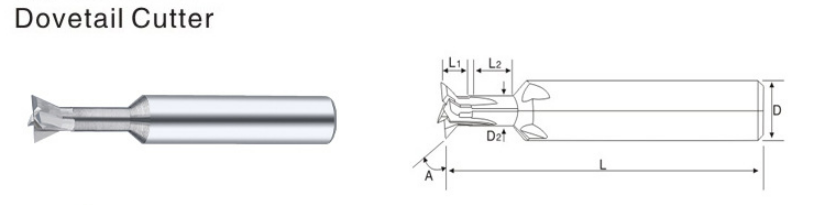

Tungsten Carbide Dovetail Milling Cutters Tool

Chinhu chose chakagadzirwa nemhando yepamusoro tungsten simbi, ine kuomarara kwepamusoro uye kushomeka kwepamusoro. Iko kushandiswa kwepamusoro pekuita alloy simbi zvinhu, ine yakanaka seismic resistance.Iyo yakagadzirwa neyakaomeswa-grained tungsten simbi mbariro, iyo ine yakakwirira kupfeka kuramba uye simba. Iyo yemhando yepamusoro dovetail banga repamusoro-kuoma kwepamusoro-kumhanya kucheka maapplication. Inogona kuita yakakwirira-kumhanya kugadzirisa pasimbi isina tsvina, aluminium alloy, cast iron uye zvimwe zvinhu pazasi HRC55 (kusanganisira HRC55). Machining, kuderedza huwandu hwekuchinja kwechishandiso nekuvandudza kugona

Advantage:

Inodhura-inoshanda uye isu tinosarudza yakakwirira-yemhando tungsten simbi ine yakakwirira kuoma uye yakakwirira kupfeka kuramba

Precision muchina kuvaka, kugaya zvakanaka. Precision processing, shoma burrs mukugadzirwa kwechigadzirwa-yakanyanya kutsvedzerera

Kudzora kwemhando yepamusoro, kurongeka kwepamusoro uye kwakapinza zvigadzirwa zvakapedzwa

Feature:

1. Makona akapinza anonatsiridza zvakanyanya kucheka

2. Straight groove design, smooth chip evacuation pasina kunamatira banga

3. Zvinonzwisisika dzivisa mhepo uye uwedzere hupenyu hwekushandisa

4. Simbisa kusimba kwekucheka, uye bhanhire re arc rinofambisa kumucheto wakapinza uye zvinobudirira kubvisa burr.

5. Iyo huru yekukwanisa chip kubvisa groove inocheka simba, uye kucheka kunowedzera kutsetseka, kuwana hukuru hwekugadzirisa machining, uye workpiece yakanyatsojeka uye inotyisa.

| Type | Tungsten Dovetail Milling Cutter | Material | Tungsten Steel |

| Workpiece Material | Simbi isina tsvina, aruminiyamu, simbi inofa, simbi yakakandwa, aruminiyamu alloy, alloy simbi, titanium alloy, nezvimwe. | Inoshanda muchina chishandiso | CNC machining Center, CNC muchina chishandiso, muchina wekunyora, muchina wekuveza, muchina unomhanya kwazvo. |

| Transport Package | Bhokisi | Nyere | 3/4 |

| Coating | No | Kuoma | <=55 |

| Nyere Dyamita(mm) | D2(mm) | L2(mm) | Nyere urefu(mm) | Shank Diameter(mm) | Hurefu Hwose(mm) | Nyere |

| 3 | 1.5 | 5 | 0.7 | 3 | 50 | 3 |

| 4 | 2 | 6 | 1 | 4 | 50 | 3 |

| 5 | 2.5 | 8 | 1.2 | 5 | 50 | 3 |

| 6 | 3 | 8 | 1.5 | 6 | 50 | 3 |

| 7 | 3.5 | 10 | 1.7 | 7 | 50 | 4 |

| 8 | 4 | 10 | 2 | 8 | 50 | 4 |

| 9 | 4.5 | 15 | 2.2 | 9 | 60 | 4 |

| 10 | 5 | 15 | 2.5 | 10 | 60 | 4 |

| 11 | 5.5 | 15 | 2.7 | 11 | 60 | 4 |

| 12 | 6 | 15 | 3 | 12 | 60 | 4 |

| 16 | 8 | 20 | 4 | 16 | 65 | 4 |

| 20 | 10 | 25 | 5 | 20 | 75 | 4 |

| 3 | 1.5 | 5 | 1.4 | 3 | 50 | 3 |

| 4 | 2 | 6 | 1.7 | 4 | 50 | 3 |

| 5 | 2.5 | 8 | 2.1 | 5 | 50 | 3 |

| 6 | 3 | 8 | 2.6 | 6 | 50 | 3 |

| 7 | 3.5 | 10 | 3 | 7 | 60 | 4 |

| 8 | 4 | 10 | 3.4 | 8 | 60 | 4 |

| 9 | 4.5 | 15 | 3.8 | 9 | 60 | 4 |

| 10 | 5 | 15 | 4.3 | 10 | 60 | 4 |

| 11 | 5.5 | 15 | 4.7 | 11 | 60 | 4 |

| 12 | 6 | 15 | 5.2 | 12 | 60 | 4 |

| 16 | 8 | 20 | 6.9 | 16 | 65 | 4 |

| 20 | 10 | 25 | 8.6 | 20 | 70 | 4 |

| 3 | 1.5 | 5 | 2.7 | 3 | 50 | 3 |

| 4 | 2 | 6 | 3.7 | 4 | 50 | 3 |

| 5 | 2.5 | 8 | 4.6 | 5 | 50 | 3 |

| 6 | 3 | 8 | 5.5 | 6 | 50 | 3 |

| 7 | 3.5 | 10 | 6.5 | 7 | 60 | 4 |

| 8 | 4 | 10 | 7.4 | 8 | 60 | 4 |

| 9 | 4.5 | 15 | 8.3 | 9 | 60 | 4 |

| 10 | 5 | 15 | 9.3 | 10 | 60 | 4 |

| 11 | 5.5 | 15 | 10.2 | 11 | 60 | 4 |

| 12 | 6 | 15 | 11.1 | 12 | 60 | 4 |

| 16 | 8 | 20 | 14.9 | 16 | 65 | 4 |

| 20 | 10 | 25 | 18.6 | 20 | 75 | 4 |

Shandisa:

Inoshandiswa zvakanyanya mundima dzakawanda

Aviation Manufacturing

Machine Production

Mugadziri wemotokari

Kugadzira mold

Electrical Manufacturing

Lathe processing