Sechishandiso chakajairika chekugadzirisa tambo dzemukati, matepi anogona kupatsanurwa kuita spiral groove tap, edge inclination tap, yakatwasuka groove tepi uye pombi tambo tepi zvinoenderana nechimiro chadzo, uye inogona kupatsanurwa kuita tepi dzemaoko uye matepi emuchina zvinoenderana nenharaunda yekushandisa. Yakakamurwa kuita metric, American, uye imperial tap. Unovaziva vese here?

01 Tap classification

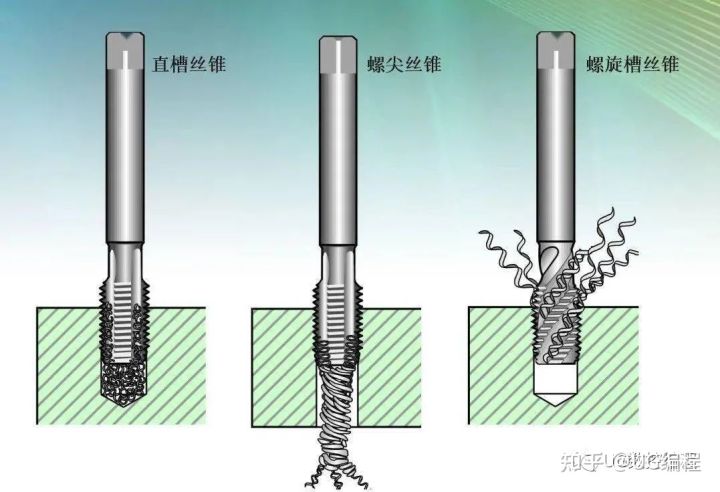

(1) Kucheka matepi

1) Nyore nyere pombi: inoshandiswa kugadzirisa kuburikidza nemakomba nemapofu mapofu, machipisi esimbi aripo mupombi groove, mhando yeshinda yakagadziriswa haina kukwirira, uye inonyanya kushandiswa kugadzirisa zvipfupi chip zvinhu, senge grey cast iron, nezvimwe.

2) Spiral groove tap: Inoshandiswa kugadzira gomba remapofu nekudzika kwegomba kushoma kana kuenzana ne3D, mafirita esimbi anoburitswa achitevedza spiral groove, uye shinda pamusoro pemhando yepamusoro.

10 ~ 20 ° helix angle tap inogona kugadzirisa kudzika kweshinda kudarika kana kuenzana ne2D;

28 ~ 40 ° helix angle tap inogona kugadzirisa kudzika kweshinda kudarika kana kuenzana ne3D;

Iyo 50 ° helix angle tap inogona kugadzirisa kudzika kweshinda kudarika kana kuenzana ne3.5D (special working condition 4D).

Mune zvimwe zviitiko (zvakaoma zvinhu, gombe hombe, nezvimwewo), kuitira kuti uwane simba remazino riri nani, helical flute tap inoshandiswa muchina kuburikidza nemakomba.

3) Spiral point tap: inowanzo shandiswa chete kuburikidza nemakomba, kureba-dhayamita reshiyo inogona kusvika 3D ~ 3.5D, machipisi esimbi anoburitswa pasi, torque yekucheka idiki, uye mhando yepamusoro yeshinda yakagadzirwa yakakwira, inozivikanwawo se edge angle tap kana apex tap.

Paunenge uchicheka, zvinodikanwa kuve nechokwadi kuti zvikamu zvese zvekucheka zvakapinda, zvikasadaro kubvongodza mazino kuchaitika.

