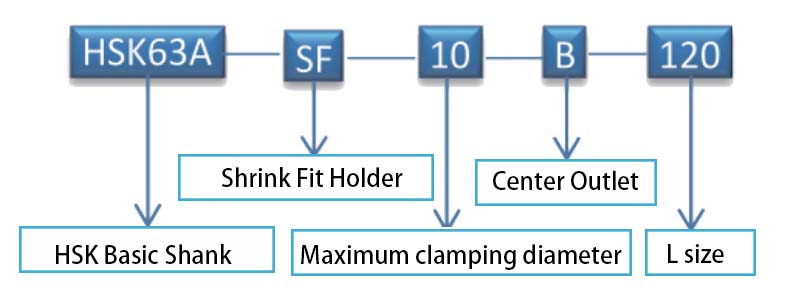

Shrink Chucks – Reliable Heat Shrinkfit Tool Holder for Enhanced Performance

Features

1.Clamps cylindrical straight shank carbide and HSS tools requiring h6 accuracy in the shank section.

2.Made of special heat-resistant steel, suitable for induction heat shrink machines, shank concentricity ≤ 0.003mm, extended version with 4 screw holes for precision balancing.

3.Precision dynamically balanced to 30,000 rpm with a maximum unbalance of U < 1 gmm.

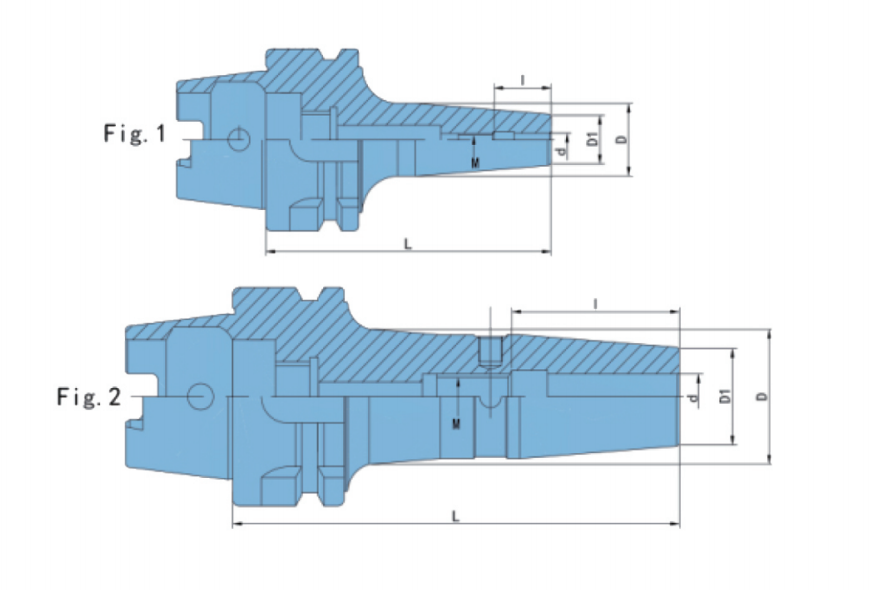

| Item number | model number | L | 1 | D | D1 | d | M | Fig | Weight |

| DBT30SF4B 80 | BT30-SF4B -80★ | 80 | 20 | 20 | 14 | 4 | / | 1 | 0.42 |

| SF4B 120 | -SF4B-120★ | 120 | 23.148 | 2 | 0.51 | ||||

| SF6B 80 | -SF6B -80 | 80 | 36 | 27 | 21 | 6 | M5x15 | 1 | 0.64 |

| SF6B 120 | -SF6B-120 | 120 | 30.148 | 2 | 0.59 | ||||

| SF8B 80 | -SF8B -80 | 80 | 27 | 8 | M6x15 | 1 | 0.56 | ||

| SF8B 120 | -SF8B -120 | 120 | 30.148 | 2 | 0.60 | ||||

| SF10B 80 | -SF10B-80 | 80 | 41 | 30 | 24 | 10 | M8x1 | 1 | 0.66 |

| SF10B120 | -SF10B-120 | 120 | 35.148 | 2 | 0.65 | ||||

| SF12B 80 | -SF12B-80 | 80 | 47 | 30 | 12 | M11x1 | 1 | 0.66 | |

| SF12B120 | -SF12B-120 | 120 | 35.148 | 2 | 0.67 | ||||

| SF14B 80 | -SF14B-80 | 80 | 34 | 27 | 14 | M11x1 | 1 | 0.58 | |

| SF14B120 | -SF14B-120 | 120 | 37.148 | 2 | 0.72 | ||||

| SF16B 80 | SF16B-80 | 80 | 50 | 34 | 16 | 1 | 0.60 | ||

| SF16B120 | -SF16B-120 | 120 | 37.148 | 2 | 0.75 | ||||

| SF18B 80 | -SF18B-80 | 80 | 42 | 33 | 18 | M14x1 | 1 | 0.79 | |

| SF18B120 | -SF18B-120 | 120 | 2 | 0.84 | |||||

| SF20B 80 | -SF20B-80 | 80 | 52 | 42 | 20 | 1 | 0.73 | ||

| SF20B120 | -SF20B-120 | 120 | 2 | 0.85 | |||||

| DBT4OSF4B 90 | BT40-SF4B -90★ | 90 | 20 | 20 | 14 | 4 | / | 1 | 1.01 |

| SF4B 120 | -SF4B-120★ | 120 | 23.148 | 2 | 1.07 | ||||

| SF4B 150 | -SF4B-150★ | 150 | 26.296 | 2 | 1.13 | ||||

| SF6B 90 | -SF6B -90 | 90 | 36 | 27 | 21 | 6 | M5 | 1 | 1.21 |

| SF6B 120 | -SF6B-120 | 120 | 30.148 | 2 | 1.10 | ||||

| SF6B 150 | -SF6B -150 | 150 | 33.296 | 2 | 1.17 | ||||

| SF8B 90 | -SF8B -90 | 90 | 27 | 8 | M6 | 1 | 1.21 | ||

| SF8B 120 | -SF8B-120 | 120 | 30.148 | 2 | 1.18 | ||||

| SF8B 150 | -SF8B-150 | 150 | 33.296 | 2 | 1.25 | ||||

| SF10B 90 | -SF10B-90 | 90 | 41 | 30 | 24 | 10 | M8x1 | 1 | 1.20 |

| SF10B120 | -SF10B-120 | 120 | 35.148 | 2 | 1.21 | ||||

| SF10B150 | -SF10B-150 | 150 | 38.296 | 2 | 1.27 |

