho Tlanya Hang-hang: Ha Flow Drill e hula ka morao, pompo e tloaelehileng (hangata e holim'a sesebelisoa se le seng ka har'a sistimi ea phapanyetsano ea boiketsetso kapa spindle ea bobeli e hokahantsoeng) hang-hang ea latela, e seha likhoele tse nepahetseng haholo ho sehlahla sena se sa tsoa thehoa, se nang le marako a teteaneng. Sena se felisa ho sebetsana pakeng tsa ts'ebetso le ho fokotsa haholo nako ea potoloho.

Khokahano ea Robotic: Thermal Friction Drill Bit Sets e loketse hantle matsoho a roboto. Bokhoni ba bona ba ho etsa ts'ebetso eohle ea ho theha likhoele ka tsela e le 'ngoe ea sesebelisoa (ho phunya, ho etsa bushing, ho hula, ho theola, ho hulanya) ho nolofatsa mananeo le ts'ebetso ea liroboto. Liroboto li ka beha sesebelisoa hantle holim'a li-contours tse rarahaneng holim'a sebopeho sa body-in-white (BIW) kapa likopanong tse nyane.

Hobaneng ha Baetsi ba Likoloi ba Amohela Mechini ea Phallo:

Matla a Eketsehileng a Khoele: Ona ke monyetla o ka sehloohong. Likhoele li kopanya lihlahla tse teteaneng (mohlala, ho theha sehlahla se bolelele ba 9mm ho tloha ka lakane ea 3mm), se hlahisang matla a ho hula le ho hlobola hangata a fetang a linate tsa weld kapa rivet nut. Sena ke sa bohlokoa bakeng sa likarolo tsa bohlokoa tsa polokeho (liankora tsa mabanta a setulo, lithapo tse emisitsoeng) le libaka tse thothomelang haholo.

Phokotso e Bohlokoa ea Boima: Ho felisa nate ea weld, rivet nut, kapa clinch nut ka boeona ho tlosa boima ba 'mele. Habohlokoa le ho feta, hangata e lumella baqapi hore ba sebelise lisebelisoa tsa gauge tse tšesaane ka kakaretso ho tloha ha bushing e entsoeng e fana ka matlafatso ea lehae moo ho hlokahalang matla, ntle le ho eketsa boima libakeng tse ling. Ligrama tse bolokiloeng ka khokahanyo e ngoe le e ngoe li ikatisa ka potlako ho pholletsa le koloi.

Ts'ebetso e sa Bapisoeng le Lebelo: Ho kopanya ts'ebetso e meraro ka linako tse le 'ngoe tsa potoloho ea li-slash. Mocheso o tloaelehileng oa ho cheka le ho penya o ka phethoa ka metsotsoana e 2-6, ka potlako haholo ho feta ho cheka ka tatellano, ho beha linate / welding, le ho tlanya. Sena se eketsa ts'ebetso ho mela ea molumo o phahameng.

Boleng bo Ntlafetseng le ho Tiisa: TFD e Ikemetseng e fana ka botsitso bo ikhethang ba lesoba ho ea ho sekoti. Ts'ebetso ena e phetoa haholo tlas'a CNC e laoloang kapa li-parameter tsa robotiki, ho fokotsa phoso ea motho e tloaelehileng ho beoa ha linate kapa ho cheselletsa. Sehlahla se entsoeng se etsa hore ho be le lesoba le boreleli, hangata le koetsoeng, ho ntlafatsa ho hanyetsa ha kutu le ho khomarela pente.

Ho Fokotsa Mathata a Sisteme le Litšenyehelo: Ho felisa li-feeding tsa linate tse arohaneng, liteishene tsa welding, li-weld controller, le licheke tsa boleng tse amanang le tsona ho fokotsa litšenyehelo tsa thepa ea thepa, litlhoko tsa sebaka sa fatše, ho rarahana ha tlhokomelo, le lintho tse ka sebelisoang (ha ho na terata / khase ea welding, ha ho na linate).

Ntlafatso ea Botšepehi bo Kopanetsoeng: The integral bushing e etsa karolo ea metallurgical e tsoelang pele ea thepa ea motheo. Ha ho na kotsi ea hore nate e theohe, e ohiloe, kapa e theohe joalo ka litšepe tsa mochini, 'me ha ho na mathata a HAZ a bapisoang le welding.

Material Versatility: Carbide Flow Drill Bits e sebetsana ka katleho le lisebelisoa tse fapaneng tsa likoloi tsa sejoale-joale: tšepe e bonolo, tšepe ea High-Strength Low-Alloy (HSLA), Advanced High-Strength Steel (AHSS), lisebelisoa tsa aluminium (5xxx, 6xxx), esita le likarolo tse ling tse se nang tšepe. Liaparo tsa lisebelisoa (joalo ka AlCrN bakeng sa aluminium, TiAlN bakeng sa tšepe) li ntlafatsa ts'ebetso le bophelo.