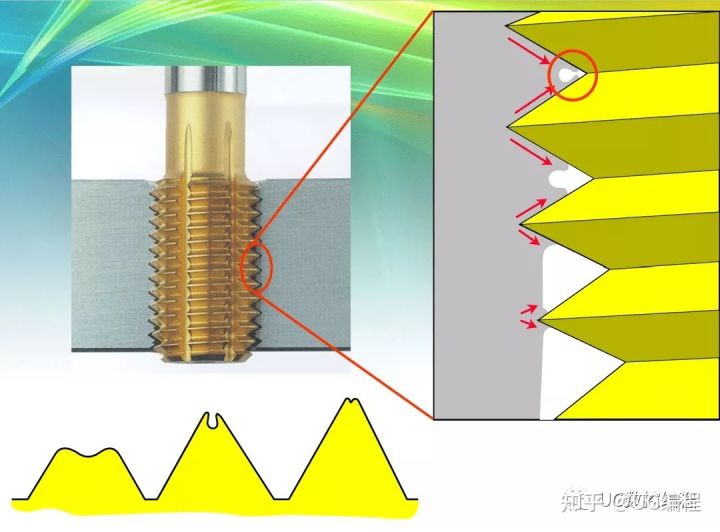

(2) Extrusion tap

Inogona kushandiswa kugadzirisa kuburikidza nemakomba uye mapofu mapofu, uye chimiro chezino chinoumbwa nepurasitiki deformation yezvinhu, iyo inogona kushandiswa chete kugadzirisa zvinhu zvepurasitiki.

Zvimiro zvayo zvikuru:

1) Shandisa purasitiki deformation yeworkpiece kugadzirisa shinda;

2) Nzvimbo yepamuchinjikwa yepombi yakakura, simba rakakwirira, uye haisi nyore kuputsa;

3) Kumhanya kwekucheka kunogona kuve kwakakwira kupfuura iyo yekucheka matepi, uye kubereka kunowedzerwawo zvinoenderana;

4) Nekuda kwekutonhora kweextrusion process, ma mechanic properties yeiyo yakagadziridzwa tambo yepasi inovandudzwa, kushata kwepamusoro kwakakwira, uye kusimba kweshinda, kupfeka kuramba uye kushorwa kunovandudzwa;

5) Chipless machining.

Kukanganisa kwayo ndiko:

1) inogona kushandiswa chete kugadzira zvinhu zvepurasitiki;

2) Mutengo wekugadzira wakakwira.

Pane mafomu maviri ekuumbwa:

1) Extrusion matepi asina mafuta grooves anongo shandiswa vertical machining yemapofu maburi;

2) Mapombi ekuwedzera ane grooves yemafuta akakodzera kune ese ekushanda mamiriro, asi kazhinji madiki madhiyamita matepi haagadziri magirofu emafuta nekuda kwekunetsa kwekugadzira.

(1) Zvimiro

1) Hurefu hwakazara: Teerera kune mamwe mamiriro ekushanda anoda kurebesa kwakakosha

2) Slot urefu: kupfuura kumusoro

3) Shank: Parizvino, iyo yakajairika shank miyero ndeye DIN (371/374/376), ANSI, JIS, ISO, etc. Pakusarudza, teerera kune hukama hwehukama netapping shank.

(2) Chikamu chine thread

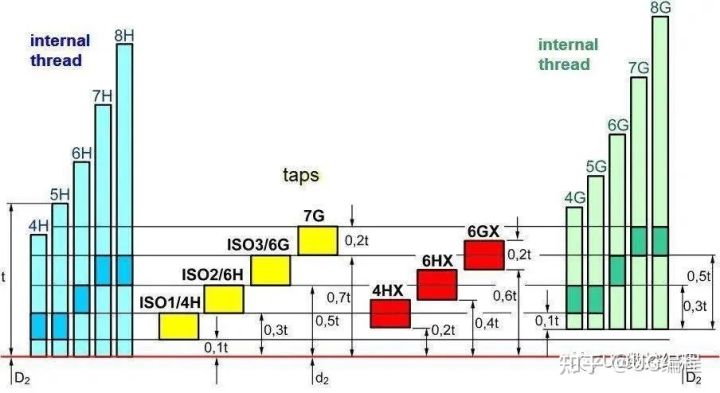

1) Kurongeka: Inosarudzwa neiyo chaiyo tambo standard. Iyo metric thread ISO1/2/3 nhanho yakaenzana neyenyika chiyero H1/2/3 nhanho, asi zvinodikanwa kuterera kune mugadziri wemukati wekutonga zviyero.

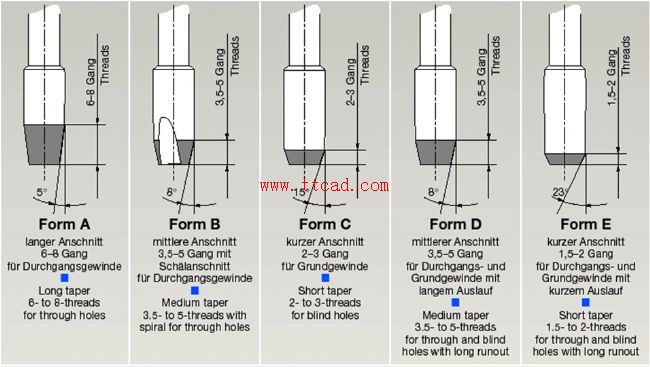

2) Kucheka pombi: Chikamu chekucheka chepombi chakagadzira chikamu cheiyo yakagadziriswa pateni. Kazhinji, kureba kwepombi yekucheka, hupenyu hwepombi huri nani.