| Item number | model number | L | 1 | D | D1 | d | M | Fig | Weight |

| DBT40SF12B 90 | BT40-SF12B-90 | 90 | 47 | 30 | 24 | 12 | M11x1 | 1 | 1.19 |

| SF12B120 | -SF12B-120 | 120 | 35.148 | 2 | 1.24 | ||||

| SF12B150 | -SF12B-150 | 150 | 38.296 | 1.32 | |||||

| SF14B 90 | -SF14B-90 | 90 | 34 | 27 | 14 | M11x1 | 1 | 1.24 | |

| SF14B120 | -SF14B-120 | 120 | 37.148 | 2 | 1.28 | ||||

| SF14B150 | -SF14B-150 | 150 | 40.296 | 1.38 | |||||

| SF16B 90 | -SF16B-90 | 90 | 50 | 34 | 16 | 1 | 1.21 | ||

| SF16B120 | -SF16B-120 | 120 | 37.148 | 2 | 1.30 | ||||

| SF16B150 | -SF16B-150 | 150 | 40.296 | 1.42 | |||||

| SF18B 90 | -SF18B -90 | 90 | 42 | 33 | 18 | M14x1 | 1 | 1.40 | |

| SF18B120 | -SF18B-120 | 120 | - | 2 | 1.19 | ||||

| SF18B150 | -SF18B-150 | 150 | 48.296 | 1.57 | |||||

| SF20B 90 | -SF20B-90 | 90 | 52 | 42 | 20 | 1 | 1.37 | ||

| SF20B120 | -SF20B-120 | 120 | - | 2 | 1.31 | ||||

| SF20B150 | -SF20B-150 | 150 | 48.296 | 1.52 | |||||

| SF25 B90 | -SF25B-90 | 90 | 58 | 52 | 44 | 25 | M18x1 | 1 | 1.64 |

| SF25B120 | -SF25B-120 | 120 | - | 2 | 1.41 | ||||

| SF25B150 | -SF25B-150 | 150 | - | 1.71 | |||||

| SF32B100 | -SF32B-100 | 100 | 1.64 | ||||||

| DBT50SF6B 100 | BT50-SF6B-100 | 100 | 36 | 27 | 21 | 6 | M5x15 | 1 | 3.92 |

| SF6B 120 | -SF6B -120 | 120 | 30.148 | 2 | 3.55 | ||||

| SF6B 150 | -SF6B-150 | 150 | 33.296 | 3.69 | |||||

| SF6B 200 | -SF6B-200 | 200 | 37.452 | 3.89 | |||||

| SF8B 100 | -SF8B-100 | 100 | 27 | 8 | M6x15 | 1 | 3.92 | ||

| SF8B 120 | -SF8B-120 | 120 | 30.148 | 2 | 3.69 | ||||

| SF8B 150 | -SF8B -150 | 150 | 33.296 | 3.79 | |||||

| SF8B 200 | -SF8B-200 | 200 | 37.452 | 4.02 | |||||

| SF10B100 | -SF10B-100 | 100 | 41 | 30 | 24 | 10 | M8x1 | 1 | 3.90 |

| SF10B120 | -SF10B-120 | 120 | 35.148 | 2 | 3.59 | ||||

| SF10B150 | -SF10B-150 | 150 | 38.296 | 3.77 | |||||

| SF10B200 | -SF10B-200 | 200 | 40.453 | 4.02 | |||||

| SF12B100 | -SF12B-100 | 100 | 47 | 30 | 12 | M11x1 | 1 | 3.94 | |

| SF12B120 | -SF12B-120 | 120 | 35.148 | 2 | 3.73 | ||||

| SF12B150 | -SF12B-150 | 150 | 38.296 | 3.82 | |||||

| SF12B200 | -SF12B-200 | 200 | 40.453 | 4.07 | |||||

| SF14B100 | -SF14B-100 | 100 | 34 | 27 | 14 | M11x1 | 1 | 4.02 | |

| SF14B120 | -SF14B-120 | 120 | 37.148 | 2 | 3.78 | ||||

| SF14B150 | -SF14B-150 | 150 | 40.296 | 3.83 | |||||

| SF14B200 | -SF14B-200 | 200 | 43.449 | 4.16 | |||||

| SF16B100 | -SF16B-100 | 100 | 50 | 34 | 16 | 1 | 3.96 | ||

