Boleng bo Phahameng Import M35 Thread Forming Tap For Milling Machine

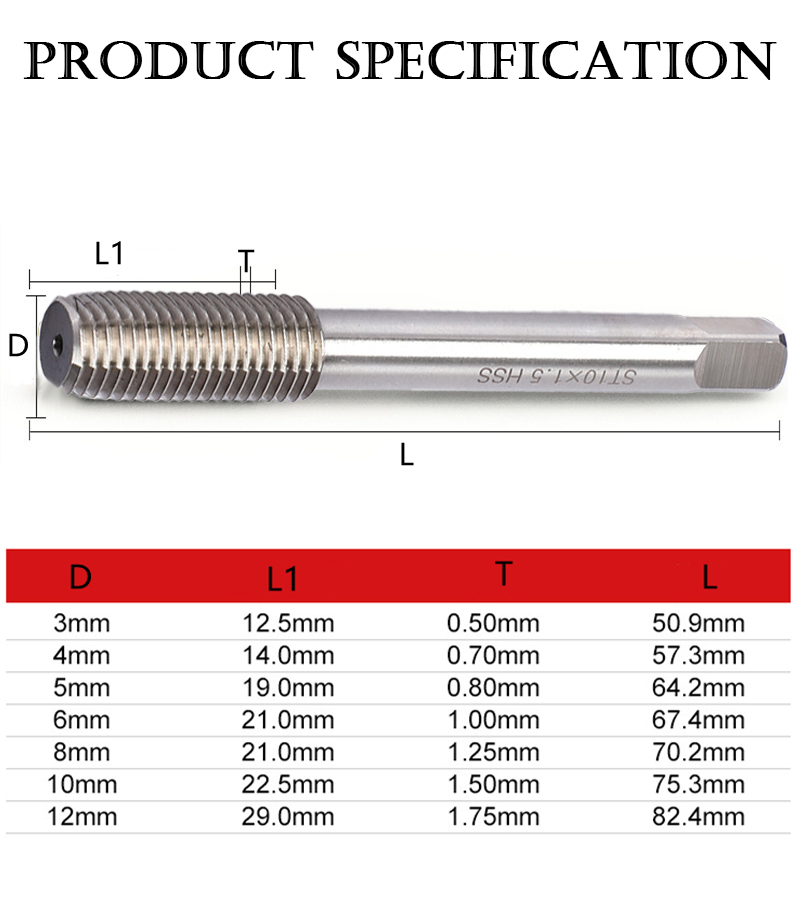

TLHALOSO EA SEHLAHISOA

| Brand | MSK | Ho roala | TiN |

| MOQ | 3 li-PC | Sebelisa thepa | Lisebelisoa tsa CNC, mochini oa ho cheka o nepahetseng |

| Lintho tse bonahalang | Ho lata M35 | Mofuta oa Motšoantšisi | Maemo a Sejapane |

MOLEMO

Sehlooho: Ho Ntlafatsa Bokhoni le ho Nepaha ka Thepa ea Ho Etsa Likhoele

tsebisa:

Tlhahisong ea kajeno e potlakileng, ts'ebetso le ho nepahala li bohlokoa haholo. Thepa e etsang khoele ke sesebelisoa se fetotseng mokhoa oa ho roala thepa. Sesebelisoa sena sa boqapi se eketsa haholo ts'epahalo le ho tšoarella ha likhokahano tsa likhoele ha li bapisoa le mekhoa ea setso. Ho blog ena, re tla hlahloba melemo ea ho sebelisa lipompo tse etsang likhoele le hore na li ka thusa joang ho nolofatsa ts'ebetso ea tlhahiso.

1. Utloisisa tšebetso:

Lipompo tsa ho etsa likhoele ke lisebelisoa tsa bohlokoa tse nepahetseng indastering ea mochini. Ho fapana le lipompo tsa setso tse sehang likhoele, lipompo tse etsang likhoele li sebetsa ka ho hlophisa lintho bocha ho hlahisa likhoele ka nepo le botsitso bo ikhethang. Ka ho sebelisa khatello e laoloang, pompo e tsamaisa lintho ntle le ho baka khatello ea maikutlo. Ts'ebetso ena ea deformation ha e matlafatse khoele feela, empa hape e fokotsa kotsi ea mapetsong kapa lintlha tse fokolang tsa thepa. Ka lebaka leo, likhoebo li ka itšetleha ka ho tiea le ho phela nako e telele ha likhokahano tse nang le likhoele.

