Warshada Radius-ka galleyda ee loo yaqaan 'Nickel-based High-Temp Alloys'

SHARAXA Alaabada

Titanium waa shay aad u adag in la makiinado, gaar ahaan wadooyin qallafsan, sida kuwa la xidhiidha Milling Efficiency High (HEM). Gooyaha radius-ka ee geeska waxa si gaar ah loogu isticmaalaa habaynta agabka warshadaha duulista. Waxay qabataa kaydka birta tungsten ee dibadda laga keeno waxayna leedahay nolol adeeg dheer.

TALO LAGU ISTICMAALO IN LAGU ISTICMAALO MUUQAALADA SHAQADA

Titanium alloy TC18-21, ferrite, alloy-nickel-ka sarreeya ee ka sarreeya 35%, birta heerkulka sare leh, nikkel-chromium-cobalt iyo kuwa kale oo adag in la gooyo qalabyada titanium-ka sarreeya, qalabyada heerkulka sare leh.

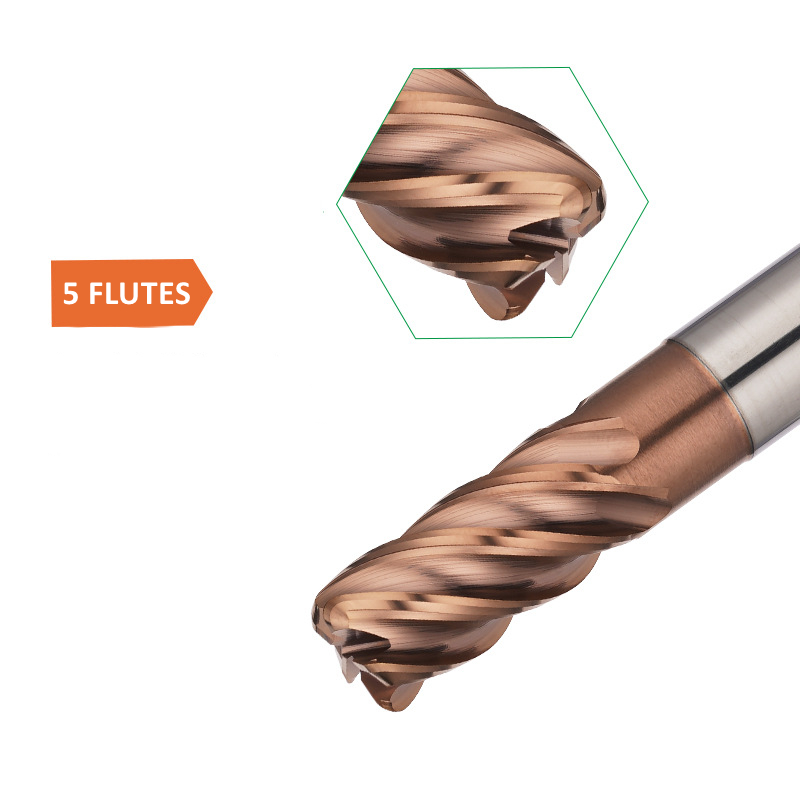

Naqshadaynta 5-flute waa 30% -40% ka dhakhso badan 3-flute/4

Naqshad Seismic/Heerka saarista birta sare ee aadka u saraysa/cadawiska gudaha hoose

| Dhexroorka hargabka | D6-D12 | Dhererka hargabka | 8-24mm |

| Nooca hargabka | Helical | Qalab | tungsten heer sare ah |

| Dahaarka | Haa | Summada | MSK |

| Range Processing | Qalab adag in la gooyo sida titanium alloys, superalloys, ferrites, jirka nikkel, birta aan heerkulka sare lahayn, iyo nikkel-chromium-cobalt. | ||

| Mashiinnada lagu dabaqi karo | Mashiinnada wax-shiidka, xarumaha mashiinnada CNC, gongyada kombuyuutarka, mashiinnada xaradhka | ||

MUUQAAL

1.Special ee Titanium/superalloy ay adag tahay in la gooyo

Lagu qalabeeyay dufan sare iyo dahaar iskuxiran oo hooseeya si loo yareeyo walbahaarka gudaha ee walaxda warshadaysan.

2.Geometry Flute

Naqshad joomatari 5-blade U-groove ah oo aad u fiican ayaa kordhin karta barta xiriirka ee walxaha la farsameynayo, iyadoo la kordhinayo qallafsanaanta aaladda iyo hubinta qallafsanaanta dusha sare.

3. Birta tungsten laga keeno

Saxnaanta dulqaadka Shank ee H5, oo si gaar ah loogu talagalay nidaamyada xakamaynta shank ee saxda ah.

4.Chamfer design

U fududee in lagu dhejiyo.

5.Seismic Design

Heerka saarista birta aadka u saraysa, diiqad hoose oo hoose, 30% -40% ka dhakhso badan 3-blade/4

Codsiga:

Hawada hawada, ciidamada, qaybaha makaanikada, baabuurta, isgaarsiinta elektiroonigga ah ee gaarka ah iyo goobo kale

Xusuusta iibsadaha:

1. Kahor intaadan isticmaalin qalabka, fadlan cabbir leexinta qalabka. Marka saxnaanta leexinta aaladda ay dhaafto 0.01mm, fadlan sax ka hor intaanad jarin.

2. Dhererka gaaban ee qalabka oo ka soo baxa chuck, ayaa ka sii fiican. Haddii qalabku sii dheeraado, xawaaraha, heerka quudinta iyo qadarka goynta ayaa loo baahan yahay in la dhimo.

3. Inta lagu jiro goynta, haddii gariirka aan caadiga ahayn ama dhawaaqa uu dhaco, fadlan yaree xawaaraha iyo goynta ilaa ay xaaladdu ka soo raynayso.

4. Qaboojinta birta ayaa la doorbidayaa buufinta iyo jet-ka hawada, taas oo hagaajin karta saameynta isticmaalka qashinka. Alloys Titanium iyo kuwa kale ee superalloys laguma talinayo.