| SF16B120 | -SF16B-120 | 120 | 37.148 | 2 | 3.74 | ||||

| SF16B150 | -SF16B-150 | 150 | 40.296 | 3.89 | |||||

| SF16B200 | -SF16B-200 | 200 | 43.449 | 4.19 | |||||

| SF18B100 | -SF18B-100 | 100 | 42 | 33 | 18 | M14x1 | 1 | 4.12 | |

| SF18B120 | -SF18B-120 | 120 | 2 | 3.79 | |||||

| SF18B150 | -SF18B-150 | 150 | 48.296 | 3.97 | |||||

| SF18B200 | -SF18B-200 | 200 | 51.035 | 4.30 | |||||

| SF20B100 | -SF20B-100 | 100 | 52 | 42 | 20 | 1 | 4.06 | ||

| SF20B120 | -SF20B-120 | 120 | 2 | 3.78 | |||||

| SF20B150 | -SF20B-150 | 150 | 48.296 | 3.94 | |||||

| SF20B200 | -SF20B-200 | 200 | 51.035 | 4.22 | |||||

| SF25B100 | -SF25B-100 | 100 | 58 | 52 | 44 | 25 | M18x1 | 1 | 4.36 |

| SF25B120 | -SF25B-120 | 120 | 2 | 3.89 | |||||

| SF25B150 | -SF25B-150 | 150 | 4.17 | ||||||

| SF25B200 | -SF25B-200 | 200 | 60.453 | 4.67 | |||||

| SF32B100 | -SF32B-100 | 100 | 62 | 52 | 32 | 1 | 4.15 | ||

| SF32B120 | -SF32B-120 | 120 | 2 | 3.99 | |||||

| SF32B150 | -SF32B-150 | 150 | 4.37 | ||||||

| SF32B200 | -SF32B-200 | 200 | 60.453 | 5.01 |

Why Choose Us

Factory Profile

About Us

FAQ

Q1: who are we?

A1: Founded in 2015, MSK (Tianjin) Cutting Technology CO.Ltd has grown continuously and passed Rheinland ISO 9001

authentication.With German SACCKE high-end five-axis grinding centers, German ZOLLER six-axis tool inspection center, Taiwan PALMARY machine and other international advanced manufacturing equipment, we are committed to producing high-end,professional and efficient CNC tool.

Q2: Are you trading company or manufacturer?

A2: We are the factory of carbide tools.

Q3: Can you send products to our Forwarder in China?

A3: Yes,if you have Forwarder in China,we will glad to send products to him/her.Q4: What terms of payment are acceptable?

A4: Normally we accept T/T.

Q5: Do you accept OEM orders?

A5: Yes, OEM and customization are available, and we also provide label printing service.

Q6: Why should you choose us?

A6:1) Cost control - purchasing high-quality products at an appropriate price.

2) Quick response - within 48 hours, professional personnel will provide you with a quote and address your concerns.

3) High quality - The company always proves with sincere intention that the products it provides are 100% high-quality.

4) After sales service and technical guidance - The company provides after-sales service and technical guidance according to customer requirements and needs.