Tungsten Carbide Flow Drill Bit

SHARAXA Alaabada

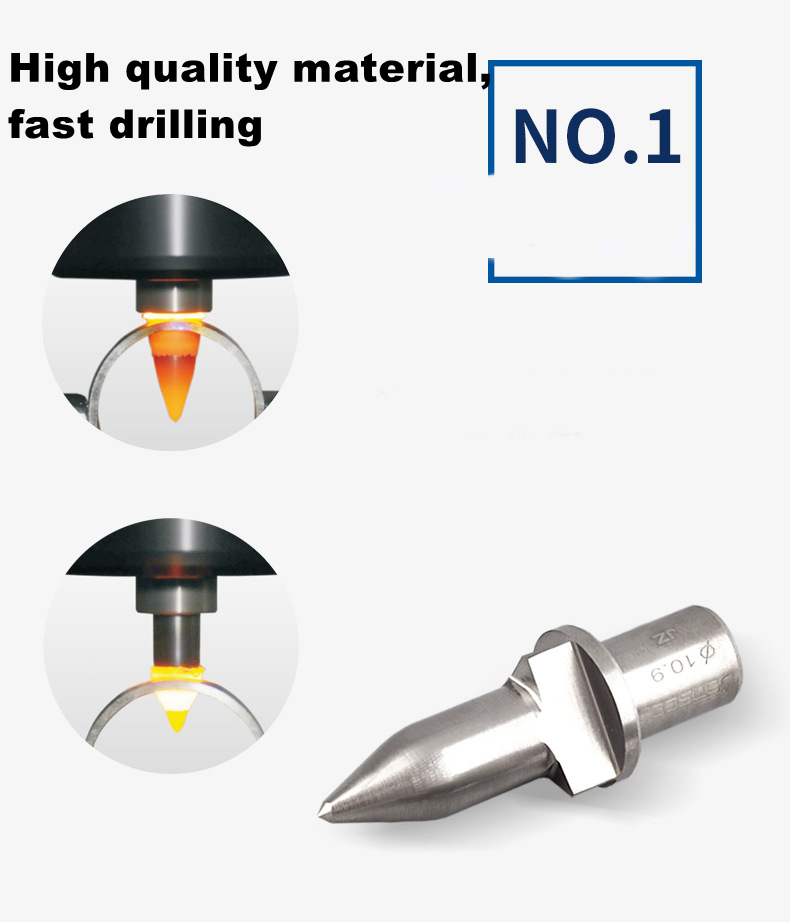

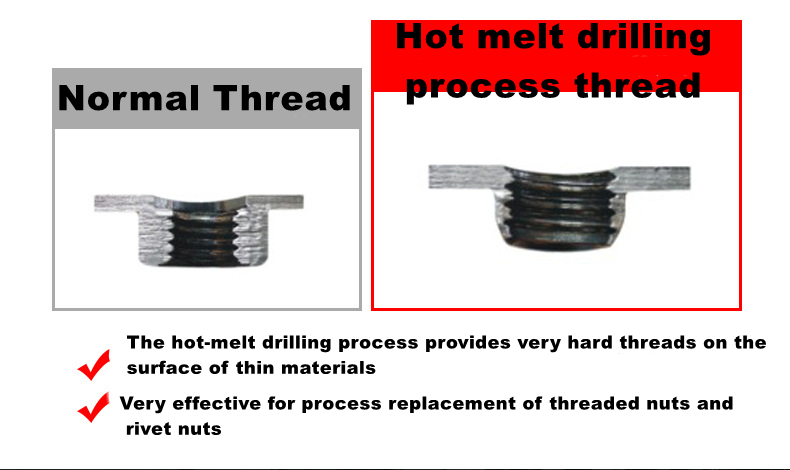

Mabda'a qodista dhalaalka kulul

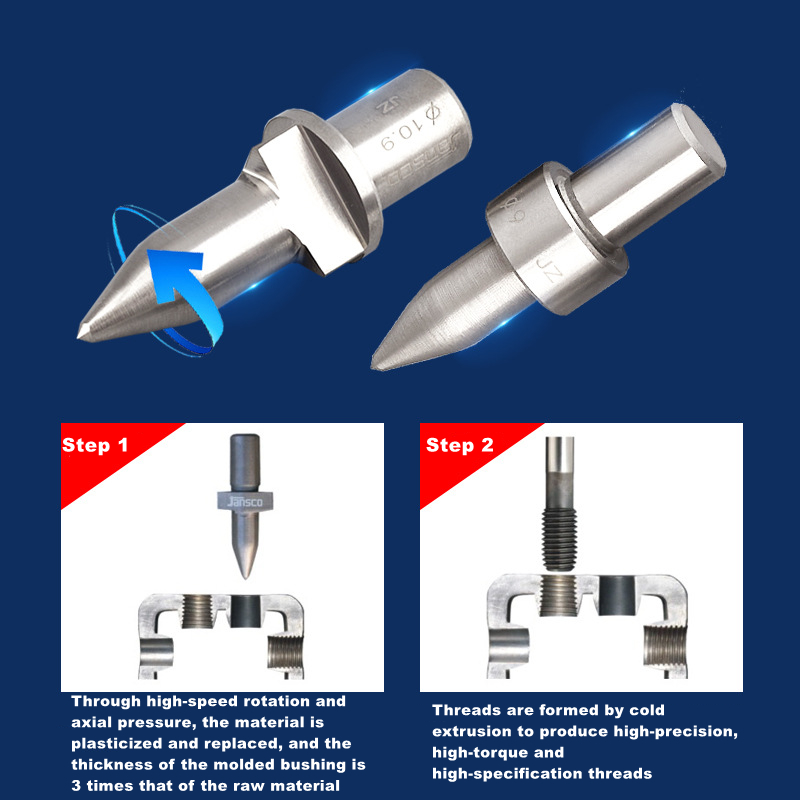

Daloolin-kuleylku wuxuu abuuraa kulayl iyada oo loo marayo wareegga-xawaaraha sare leh iyo cadaadiska dhididka si loo balaajiyo oo loogu beddelo alaabta. Isla markaa, waxa ay feedhtaa oo ay samaysaa kaynta qiyaastii 3 jeer dhumucda alaabta ceeriin, oo ay sii dayso oo ay tuubbada dhex marto si ay ugu samayso walxaha khafiifka ah. Xadhkaha sare ee saxda ah, xoogga sare.

TALO LAGU ISTICMAALO IN LAGU ISTICMAALO MUUQAALADA SHAQADA

Tallaabada ugu horreysa: balaastiigga walxaha iyada oo loo marayo wareegga xawaaraha sare iyo cadaadiska axial. Dhumucdiisuna waxay ka badan tahay 3 jeer alaabta ceeriin.

Talaabada labaad: duntu waxa ay samaysaa qashin qabow si ay u soo saarto saxsanaan sare, torque-sare iyo heer saren dunta

