Boleng bo Botle ba HRC 55 Solid Carbide Reamer bakeng sa Mochini oa CNC

Re hlahisa sehahi sa rona se sehang ka thata sa hinge, se ithorisang ka boima bo makatsang ba HRC55. Sesebelisoa sena se entsoe ka boqhetseke ho fana ka ts'ebetso e ikhethang le ho nepahala lits'ebetsong tse fapaneng. Lintlha tsa HRC55 li netefatsa hore lehare le boloka bohale ba lona ha le sebelisoa nako e telele, le netefatsa ts'ebetso e tsitsitseng le e tšepahalang. Hore na o sebetsa mererong e rarahaneng ea ho betla mapolanka kapa o batla lisebelisoa tsa tšepe tse ngata, hinge cutter ena e etselitsoe ho fihlela maemo a holimo, e etsa hore e be sesebelisoa sa bohlokoa bakeng sa litsebi tsa mesebetsi ea matsoho le litsebi ka ho tšoana. Tsetela ka nepo le bophelo bo bolelele ka HRC55 hard alloy hinge cutter.

| Bophara ba lekolilo(d) | Bolelele ba lekolilo(L) | Bolelele kaofela(L) | Shank bophara(D) | Palo ea phala(F) |

| 1 | 15 | 50 | 1 | 4 |

| 1.5 | 15 | 50 | 1.5 | 4 |

| 2 | 15 | 50 | 2 | 4 |

| 2.5 | 15 | 50 | 2.5 | 4 |

| 3 | 20 | 50 | 3 | 4 |

| 3.5 | 20 | 50 | 3.5 | 4 |

| 4 | 20 | 50 | 4 | 4 |

| 4.5 | 22 | 50 | 4.5 | 4 |

| 5 | 22 | 60 | 5 | 4 |

| 5.5 | 25 | 60 | 5.5 | 4 |

| 6 | 25 | 60 | 6 | 6 |

| 7 | 28 | 69 | 7 | 6 |

| 8 | 28 | 70 | 8 | 6 |

| 9 | 32 | 80 | 9 | 6 |

| 10 | 32 | 80 | 10 | 6 |

| 11 | 35 | 80 | 11 | 6 |

| 12 | 35 | 80 | 12 | 6 |

| 13 | 50 | 100 | 13 | 6 |

| 14 | 50 | 100 | 14 | 6 |

| 15 | 50 | 100 | 15 | 6 |

| 16 | 50 | 100 | 16 | 6 |

| 18 | 50 | 100 | 18 | 6 |

| 20 | 50 | 100 | 20 | 6 |

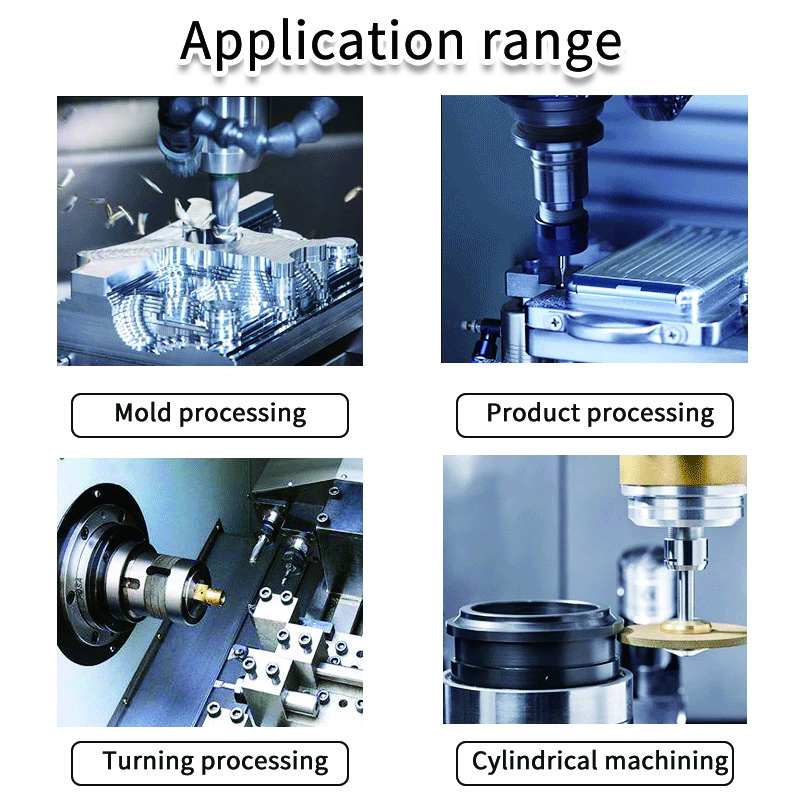

Reamer ke sesebelisoa se feto-fetohang se sebelisoang haholo ho sebetsa ka tšepe bakeng sa ho seha le ho etsa mefuta e fapaneng ea lisebelisoa tsa tšepe. Sesebelisoa se na le lehare le tiileng le mofeng o etsang maqeba a nepahetseng holim'a tšepe ka ho khutlisetsa lehare ka letsoho kapa ka mochini.

