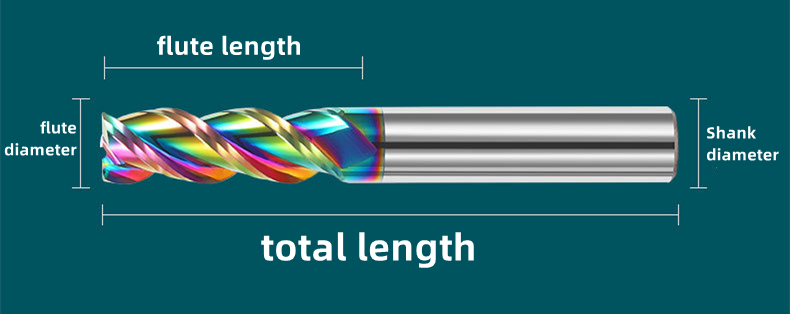

Solid Carbide 3 Flutes DLC Coated End Mills For Aluminum

Features

1. Sharp edge

High-precision grinding process to reduce vibration

Not easy to break the knife, can play a long life

2.35° helix angle

Usually the choice of material processing, the helix angle is small and the cutting is good, which can meet the roughing, large allowance processing or processing of relatively soft materials

3. High quality bar stock

Selected high-quality bars, exquisite craftsmanship, greatly improve the service life of the tool

4. Large chip flute

Unequal helix + large chip flute design makes chip breaking and chip removal fast, and achieves high productivity in cutting

5. Coating

Using high-quality coating technology

Different series of different coatings, easy to distinguish

6. Chamfer design

The bottom chamfer design is easier to operate when clamping, and the clamping is more smooth

7.Tungsten steel material, with higher wear resistance and hardness, sufficient toughness and wear resistance, more durable

Committed to high-quality tungsten steel milling cutter

High efficiency, long life and wide range of applications

Suggest

01 Appropriately reduce the cutting speed and feed rate, which can prolong the service life of the milling cutter.

02 When working, it is necessary to add cutting fluid to protect the knife edge and make the cutting smoother

03 When there is residual oxide film or other hardened layer on the surface of the workpiece, it can be removed by reversible milling