| Summada | MSK | Dahaarka | No |

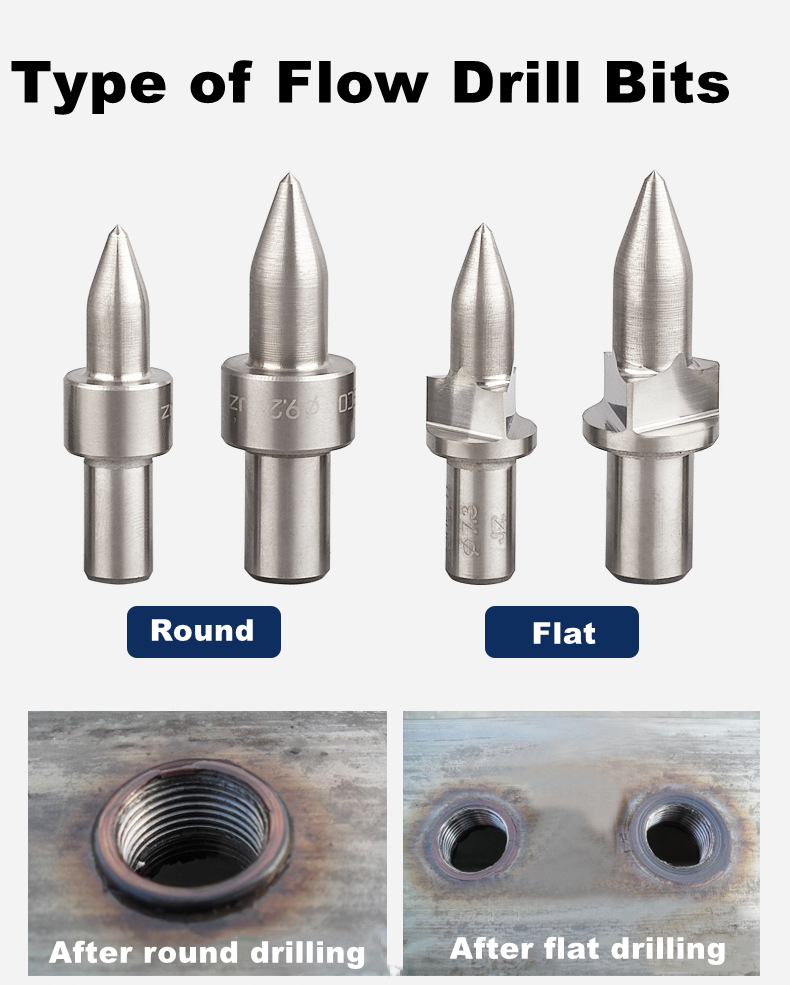

| Magaca Alaabta | Dejinta jajabka kuleylka kuleylka | Nooca | Nooca siman/wareega |

| Qalab | Carbide Tungsten | Isticmaal | qodista |

MUUQAAL

Taxadirrada isticmaalka laylinta kulul ee kulul:

1. Qalabka Workpiece: laydhka kulul ee dhalaalay waxay ku habboon yihiin qalabka birta ee kala duwan ee leh dhexroorka 1.8-32mm iyo dhumucdiisuna tahay 0.8-4mm, sida birta, birta khafiifka ah, birta aan fiicnayn, titanium, aluminium, copper, copper, naxaas (content Zn in ka yar 40%), aluminium aluminium (Si content in ka yar 0.5%), iyo wixii la mid ah ayaa dhalaalay nolosha qaro weyn.

2. Kuleyl-dhalaalaya: Marka laydhka-kuleelka ahi uu shaqaynayo, heerkul sare oo ka badan 600 digrii ayaa isla markiiba soo baxaya. Koofiyada khaaska ah ee kululaynta kulul waxay sii dheerayn kartaa nolosha adeegga laydhka kulul, hagaajinta tayada gudaha gudaha ee dhululubada, waxayna soo saartaa qaab cidhif ah oo nadiif ah oo lagu qanco. Waxaa lagu talinayaa in lagu daro qadar yar oo ah koollada kulul ee qalabka 2-5 godad kasta oo lagu qodo birta kaarboonka ee caadiga ah; for workpieces ahama, dalool kasta oo la qoday, ku dar koollada kulul by gacanta; Maaddadu dhumucdeeduna way sii adkaanaysaa, way badanaysaa inta jeer ee isku-darka.

3. Shanka iyo jeexjeexa laydhka dhalaalidda kulul: Haddii aanay jirin meel kulayl gaar ah, isticmaal hawo cufan si aad u qaboojiso.