Kamohelo ea Lits'ebetso tsa Konokono tsa Koloi:

EV Battery Enclosures & Trays: Mohlomong ke mokhanni a le mong e moholo. Mehaho ena e meholo, e nang le marako a tšesaane (hangata ke aluminiamo) e hloka lintlha tse ngata tsa matla a phahameng, tse nang le bopaki ba ho lutla bakeng sa ho hlongoa, likoahelo, lipoleiti tse pholileng le lisebelisoa tsa motlakase. TFD e fana ka matla a hlokahalang ntle le ho eketsa boima kapa ho rarahana. Sehlahla se tiisitsoeng se thusa ho thibela ho kenella ha pholileng.

Chassis & Subframes: Li-brackets, crossmembers, le lintlha tse fanyehiloeng li rua molemo ho matla a TFD le ho hanyetsa ho sisinyeha ka litšepe tse tšesaane, tse matla haholo.

Liforeimi le Mekhoa ea Litulo: Likarolo tsa bohlokoa tsa polokeho tse hlokang matla a phahameng haholo a ho hula bakeng sa liankora tsa mabanta le libaka tse holisang tse tiileng. TFD e felisa li-fasteners tse ngata le ho sotha ha welding.

Body-in-White (BIW): Li-brackets tse fapaneng, li-reinforcement le libaka tse holisang kahare kahare ho sebopeho sa koloi moo linate tse kentsoeng li leng boima le ho chesehela ho sa ratehe.

Exhaust Systems: Ho beha lihanger le lihokelo tsa thebe ea mocheso holim'a tšepe e tšesaane e sa hloekang kapa tšepe ea aluminiized e rua molemo ho tsoa ho lesoba le koetsoeng le sa bolaeeng le ho hanyetsa ho thothomela.

HVAC Units & Ducting: Libaka tse hloahloa le liphanele tsa phihlello ea lits'ebeletso tse hlokang likhoele tse tiileng ka har'a likoti tse tšesaane tsa tšepe.

Bohlokoa ba Carbide ho TFD ea Likoloi:

Likarolo tsa tlhahiso ea likoloi li telele, li hloka ts'epo ea lisebelisoa le bophelo bo bolelele. Li-Carbide Flow Drill Bits ha li ka buisanoa. Li mamella mocheso o feteletseng oa likhohlano (hangata o fetang 800 ° C/1472 ° F ntlheng), lebelo le phahameng la ho potoloha, le matla a bohlokoa a axial a kopana le makhetlo a likete-kete nako le nako. Li-substrates tse tsoetseng pele tsa li-micro-grain carbide le liphahlo tse khethehileng (TiAlN, AlTiN, AlCrN) li etselitsoe lisebelisoa tse khethehileng tsa likoloi, ho ntlafatsa bophelo ba lisebelisoa le ho boloka sebopeho se tsitsitseng le boleng ba masoba bo bohlokoa bakeng sa mekhoa ea boiketsetso. E hlokometsoeng hantleThermal Friction Drill Bit Bit Sete ka sebetsana le likoti tse likete pele e hloka ho nkeloa sebaka, e fana ka moruo o motle ka ho fetisisa.

Kopanyo le Bokamoso:

Khokahano e atlehileng e kenyelletsa taolo e nepahetseng ea RPM, litefiso tsa phepelo, matla a axial, le ho pholisa (hangata ho phatloha ho fokolang ha moea ho fapana le ho pholisa likhohola ho qoba ho tima sehlahla). Sistimi ea ho beha leihlo e lekola moaparo oa lisebelisoa le mekhoa ea ts'ebetso bakeng sa tokiso e boletsoeng esale pele. Ha moralo oa likoloi o ntse o hatela pele ho ea meahong ea lisebelisoa tse ngata (mohlala, 'mele oa aluminium holim'a liforeimi tsa tšepe) le mabone a maholo le ho feta, tlhoko ea theknoloji ea Flow Drill e tla mpefala. Bokhoni ba eona ba ho theha likhoele tsa lehae, tse matla haholo ka lisebelisoa tse tšesaane, tse fapaneng, ka kotloloho ka har'a phallo ea tlhahiso ea boiketsetso, maemo a Thermal Friction Drilling eseng joalo ka mokhoa o mong, empa e le tekanyetso ea nako e tlang bakeng sa ho tiisa likoloi tse matla, tse matla haholo. Ke phetoho ea ho theha likoloi tse matla, tse bobebe ka nako e le 'ngoe.

Nako ea poso: Aug-21-2025