2. Melemo ea bohlokoa:

Ho sebelisa pompo ea ho etsa likhoele ho na le melemo e mengata e etsang hore e be khetho ea pele lits'ebetsong tse ngata. Ntle le ho eketsa matla le ho tšoarella ha likhoele, lipompo tsena li fokotsa kotsi ea ho hlobola kapa ho senyeha ha thepa. Likhoele tse hlahisoang li na le khanyetso e ntle ea ho thothomela le ho lokoloha, ho etsa hore li tšepahale haholoanyane likopanong tse mahlonoko. Ho phaella moo, ka lebaka la ts'ebetso e sebetsang ea deformation, basebetsi ba ka finyella tlhahiso e phahameng ha ba ntse ba fokotsa sekhechana le ho sebetsa hape. Lipompo tse etsang likhoele le tsona ke khetho e ntle ho tikoloho hobane li hloka matla a fokolang mme li hlahisa li-chips tse fokolang ho feta mekhoa ea khale ea ho tlanya.

3. Lisebelisoa tse loketseng:

Lipompo tse etsang likhoele li sebelisoa liindastering tse fapaneng tse kenyeletsang tsa likoloi, tsa sefofane, tsa lipeipi le tsa elektroniki. Bokhoni ba bona ba ho etsa likhoele ka thepa e fapaneng, ho kenyeletsoa litšepe, lipolasetiki le li-composite, li kenya letsoho ho feto-fetoheng ha tsona. Hore na ho etsa likhoele ka li-block tsa enjine ea aluminium, li-fittings tsa tšepe e sa hloekang, kapa likarolo tsa polasetiki, lipompo tse etsang likhoele li fana ka liphetho tse ts'oanang. Ho lumellana ha tsona le mefuta e fapaneng ea lisebelisoa ho netefatsa hore bahlahisi ba ka ntlafatsa lits'ebetso tsa bona ntle le ho sekisetsa ho nepahala kapa ho itela.

4. Mekhoa e metle bakeng sa liphetho tse ntle:

Ho eketsa melemo ea lipompo tsa ho etsa likhoele, mekhoa e metle ea indasteri e tlameha ho lateloa. Taba ea pele, ho bohlokoa ho khetha geometry ea pompo e nepahetseng bakeng sa thepa ea khoele. Sena se netefatsa deformation e nepahetseng ntle le matla a feteletseng, ho fokotsa kotsi ea ho senya lisebelisoa kapa likhoele tse sothehileng. Ho tlotsa ka mokhoa o nepahetseng nakong ea ho tlanya le hona ho phetha karolo ea bohlokoa ho fumaneng litholoana tse ntle. Ho feta moo, ho fana ka botsitso bo lekaneng ba mochini le ho boloka lebelo le nepahetseng la ho itšeha ho tla thusa ho eketsa bophelo ba pompo le katleho e akaretsang ea ho roala.

ha re phethela:

Lipompo tse etsang likhoele li fetotse papali tlhahisong, ho fetola sebopeho sa likhoele ka thepa. Bokhoni ba bona ba ho fana ka likhoele tse matla, tse tšepahalang le tse nepahetseng ha li ntse li eketseha ka katleho li ba etsa sesebelisoa se matla lits'ebetsong tse ngata. Tšebeliso ea likhoele tse etsang likhoele ha e ntlafatse feela boleng ba likhokahano tse lohiloeng, empa hape e eketsa tlhahiso e akaretsang ea ts'ebetso ea machining. Ka ho sebelisa theknoloji ena e ncha, bahlahisi ba ka boloka boemo bo etelletseng pele 'marakeng o nang le tlholisano e phahameng, ha ba ntse ba kopana le litekanyetso tse tiileng tsa boleng le ho netefatsa ho tšoarella ha likaroloana tse lohiloeng.