Sesebelisoa sena se bapala karolo ea bohlokoa liindastering tse fapaneng tse kang tlhahiso, kaho le tlhokomelo. Mefuta e mengata ea ts'ebeliso ea eona e etsa hore e be letlotlo la bohlokoahali ts'ebetsong ea ts'ebetso ea tšepe, e fanang ka ts'ehetso ea bohlokoa bakeng sa mesebetsi e hlokang ho nepahala, ho sebetsa hantle le ho feto-fetoha ha maemo.

| Brand | MSK | Ho paka | Lebokose la polasetiki kapa tse ling |

| Lintho tse bonahalang | 20CrMnTi | Tšebeliso | Cnc Milling Machine Lathe |

| Tšehetso e hlophisitsoeng | OEM, ODM | Mofuta | NBT-ER |

Seo bareki ba se buang ka rona

LBH

Q1: Re bo-mang?

A1: MSK (Tianjin) Cutting Technology Co., Ltd. e thehiloe ka 2015. E ntse e hōla 'me e fetile Rheinland ISO 9001.

Ka lisebelisoa tsa machaba tse tsoetseng pele tsa tlhahiso tse kang SACCKE setsi sa ho sila se nang le li-axis tse hlano Jeremane, setsi sa tlhahlobo ea lisebelisoa tsa lisebelisoa tse tšeletseng tsa ZOLLER Jeremane, le lisebelisoa tsa mochine oa PALMARY Taiwan, e ikemiselitse ho hlahisa lisebelisoa tsa CNC tse phahameng, tsa setsebi, tse sebetsang hantle le tse tšoarellang.

Q2: Na u khoebo ea k'hamphani kapa moetsi?

A2: Re moetsi oa lisebelisoa tsa carbide.

Q3: Na o ka romella sehlahisoa ho morekisi oa rona oa China?

A3: E, haeba u na le mofani oa thepa Chaena, re thabela ho romela lihlahisoa ho eena.

Q4: Ke lipehelo life tsa tefo tse ka amoheloang?

A4: Hangata re amohela T/T.

Q5: Na u amohela litaelo tsa OEM?

A5: E, OEM le customization lia fumaneha, re boetse re fana ka tšebeletso ea khatiso ea label ea tloaelo.

Q6: Ke hobane'ng ha u re khetha?

1) Taolo ea litšenyehelo - reka lihlahisoa tsa boleng bo holimo ka theko e nepahetseng.

2) Karabelo e potlakileng - nakong ea lihora tse 48, litsebi li tla u fa mantsoe a qotsitsoeng le ho rarolla lipelaelo tsa hau

nahanela.

3) Boleng bo phahameng - khampani e lula e paka ka pelo e tiileng hore lihlahisoa tseo e fanang ka tsona ke 100% ea boleng bo phahameng, e le hore u se ke ua tšoenyeha.

4) Ts'ebeletso ea kamora ho rekisa le tataiso ea tekheniki - re tla fana ka ts'ebeletso e ikhethileng ea motho ka mong le tataiso ea tekheniki ho latela litlhoko tsa hau.

Reamer, sesebelisoa sa bohlokoahali ho machining a nepahetseng, se bapala karolo ea bohlokoa ho fihlelleng litekanyo tse nepahetseng le liphetho tse boreleli mekoting e entsoeng ka mochini. E entsoe ka moralo o bonolo empa o rarahane, moqapi oa eona o fana ka mohlala oa boqapi bo hlokolosi bo batloang ke liindasteri tse fapaneng. A re ke re hlahlobeng boqhetseke ba sesebelisoa sena, re hlahlobe mesebetsi ea sona, ts'ebeliso le bohlokoa ba eona lefatšeng la machining.

