HRC65 Black Nano-Tech Stainless Processing Flat End Mill

Feature:

1. Tungsten simbi yakanatswa zvimedu zvakanaka + midziyo yekugadzira inotengeswa kunze kwenyika.

Isu tinoshandisa 100% tungsten carbide base material, uye tinoramba kushandisa recycle zvinhu kana hupombwe zvinhu.

2.Takatumira michina yeSACCKE kubva kuGermany kuitira kukuya zvakanaka kuti tiwane kunyatsogadzikana uye kupera kwepamusoro.

3.Kuparadzana kusina kuenzana uye kusaenzana kwehelix angle kudzivirira resonance uye kuwedzera kupera kwepamusoro kwezvikamu zvakagadziriswa.

4.HRC65.

5.Swiss inotengeswa kunze kweALoCa coating, kupisa kwekushisa uye kupisa kwekushisa kwepamusoro, kuoma kwepamusoro-kuoma.

~3500HV Coating kuoma uye 950 dhigirii anti-oxygen tembiricha.

6.Step process / full grinding spiral flute, smooth chip kubviswa panguva yekucheka-kumhanya, hapana chip accumulation / hapana chip pileup, inovandudza zvikuru kubudirira kwekugadzira uye kuvandudza workpiece kupera.

| Nyere | 4 | Material | Titanium alloy, simbi isina tsvina | ||||||||||

| Type | Flat musoro mhando | Kuoma | HRC65 | ||||||||||

| Package |

| Brand | MSK | ||||||||||

| Nyere Dyamita(mm) | Kureba kwenyere(mm) | Shank Diameter(mm) | Kureba(mm) | ||||||||||

| 1 | 3 | 4 | 50 | ||||||||||

| 1.5 | 4 | 4 | 50 | ||||||||||

| 2 | 6 | 4 | 50 | ||||||||||

| 2.5 | 7 | 4 | 50 | ||||||||||

| 3 | 8 | 4 | 50 | ||||||||||

| 4 | 11 | 4 | 50 | ||||||||||

| 5 | 13 | 6 | 50 | ||||||||||

| 6 | 15 | 6 | 50 | ||||||||||

| 8 | 20 | 8 | 60 | ||||||||||

| 10 | 25 | 10 | 75 | ||||||||||

| 12 | 30 | 12 | 75 | ||||||||||

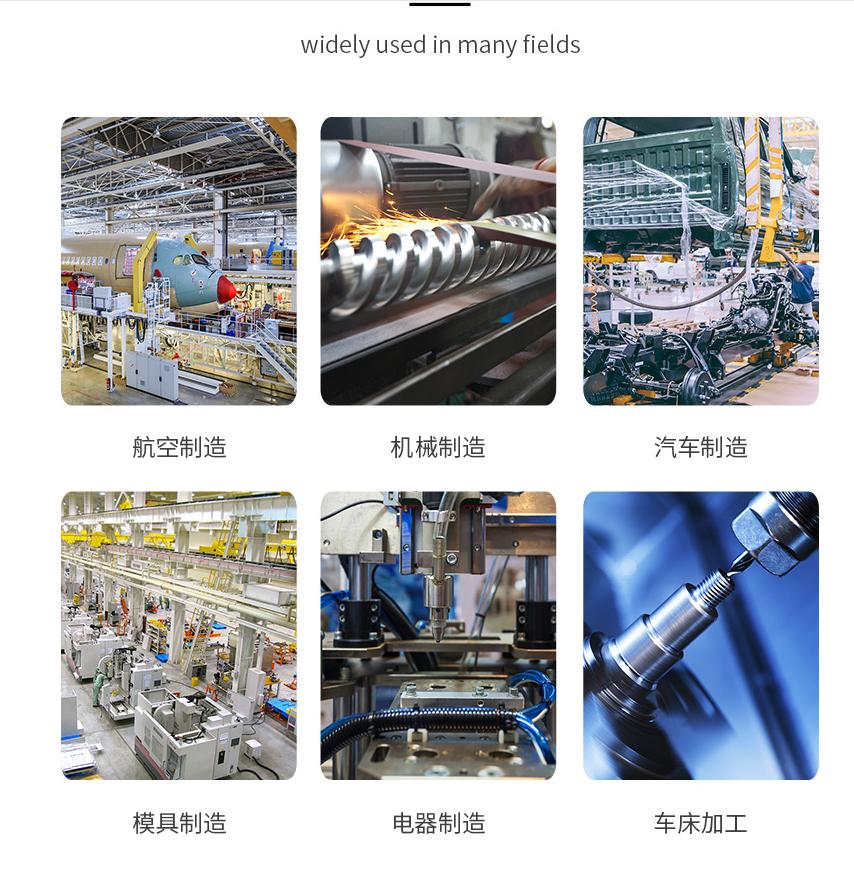

Shandisa:

Inoshandiswa zvakanyanya mundima dzakawanda

Aviation Manufacturing

Machine Production

Mugadziri wemotokari

Kugadzira mold

Electrical Manufacturing

Lathe processing