4. Qalabka mashiinka qodista: ilaa inta mashiinada qodista kala duwan, mishiinnada wax lagu shubo iyo xarumaha mashiinada ee leh xawaaraha iyo awoodda ku habboon ay ku habboon yihiin qodista kuleylka kuleylka; Dhumucda maaddada iyo farqiga u dhexeeya walxaha laftiisa ayaa dhammaantood saameeya go'aaminta xawaaraha wareegga.

5. Godad hore loo sii farsameeyay: Iyadoo hore loo sii qodayo dalool yar oo bilaw ah, qallafsanaanta shaqada waa laga fogaan karaa. Daloollada hore loo sii diyaariyey waxay yareyn karaan xoogga axial-ka iyo joogga dhululubada, waxayna sidoo kale soo saari karaan cidhif fidsan oo ku taal cidhifka ugu hooseeya ee dhululubada si looga fogaado qallooca qallooca ee derbiyada khafiifka ah (in ka yar 1.5mm).

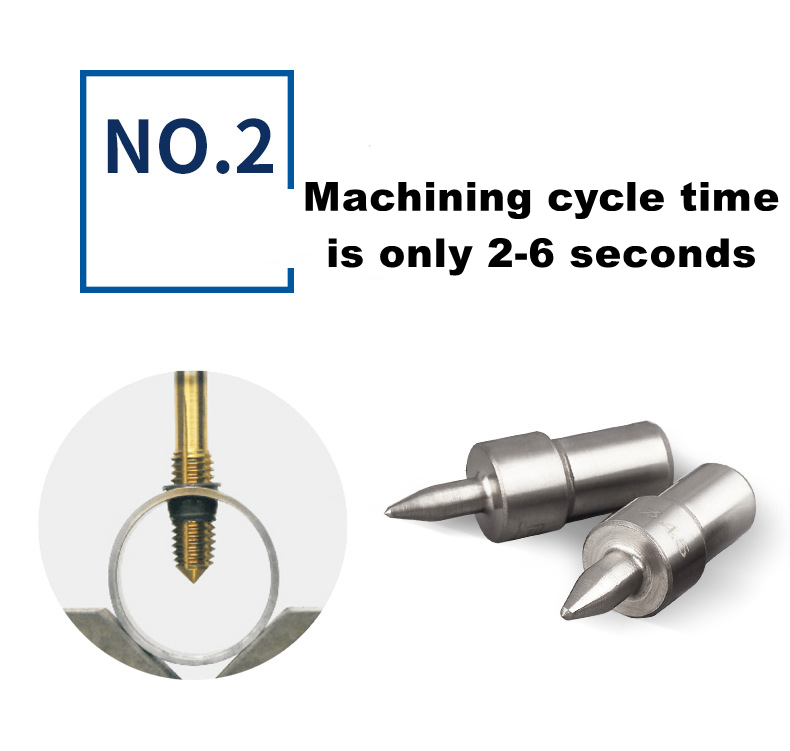

6. Marka aad tuubbada, isticmaal saliid tuubada: waxaa lagu talinayaa in la isticmaalo qasabadaha extrusion, kuwaas oo aan samayn goynta laakiin extrusion, si ay u leeyihiin awood adag oo sare iyo qiimaha torsion. Waxa kale oo suurtogal ah in la isticmaalo qasabadaha wax lagu gooyo ee caadiga ah, laakiin way fududahay in la gooyo dhululubada, iyo dhexroorka daloolka kululaynta ayaa ka duwan oo loo baahan yahay in si gaar ah loo sameeyo.

7. Dayactirka laydhka dhalaalinta kulul: Ka dib marka la isticmaalo laydhka kulul ee kuleyl ah in muddo ah, dusha ayaa la gashan doonaa, iyo qaar ka mid ah koollada kulul ee dhalaalay ama wasakhda shaqada ayaa lagu dhejin doonaa jirka gooya. Ku dheji daloolinta kulul ee mishiinka laysaga ama wax-shiidka, oo ku shiid koolada xoqan. Ha u fiirsan badbaadada.