Source CNC tool ON Sale Good Quality DIN6388A Eoc Collets For Lathe

|

Product Name

|

EOC Collets

|

Hardness

|

HRC45-55

|

|

Precision

|

0.01mm

|

Clamping range

|

0-32mm

|

|

Warranty

|

3 Months

|

MOQ

|

10 Pcs

|

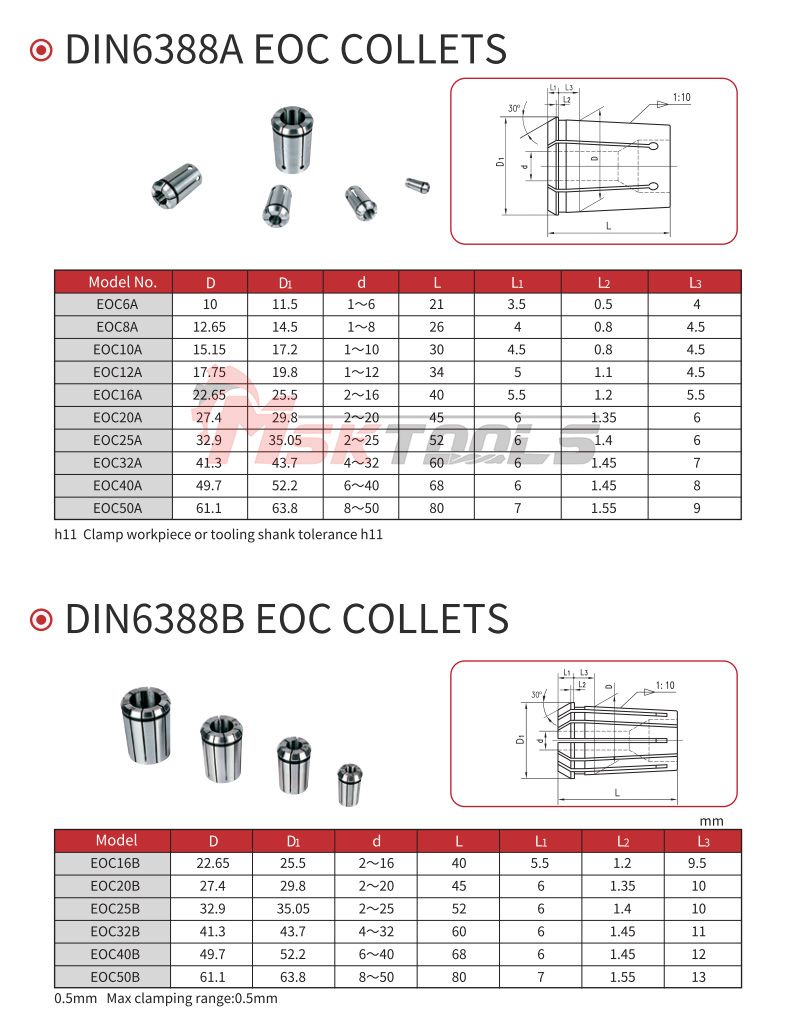

DIN 6388 EOC Collets: Versatile Toolholder Solutions for Precision Machining

Introduce:

In the world of precision machining, finding the right toolholder solution is critical to obtaining accurate and consistent results. DIN 6388 EOC collets are a versatile and reliable choice that are popular among professionals in a variety of industries. In this blog post, we will delve into the key features and benefits of these special collets, emphasizing their importance in achieving optimum performance and productivity.

1. What is a DIN 6388 EOC collet?

DIN 6388 EOC (Eccentric Operating Collet) collets are widely recognized for their superior grip, concentricity and adaptability. Manufactured to the exacting standards of the German Institute for Standardization (Deutsches Institut für Normung), these collets are designed to provide secure clamping of cylindrical workpieces, ensuring precision and repeatability throughout the machining process.

2. Versatility and compatibility:

One of the main advantages of DIN 6388 EOC collets is their compatibility with various tooling systems such as BT, SK and HSK. This allows manufacturers, regardless of their specific machine type, to use these chucks seamlessly, eliminating the need for costly modifications or multiple tooling systems. With its wide size range and clamping capabilities, DIN 6388 EOC collets can accommodate a wide range of workpiece sizes, making them a versatile choice for different machining applications.

3. Super strong clamping force:

The superior holding force of DIN 6388 EOC collets is due to their unique eccentric design. This design improves rigidity and concentricity during machining, minimizing vibration and runout. The precision ground shaft of the collet ensures a secure clamping, prevents slippage and guarantees optimum tool stability. This strong clamping force improves machining accuracy, reduces tool wear and increases overall productivity.

4. Quick tool change:

Efficiency and time savings are two key factors in modern machining operations. The DIN 6388 EOC collet excels in both aspects with its quick change feature. User-friendly design allows for easy tool changes, reducing downtime and increasing productivity. The compatibility of collets with automatic tool changers further enhances their seamless integration with advanced machining systems, ensuring a smooth workflow.