3) Mazino ekugadzirisa: Inotamba basa rekubatsira uye kugadzirisa, kunyanya mumamiriro asina kugadzikana ekugadzirisa hurongwa, kunyanya kugadzirisa mazino, kunowedzera kupikisa.

(3) Chip nyere

1. Groove type: Inobata kuumbwa uye kubudiswa kwesimbi filings, iyo inowanzova chakavanzika chemukati chemugadziri wega wega.

2. Rake angle uye kona yekuyamura: kana pombi ichiwedzerwa, pombi inova yakapinza, iyo inogona kuderedza zvakanyanya kushorwa kwekucheka, asi simba uye kugadzikana kwezino rezino kunoderera, uye kona yekuyamura ndiyo kona yekurerutsira.

3. Nhamba ye grooves: nhamba ye grooves inowedzera uye nhamba yekucheka mitsetse inowedzera, iyo inogona kubudirira kuvandudza hupenyu hwepombi; asi ichamanikidza nzvimbo yekubvisa chip, iyo isina kunaka yekubvisa chip.

03 Tinya zvinhu uye kupfeka

(1) Zvinhu zvepombi

1) Tool simbi: Inonyanya kushandiswa kumaoko incisor matepi, ayo asina kujairika parizvino.

2) Cobalt-isina high-speed simbi: Parizvino, inoshandiswa zvakanyanya sepombi zvinhu, seM2 (W6Mo5Cr4V2, 6542), M3, nezvimwewo, uye kodhi yekumaka iHSS.

3) Cobalt-ine high-speed simbi: parizvino inoshandiswa zvakanyanya sepombi zvinhu, seM35, M42, nezvimwewo, iyo yekumaka kodhi iHSS-E.

4) Powder metallurgy high-speed simbi: Inoshandiswa seyepamusoro-inoshanda tepi zvinhu, kuita kunonatsiridzwa zvakanyanya kana kuchienzaniswa neaviri ari pamusoro. Nzira dzekupa mazita dzemugadziri wega wega dzakasiyana zvakare, uye iyo yekumaka kodhi ndeyeHSS-E-PM.

5) Cemented carbide zvinhu: anowanzo shandisa Ultra-yakanaka zvimedu uye yakanaka kusimba mamakisi, ayo anonyanya kushandiswa kugadzira akatwasuka nyere matepi kugadzira mapfupi chip zvinhu, senge grey cast iron, yakakwira silicon aluminium, nezvimwe.

Mapombi anonyanya kutsamira pazvinhu, uye kusarudzwa kwezvinhu zvakanaka kunogona kukwidziridza zvimiro zvematepi, zvichiita kuti ive yakakodzera kune yakakwirira-inoshanda uye yakaoma mamiriro ekushanda, uye panguva imwe chete ine hupenyu hwesevhisi hwepamusoro. Parizvino, vagadziri vepombi hombe vane mafekitori avo emidziyo kana mafomula. Panguva imwecheteyo, nekuda kwezvinetso zvekobalt zviwanikwa uye mitengo, itsva cobalt-isina high-performance high-speed steels yakabudawo.

(2) Kuvhara pombi

1) Steam oxidation: Iyo pombi inoiswa muhuputi hwemvura yakanyanya kudziya kuti igadzire firimu reoxide pamusoro, rine yakanaka adsorption kune inotonhorera, inogona kuderedza kukweshera, uye kudzivirira tepi uye zvinhu kuti zvichekwe. Inokodzera kugadzira simbi yakapfava.

2) Nitriding kurapwa: Iyo pamusoro pepombi ine nitrided kuti iite yakaomeswa layer, iyo inokodzera machining cast iron, cast aluminium uye zvimwe zvinhu zvine maturusi makuru ekupfeka.

3) Steam + Nitriding: Sanganisa zvakanakira zviri pamusoro apa zviviri.

