Hrc65 Carbide 4 Rut gees gees geesood ah

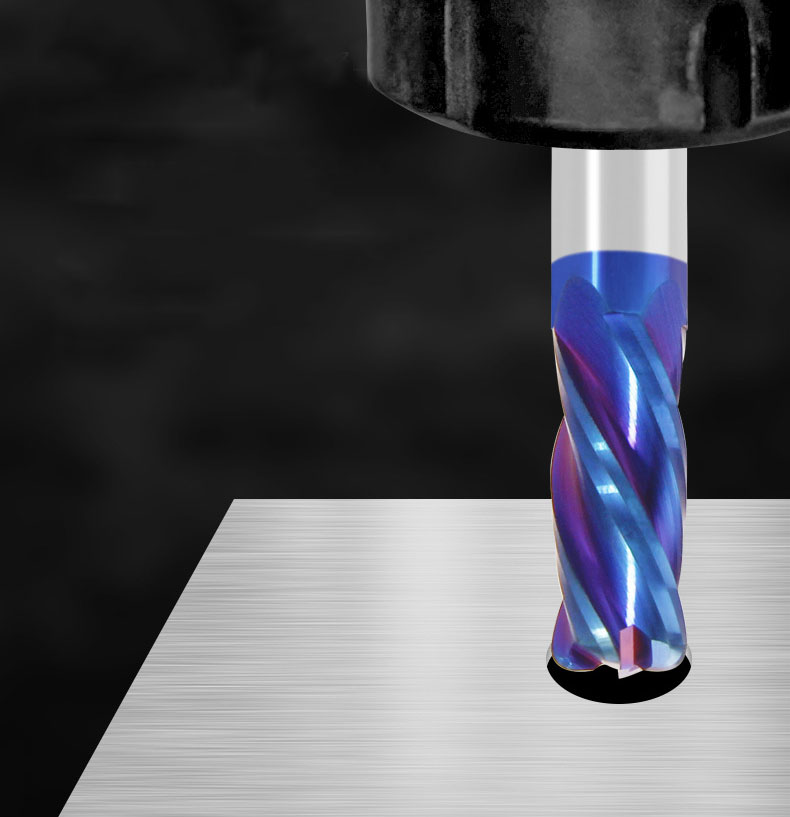

Sharraxaadda Wax soo saarka

Darajooyinka wax soo saarka: Darajada buluuga ah ee Nano

Qalabka wax soo saarka: bir tayo sare leh oo bir ah

Qalabka Mashiinka Qalabka ee lagu dabaqi karo

Goynta sheyga: bir bir ah, bir bir ah, bir bir ah, bir yar, bir bir ah iyo waxyaabo kale

Tilmaamaha ugu muhiimsan: Isticmaalka walxaha ganaax cusub oo bir ah oo bir ah, xidho iska caabbinta iyo adkeed, dhamaad wanaagsan, caabbinta wanaagsan, caabbinta fiiqan, iyo si sax ah oo saameyn wanaagsan leh, saameyn wanaagsan.

Talo soo jeedin loogu talagalay in lagu isticmaalo aqoon isweydaarsiga

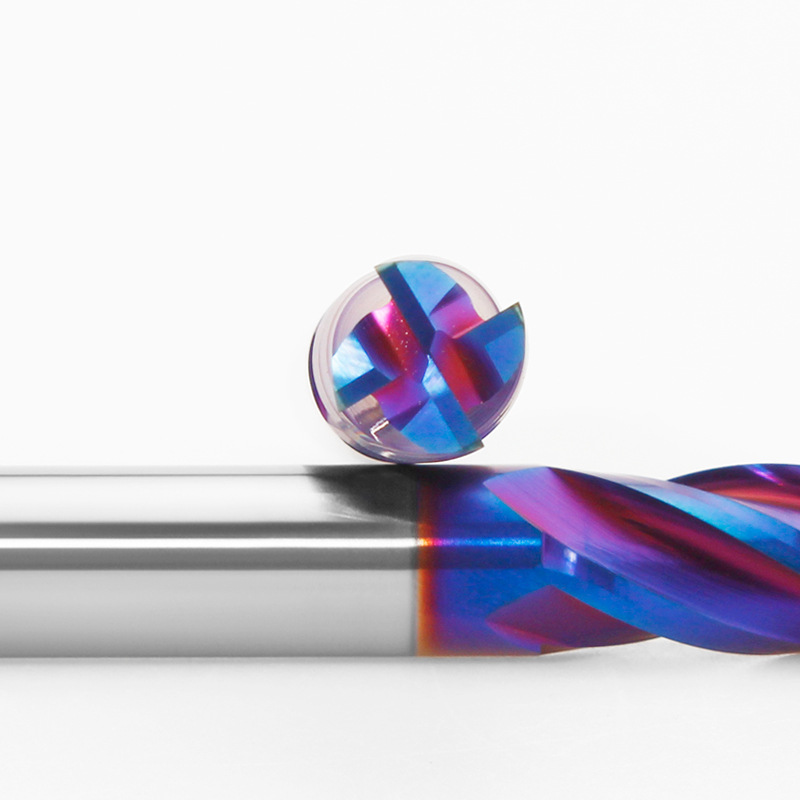

1. Naqshadeynta chipka chip-ka wareega ayaa ah mid aad u wanaagsan oo ku habboon bixinta qashinka wasakhda, ka hortagga aaladda inay ku dhejiso aaladda, oo ay si weyn u wanaajinayso waxtarka wax soo saarka