Moralo le likarolo:

Reamer hangata e na le letoto la likarolo tse sehang tse hlophisitsoeng hammoho le 'mele oa cylindrical. Lithako tsa ho itšeha, hangata e le liphala tse otlolohileng kapa tsa helical, li etselitsoe ho tlosa thepa butle-butle ha sesebelisoa se ntse se potoloha. 'Mele oa reamer o entsoe ka tšepe ea lebelo le phahameng, carbide, kapa lisebelisoa tse ling tse tšoarellang, ho netefatsa nako e telele le ho tiea tlas'a maemo a boima a machining.

Mosebetsi:

Mosebetsi o ka sehloohong oa reamer ke ho hloekisa le ho holisa lesoba le chekiloeng pele. Ho fapana le liboro tse etsang masoba, li-reamers li fana ka mokhoa oa ho qetela, ho netefatsa hore lesoba le fihlela litlhoko tse nepahetseng tsa boholo. Ba tlosa liphoso leha e le life tse siiloeng ke mokhoa oa ho phunya, ho ntlafatsa ho nepahala le ho qeta holim'a sekoti se entsoeng ka mochine. Li-Reamers li tla ka mefuta e fapaneng, ho kenyelletsa le fluted e otlolohileng, e spiral-fluted, le e fetolehang, e 'ngoe le e' ngoe e etselitsoe ho khotsofatsa litlhoko tse ikhethang tsa mochini.

Lisebelisoa:

Ho feto-fetoha ha li-reamers ho fumana ts'ebetso indastering e mengata, ho kenyeletsoa sefofane, likoloi, tsa bongaka le tsa tlhahiso. Boenjiniere ba lifofane le likoloi, moo ho nepahala ho leng bohlokoa, li-reamer li thusa ho theha masoba bakeng sa likarolo tsa bohlokoa tse kang likarolo tsa enjene le li-fasteners. Lefapheng la bongaka, moo tlhahiso ea li-implant e hlokang ho nepahala ho hoholo, li-reamers li kenya letsoho ho theheng masoba bakeng sa likarolo tsa maiketsetso.

Precision Machining:

E 'ngoe ea litšoaneleho tsa bohlokoa tsa reamers ke bokhoni ba bona ba ho fihlela mamello e tiileng. Bo-machini ba itšetleha ka lisebelisoa tsena ho hlophisa litekanyo tsa lesoba hantle ka har'a meeli e moqotetsane haholo. Ho nepahala ho fanoang ke li-reamer ho bohlokoa indastering moo likarolo tsa eona li tlamehang ho hokahana hantle, ho netefatsa ts'ebetso e nepahetseng le bots'epehi ba sebopeho.

Mefuta ea li-Reamers:

Litlhoko tse fapaneng tsa mochini li lebisitse ho nts'etsopele ea mefuta e fapaneng ea li-reamer. Li-reamer tse nang le flute tse otlolohileng li loketse ts'ebeliso e akaretsang, ha li-spiral-fluted reaamers li sebetsa hantle haholo mesebetsing e hlokang hore chip e tlosoe hantle. Li-reamer tse feto-fetohang li fana ka maemo a bonolo ho fihlela boholo bo fapaneng ba lesoba ntle le tlhoko ea lisebelisoa tse ngata. Mofuta o mong le o mong o sebetsana le maemo a ikhethileng a machining, a bonts'a ho ikamahanya le maemo ha li-reamer maemong a fapaneng a indasteri.

Mathata le Litlhokomelo:

Le hoja li-reamer li le bohlokoa ho finyella ho nepahala, litsebi tsa mechine li tlameha ho nahana ka lintlha tse kang tlhophiso ea lisebelisoa, lebelo, le litekanyetso tsa lijo ho netefatsa ts'ebetso e nepahetseng. Ho boloka likarolo tse hlabang ho bohlokoa bakeng sa ho fumana sephetho se ts'oanang, 'me tlhahlobo ea nako le nako le ho khutlisa e fetoha karolo ea tlhokomelo e tloaelehileng ho ts'ehetsa ts'ebetso ea sesebelisoa.

Qetellong, reamer e eme e le bopaki ba ho nepahala ho batloang ke mekhoa ea morao-rao ea machining. Bokhoni ba eona ba ho ntlafatsa le boholo ba likoti tse entsoeng ka mochini ka ho nepahala le ho etsa hore e be motheo oa liindasteri moo boleng le ho nepahala li ke keng tsa buisanoa. Ha thekenoloji e ntse e hatela pele, reamer e ntse e tsoela pele ho fetoha, e ikamahanya le maemo a lulang a fetoha a tlhahiso le ho lula e le sesebelisoa sa bohlokoa ho lelekisa bokhabane ho machining a nepahetseng.