4) TiN: yegoridhe yero yejasi, ine yakanaka yekupfeka kuoma uye lubricity, uye yakanaka yekubatisa adhesion, yakakodzera kugadzirisa zvinhu zvakawanda.

5) TiCN: yebhuruu-grey coating nekuoma kwe 3000HV uye kupisa kwekudzivirira kwe400 ° C.

6) TiN + TiCN: yakasviba yero yejasi, ine yakanakisa coating kuomarara uye lubricity, yakakodzera kugadzirisa zvinhu zvakawanda.

7) TiAlN: bhuruu-grey coating, kuoma 3300HV, kupisa kupisa kusvika 900 ° C, inogona kushandiswa kumhanyisa machining.

8) CrN: sirivheri-grey coating, yakanakisa lubricating performance, inonyanya kushandiswa kugadzira asiri-ferrous simbi.

Kupesvedzera kwekupfekedzwa kwepombi pakushanda kwepombi kuri pachena, asi parizvino, vazhinji vanogadzira uye vanogadzira machira vanoshandira pamwe kuti vadzidze machira chaiwo.

04 Elements Inobata Tapping

(1) Midziyo yekurovera

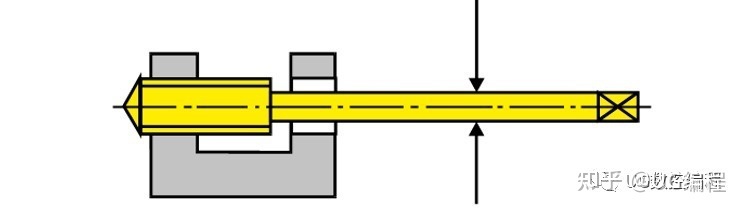

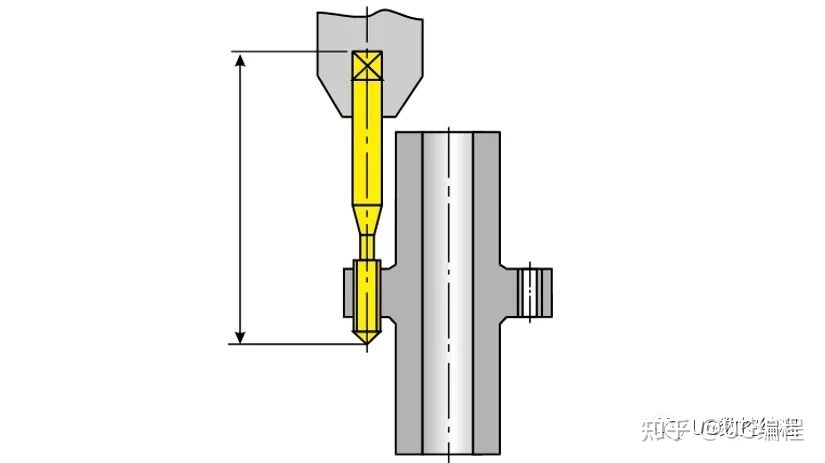

1) Chishandiso chemuchina: Inogona kukamurwa kuita yakatwasuka uye yakatwasuka nzira dzekugadzirisa. Pakubata, vertical processing iri nani pane yakachinjika kugadzirisa. Kana kutonhora kwekunze kuchiitwa mukugadziriswa kwakatwasuka, zvinodikanwa kufunga kana kutonhora kwakaringana.

2) Kubata chibatiso chekushandisa: Zvinokurudzirwa kushandisa yakakosha yekubatisa chibatiso chekubata. Chishandiso chemuchina chakasimba uye chakatsiga, uye chibatiso chekutapa chibatiso chinofarirwa. Pane zvinopesana, iyo inochinjika yekubatisa mudziyo inobata ine axial/radial muripo inofanira kushandiswa zvakanyanya sezvinobvira. . Kunze kwematepi madiki dhayamita (

(2) Zvishandiso

1) Izvo zvinhu uye kuoma kweiyo workpiece: kuomarara kweiyo workpiece zvinhu zvinofanirwa kuve yunifomu, uye kazhinji hazvikurudzirwe kushandisa tepi kugadzirisa maworkpiece anopfuura HRC42.

2) Kubaya pasi gomba: dhizaini yepasi pegomba, sarudza iyo yakakodzera drill bit; pasi gomba saizi yakarurama; pasi gomba gomba rusvingo kunaka.