2. Xanuunka lagu hubinayo booska chip, waxaa si weyn u dhigeysa qaab-dhismeedka weyn ee xudunta weyn ee loo yaqaan 'Chipereters' oo si weyn u xoojineysa adkaynta aaladda oo uu sii dheeraado nolosha adeegga

| Summad | Mark | Magac | Dhamaadka geeska geeska jumlo |

| Adkayn | Hrc65 | Xagal Hillx xagal | 35 digrii |

| Mashiin lagu dabaqi karo | Xarumaha farsamada ee CNC, mashiinnada wax lagu qoro, mashiinnada wax lagu qoro iyo makiinadaha kale ee xawaaraha sare | ||

Faa'iido

Qeyb: dahaadhka altisan, oo ah daaha nanotechnology, adag ilaa 4000hv, xasilloonida kuleylka ee 1200 "c

Qiyaasta guud ee goynta guud:

Jarida xawaaraha VC = 220 (100-800) m / min

Jarida qoto dheer ap = l / 20 (l / 8-3 / 40)

Joojinta ballaca Ae = L / 2 0 (L / 4-10)

Quudinta hal-dadaalka ah F: = 0.15mm (0.02-0.2)

Qiyaasta goynta waa in si sax ah loogu habeeyaa iyadoo loo eegayo agabyada kala duwan iyo adkaanta agabyada la warshadeeyay.

Tilmaamaha ugu muhiimsan: oo leh xagal fidsan oo ah 35 digrii, waxay leedahay laqabsasho adag oo loo adeegsado agabka iyo adkaanta agabyada la warshadeeyay. Waxaa si weyn loogu isticmaalaa caaryada iyo wax soo saarka badeecada, oo leh wax qabad qaali ah. Geeska waa la xumaanayaa, ma fududa in la dilaa, waxaana si weyn loogu isticmaalaa mashiinka xawaaraha sare leh.

Maxaad u dooranaysaa: garabka fiiqan; hagaajinta hufnaanta; xoog badan oo adag; qaybo dhameystiran; ashyaa tayo sare leh;

XUQUUQDA:

| Shayga no. | Dhexroor d | R | Dhererka goynta | Dhexroor sharooto | Dhererka guud | Duubid |

| Msk4fb001 | 4 | 0.5 | 10 | 4 | 50 | 4 |

| Msk4fb002 | 4 | 1 | 10 | 4 | 50 | 4 |

| Msk4fb003 | 5 | 0.5 | 13 | 5 | 50 | 4 |

| Msk4fb004 | 5 | 1 | 13 | 5 | 50 | 4 |

| Msk4fb005 | 6 | 0.5 | 15 | 6 | 50 | 4 |

| Msk4fb006 | 6 | 1 | 15 | 6 | 50 | 4 |

| Msk4fb007 | 8 | 0.5 | 20 | 8 | 60 | 4 |

| Msk4fb008 | 8 | 1 | 20 | 8 | 60 | 4 |

| Msk4fb009 | 8 | 2 | 20 | 8 | 60 | 4 |

| Msk4fb010 | 8 | 3 | 20 | 8 | 60 | 4 |

| Msk4fb011 | 10 | 0.5 | 25 | 10 | 75 | 4 |

| Msk4fb012 | 10 | 1 | 25 | 10 | 75 | 4 |

| Msk4FB013 | 10 | 2 | 25 | 10 | 75 | 4 |

| Msk4FB014 | 10 | 3 | 25 | 10 | 75 | 4 |

| Msk4FB015 | 12 | 0.5 | 30 | 12 | 75 | 4 |

| Msk4fb016 | 12 | 1 | 30 | 12 | 75 | 4 |

| Msk4fb017 | 12 | 2 | 30 | 12 | 75 | 4 |

| Msk4fb018 | 12 | 3 | 30 | 12 | 75 | 4 |

| Msk4fb019 | 14 | 0.5 | 35 | 14 | 100 | 4 |

| Msk4FEM420 | 14 | 1 | 45 | 14 | 100 | 4 |

| Msk4fb021 | 16 | 0.5 | 45 | 16 | 100 | 4 |

| Msk4FB022 | 16 | 1 | 45 | 16 | 100 | 4 |

| Msk4fb023 | 18 | 0.5 | 45 | 18 | 100 | 4 |

| Msk4FB024 | 18 | 1 | 45 | 18 | 100 | 4 |

| Msk4fb025 | 20 | 0.5 | 45 | 20 | 100 | 4 |

| Msk4fb026 | 20 | 1 | 45 | 20 | 100 | 4 |