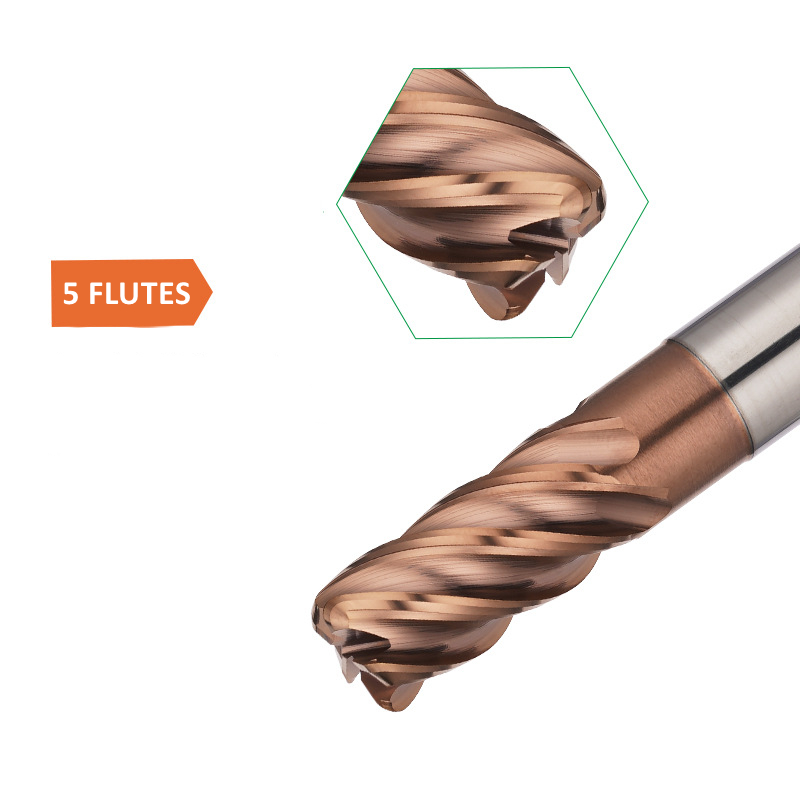

Poone Radius Mill Bakeng sa Nickel-Thehiloeng High-Temp Alloys

TLHALOSO EA SEHLAHISOA

Titanium ke ntho e tsebahalang e thata haholo ho e etsa mochini, haholo-holo litseleng tse mabifi, joalo ka tse amanang le High Efficiency Milling (HEM). Sekhahla sena sa "radius milling cutter" se sebelisoa ka ho khetheha bakeng sa ho lokisa lisebelisoa tsa indasteri ea lifofane. E amohela thepa ea tšepe ea tungsten e tsoang kantle ho naha mme e na le bophelo bo bolelele ba ts'ebeletso.

KHOTHATSO EA HO SEBELISA LITHUPANG

Titanium alloy TC18-21, ferrite, high-nickel alloy ka holimo ho 35%, tšepe e sa hloekang ea mocheso o phahameng, nickel-chromium-cobalt le lisebelisoa tse ling tse thata ho khaola titanium e matla, lisebelisoa tse nang le mocheso o phahameng oa mocheso.

Moralo oa 5-flute o potlakile ka 30% -40% ho feta sehahi sa 3-flute/4-flute

Sebopeho sa Seismic / Ultra High Metal Removal Rate / Low Internal Stress

| Flute Diameter | D6-D12 | Bolelele ba Flute | 8-24 limilimithara |

| Mofuta oa Flute | Helical | Lintho tse bonahalang | Tungsten ea boleng bo holimo |

| Ho roala | Ee | Brand | MSK |

| Tshebetso Range | Lisebelisoa tse thata tsa ho seha tse kang li-alloys tsa titanium, li-superalloys, li-ferrites, 'mele ea nickel, litšepe tse nang le mocheso o phahameng oa mocheso, le nickel-chromium-cobalt. | ||

| Mechini e sebetsang | Mechini e silang, litsi tsa machining tsa CNC, li-gong tsa likhomphutha, metjhini e betlang | ||

TŠEBELETSO

1.Special bakeng sa lisebelisoa tsa Titanium /superalloy tse thata ho khaola

E na le "lubricating" e phahameng le coefficient coefficient coefficient coefficient, e leng ho fokotsa khatello ea ka hare ea thepa.

2.Geometry Flute

Moralo o motle oa 5-blade U-groove geometric e ka eketsa sebaka sa ho ikopanya le thepa e lokelang ho sebetsoa, ha e ntse e eketsa ho tiea ha sesebelisoa le ho netefatsa bokhabane bo holimo.

3.Bara ea tšepe ea tungsten e tsoang kantle

Ho nepahala ha Shank tolerance ea H5, e etselitsoeng ka ho khetheha lits'ebetso tse phahameng tse nepahetseng tsa shank clamping.

4.Moqapi oa Chamfer

Etsa hore ho be bonolo ho tlamelloa.

Moqapi oa 5.Seismic

Sekhahla se phahameng sa ho tlosa tšepe, khatello e tlase ea kahare, 30% -40% ka potlako ho feta li-gritter tsa setso tsa 3-blade / 4-blade.

Kopo:

Aerospace, sesole, likarolo tsa mochini, likoloi, puisano e khethehileng ea elektronike le likarolo tse ling

Temoso ea Moreki:

1. Pele o sebelisa sesebelisoa, ka kopo lekanya ho kheloha ha sesebelisoa. Ha ho nepahala ha sesebelisoa ho feta 0.01mm, ka kopo e lokise pele u seha.

2. Ha e le khuts'oane bolelele ba sesebelisoa se khomarelang ka ntle ho chuck, ho molemo. Haeba sesebelisoa se tšoarella nako e telele, lebelo, sekhahla sa phepelo le palo ea ho itšeha li hloka ho fokotsoa.

3. Nakong ea ho itšeha, haeba ho thothomela ho sa tloaelehang kapa molumo, ka kopo fokotsa lebelo le ho itšeha ho fihlela boemo bo ntlafala.

4. Ho pholile ka tšepe ho molemo ka ho fetisisa ho fafatsa le sefofane sa moea, se ka ntlafatsang phello ea tšebeliso ea sehahi sa milling. Li-alloys tsa Titanium le li-superalloys tse ling ha li khothalletsoe.