(3) Processing parameters

1) Kutenderera kumhanya: Hwaro hweiyo yakapihwa yekutenderera kumhanya imhando yepombi, zvinhu, zvinhu zvinofanirwa kugadziriswa uye kuoma, mhando yemidziyo yekutepa, nezvimwe.

Kazhinji inosarudzwa zvichienderana nemaparameter akapihwa nemugadziri wepombi, kumhanya kunofanirwa kudzikiswa pasi pemamiriro anotevera:

- kusasimba kwemashini; pombi yakakura kubuda; kusakwana kutonhora;

- zvinhu zvisina kuenzana kana kuoma munzvimbo yekubata, senge majoini ekutengesa;

- pombi inorebeswa, kana tsvimbo yekuwedzera inoshandiswa;

- Recumbent plus, kunze kutonhora;

-Kushanda kwemanyorero, senge bhenji drill, radial drill, nezvimwe;

2) Kudyisa: kurovera kwakasimba, kudyisa = 1 thread pitch/revolution.

Panyaya yekutepfenyura uye nekukwana shank muripo wakasiyana:

Kudyisa = (0.95-0.98) pitches/rev.

05 Mazano ekusarudza matepi

(1) Kushivirira kwematepi emhando dzakasiyana dzemagiredhi

Sarudzo hwaro: iyo yechokwadi giredhi repombi haigone kusarudzwa uye kutariswa chete zvinoenderana negiredhi rechokwadi reshinda iri kugadzirwa.

1) Izvo zvinhu uye kuoma kweiyo workpiece kuti igadziriswe;

2) Kubata midziyo (yakadai semichina yekushandisa mamiriro, clamping zvibatiso, zvindori zvekutonhodza, nezvimwewo);

3) Iko kurongeka uye kukanganisa kwekugadzira kwepombi pachayo.

Semuenzaniso, paunenge uchigadzira tambo dze6H, paunenge uchigadzira zvikamu zvesimbi, 6H chaiyo matepi anogona kushandiswa; paunenge uchigadzira grey cast iron, nekuti dhayamita yepakati yemapombi inopfeka nekukurumidza uye kuwedzera kwemaburi escrew kudiki, zviri nani kushandisa 6HX chaiyo matepi. Tap, hupenyu huchava nani.

Chinyorwa pamusoro pechokwadi chematepi echiJapan:

1) Iyo yekucheka tapi OSG inoshandisa iyo OH precision system, iyo yakasiyana neiyo ISO standard. Iyo OH precision system inomanikidza hupamhi hwebhendi rekushivirira rose kutanga kubva kumuganhu wakaderera, uye yega yega 0.02mm inoshandiswa segiredhi rakananga, rakanzi OH1, OH2, OH3, nezvimwewo;

2) Iyo extrusion tepi OSG inoshandisa iyo RH chaiyo sisitimu. Iyo RH chaiyo sisitimu inomanikidza hupamhi hwebhendi rekushivirira rose kutanga kubva pamuganho wakaderera, uye imwe neimwe 0.0127mm inoshandiswa seyero yechokwadi, inonzi RH1, RH2, RH3, nezvimwe.

Naizvozvo, kana uchishandisa ISO precision taps kutsiva OH precision taps, hazvigone kungofungwa kuti 6H inenge yakaenzana neOH3 kana OH4 giredhi. Inoda kugadziriswa nekutendeuka, kana maererano nemamiriro chaiwo emutengi.

(2) Zviyero zvepombi

1) Inonyanya kushandiswa ndiyo DIN, ANSI, ISO, JIS, nezvimwewo;

2) Inobvumirwa kusarudza hurefu hwakakodzera hurefu, urefu hweblade uye shank size maererano nemhando dzakasiyana dzekugadzirisa zvinodiwa nevatengi kana mamiriro aripo;

3) Kupindira panguva yekugadzirisa;

(3) 6 zvinhu zvakakosha zvekusarudza tepi

1) Mhando yekugadzira tambo, metric, inch, American, nezvimwe;

2) Rudzi rwegomba rezasi rakasungwa, kuburikidza negomba kana gomba rebofu;

3) Izvo zvinhu uye kuoma kweiyo workpiece kuti igadziriswe;

4) Kudzika kweshinda yakazara ye workpiece uye kudzika kwegomba rezasi;

5) Kurongeka kunodiwa kweshinda yeworkpiece;

6) Chimiro chechimiro chepombi

Nguva yekutumira: Jul-20-2022